Liquid flow alkalization method and alkalization device

A liquid flow and liquid technology, applied in the field of chemical analysis, can solve the problems of reducing the accuracy of analysis results, difficult to achieve trace analysis, unsatisfactory alkalization effect, etc., to avoid human harm and environmental pollution, and good alkalization effect , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is further described in conjunction with the accompanying drawings and examples.

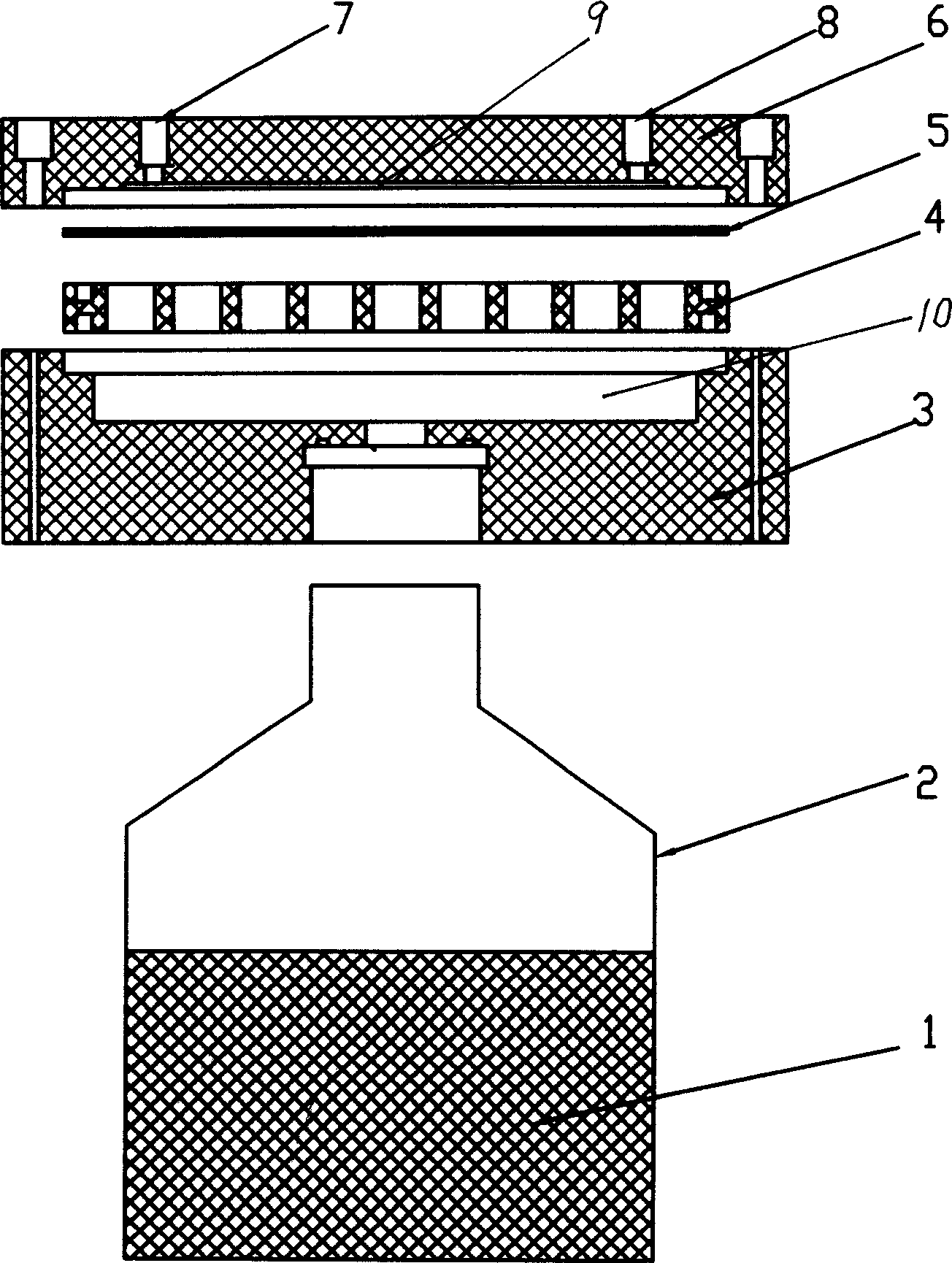

[0011] The bottle mouth of the alkalization bottle 2 filled with strong alkali liquid diisopropylamine 1 is connected with the base 3 in the alkalization pool by thread sealing, and the joint of the base 3 and the upper cover 6 is provided with a porous membrane support in the inner cavity. The microporous polytetrafluoroethylene film 5 on the body 4, the pore diameter of the film 5 is 60 μm, the size is basically the same, densely and evenly distributed, the film and the support are rectangular, 90 mm long and 13 mm wide, and the support is equipped with seals around the upper and lower sides. lock up. There is a cavity 9 with a height of 1.2 mm above the film 5 , and a cavity 10 communicating with the alkalization bottle is located below the support 4 .

[0012] When working, the liquid flows in from the inlet 7 on the upper cover and flows out from the outlet 8. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com