Apparatus for preventing against resonant vibration

A technology of transmission device and vibration system, which is applied in the directions of propulsion engine, transportation and packaging, vibration suppression adjustment, etc., can solve the problems of easy interference, expensive mechanical structure, etc., achieve short response time, easy quantification, and reduce the number of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

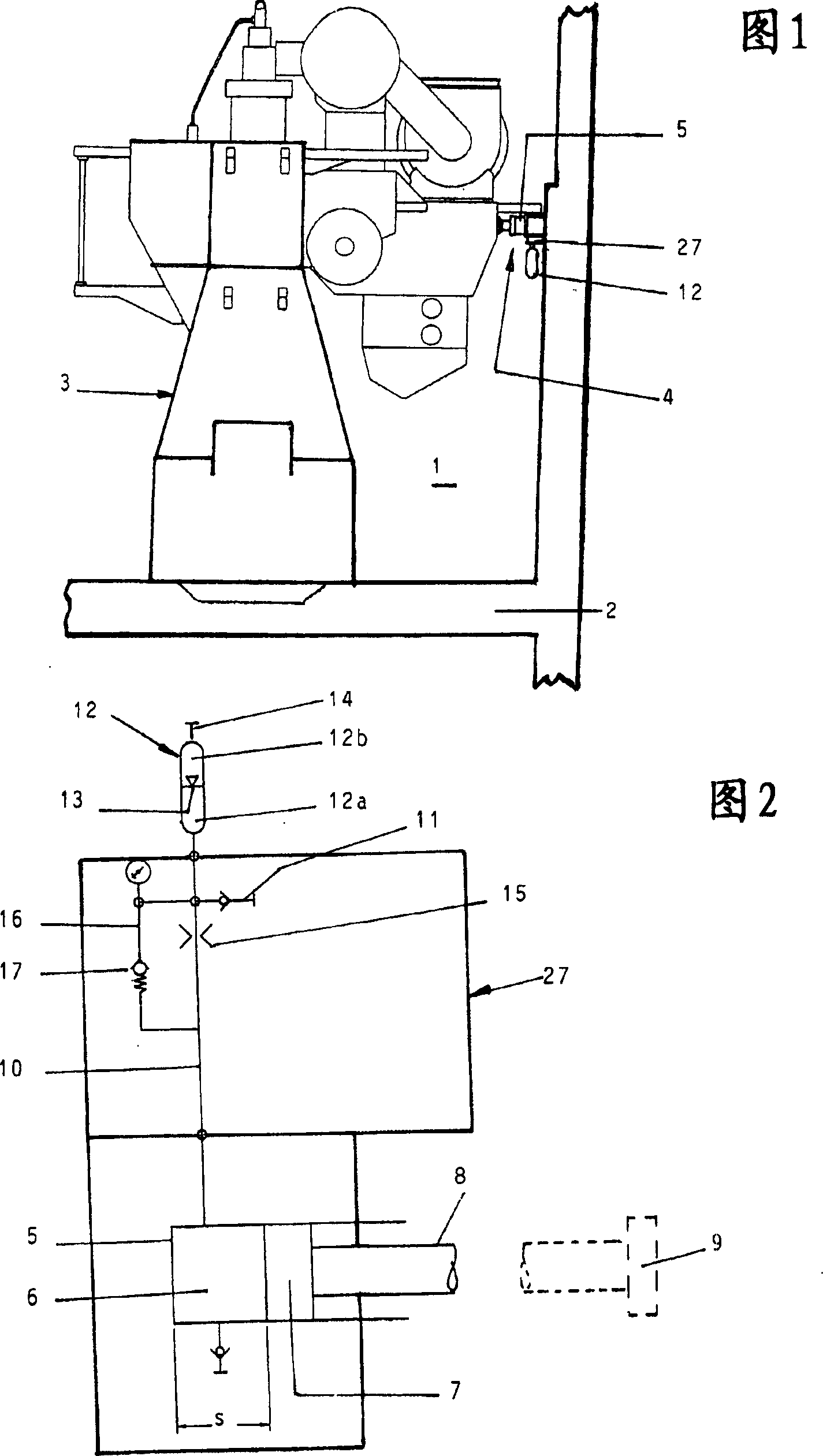

[0029] FIG. 1 shows an engine 3 installed in the engine room 1 of a ship represented by a support structure 2 as a drive machine for the ship. Preferably, it is a two-stroke large diesel engine in crosshead design. The structure and mode of operation of such engines are known per se.

