Seven-layer coextrusion membrane for transfusion and its production method

A film and outer layer technology for infusion, which is applied in the field of co-extrusion film for infusion and its manufacturing, and can solve the problems of compressibility, mechanical strength and optical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

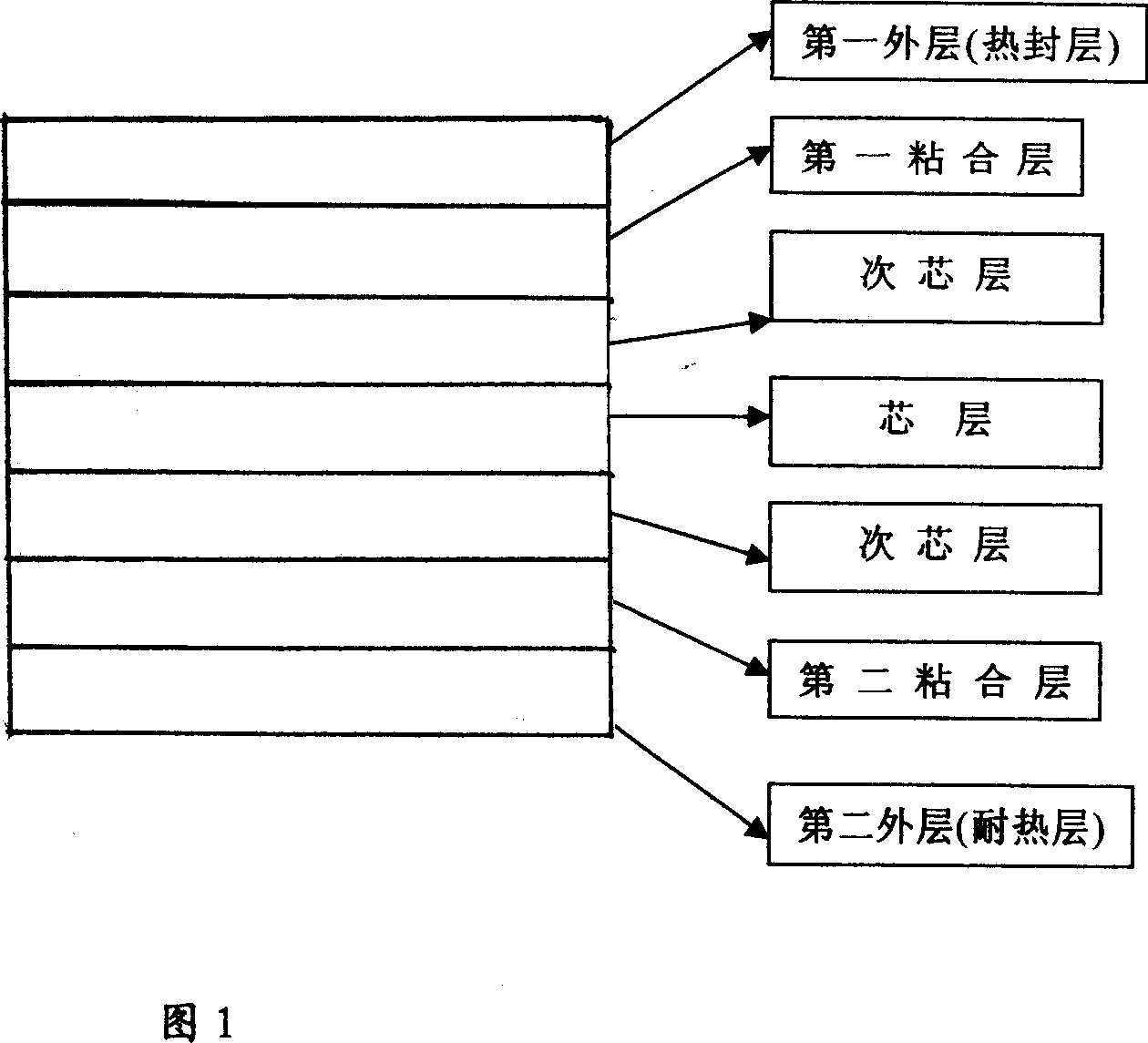

[0039] The film shown in Figure 1 in the production process developed by the present invention has a seven-layer structure and is used to make flexible packaging bags for packaging and using liquid medicine. The medical liquids packaged and used in this way include: saline solution, glucose solution, cleaning solution, dialysate and various other medical liquids. The seven-layer film includes a core layer, a first outer layer, a second outer layer, a first adhesive layer between the first outer layer and the core layer, a second adhesive layer between the second outer layer and the core layer, and two a sub-core layer.

[0040] A: It is the first outer layer, and the material is homopolypropylene or copolymerized polypropylene, high-density polyethylene, or any mixture thereof;

[0041] B: is the first adhesive layer, and the material is any one of modified polypropylene or metallocene polypropylene or any mixture thereof;

[0042]C: is the sub-core layer, the material is me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com