Double-head cutting saw

A cutting saw and double-headed saw technology, which is applied in the direction of sawing machine, metal sawing equipment, metal processing, etc., can solve the problem that the shape and position tolerance and dimensional accuracy are difficult to meet the process standard requirements, and the butt welding seam between the heat sink and the header pipe is not good. Solve problems such as tightness, welding stress and deformation, and achieve the effects of stable product quality, high use value and promotion value, and product quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

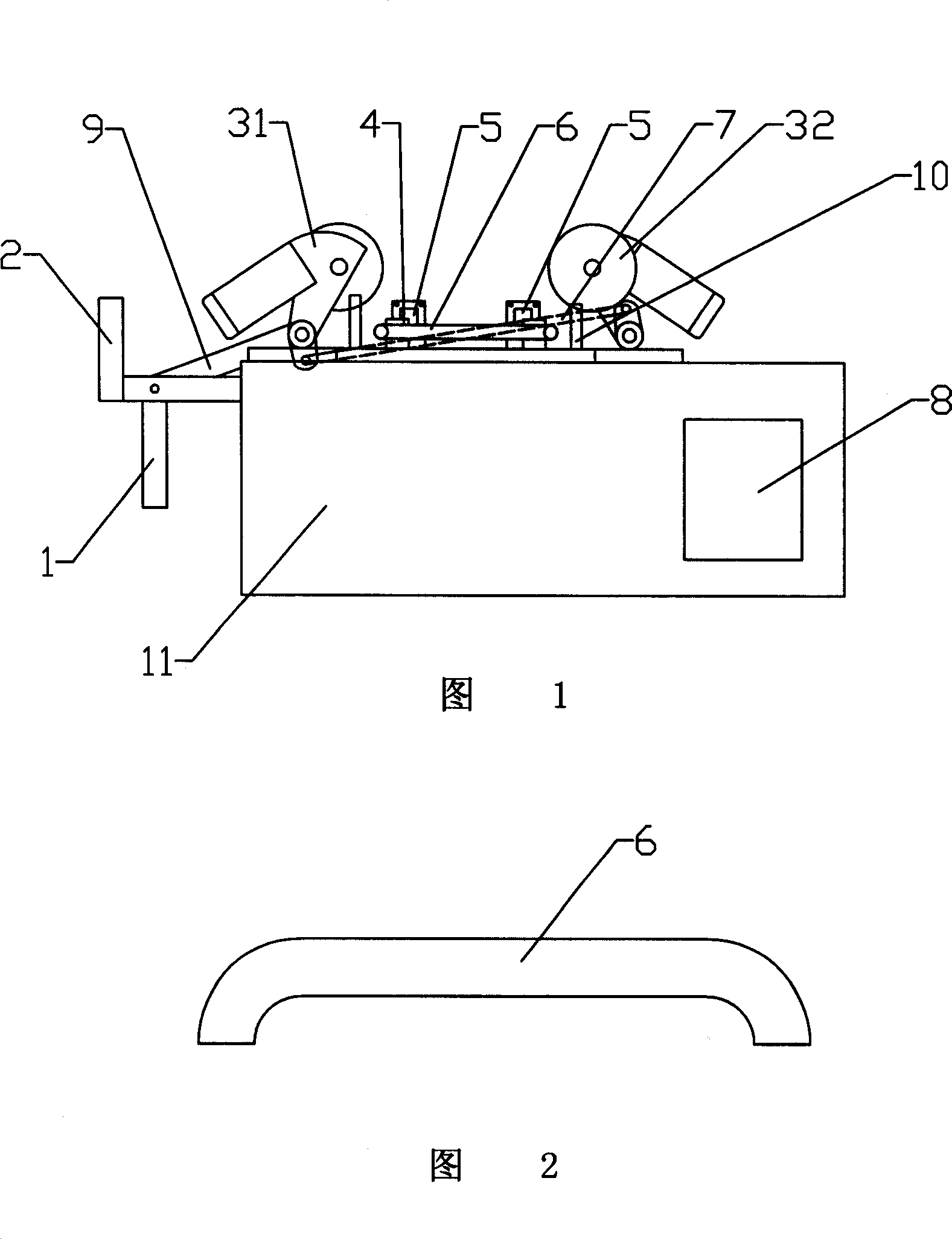

[0017] An embodiment, as shown in FIG. 1 , a double-head saw for cutting includes a machine base 11 and a control cabinet. The machine base 11 is provided with a working platform, and an adjustment limit rod 10 is arranged on the working platform. The working platform is provided with a tire membrane 4 and an air cap 5 for fixing the workpiece. The left side of the working platform is fixedly provided with a first cutting saw 31, and the right side is fixedly provided with a second cutting saw 32. The first cutting saw 31 and the second cutting saw 32 run the control top 2 and the feed gas top 1. A connecting rod 9 for controlling the cutting stroke is provided between the control top 2 and the first cutting saw 31. A limit switch is provided on the rod 9, and a transmission rod 7 is provided between the first cutting saw 31 and the second cutting saw 32. The first cutting saw 31 and the second cutting saw 32 are electrically connected to the control cabinet. , put the elbow 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com