[0030] The motor 3 is laterally supported in the region above it, ie in the region of its upper passage. There is therefore provided at least one bearing device 4 mounted between the support structure of the side wall of the nacelle 1 and the engine part facing the side wall, ie the discharge channel of the exhaust gas turbocharger. Expediently, a plurality of such bearing devices 4 can be arranged along the length of the engine 3 . Also provided on both sides of the engine 3 are opposing bearings 4 .

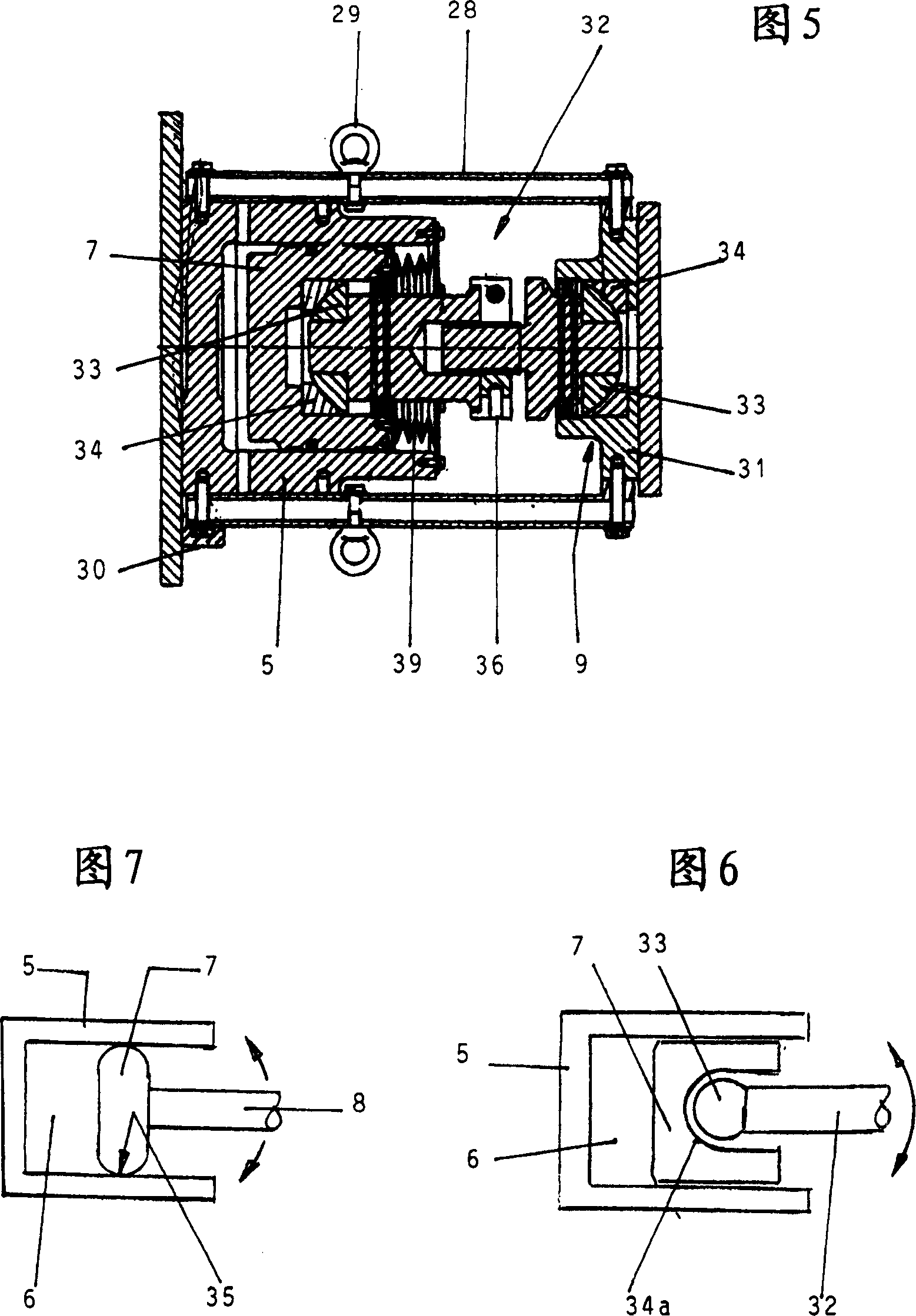

[0031] The bearing device 4 is designed as a single-acting, hydraulic bearing device. As can best be seen in FIG. 2, the support device comprises at least one cylinder 5 with a working chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com