Oxide magnetic material and sintered magnet

A technology of magnetic materials and sintered magnets, which is applied in the fields of magnetism of inorganic materials, manufacturing of inductors/transformers/magnets, electrical components, etc., and can solve problems such as inability to meet high coercive force and high squareness ratio, inability to apply motors, and poor squareness ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

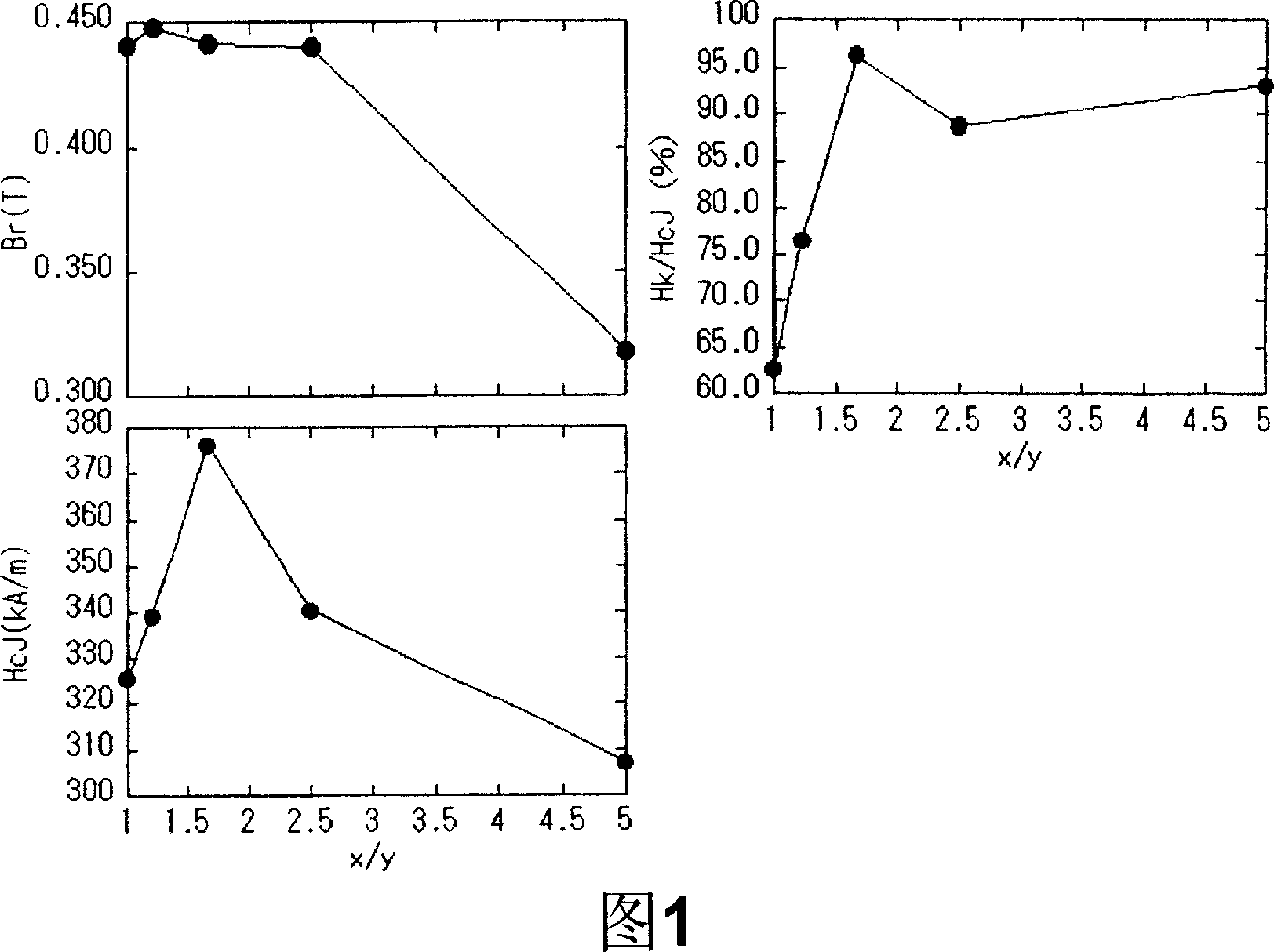

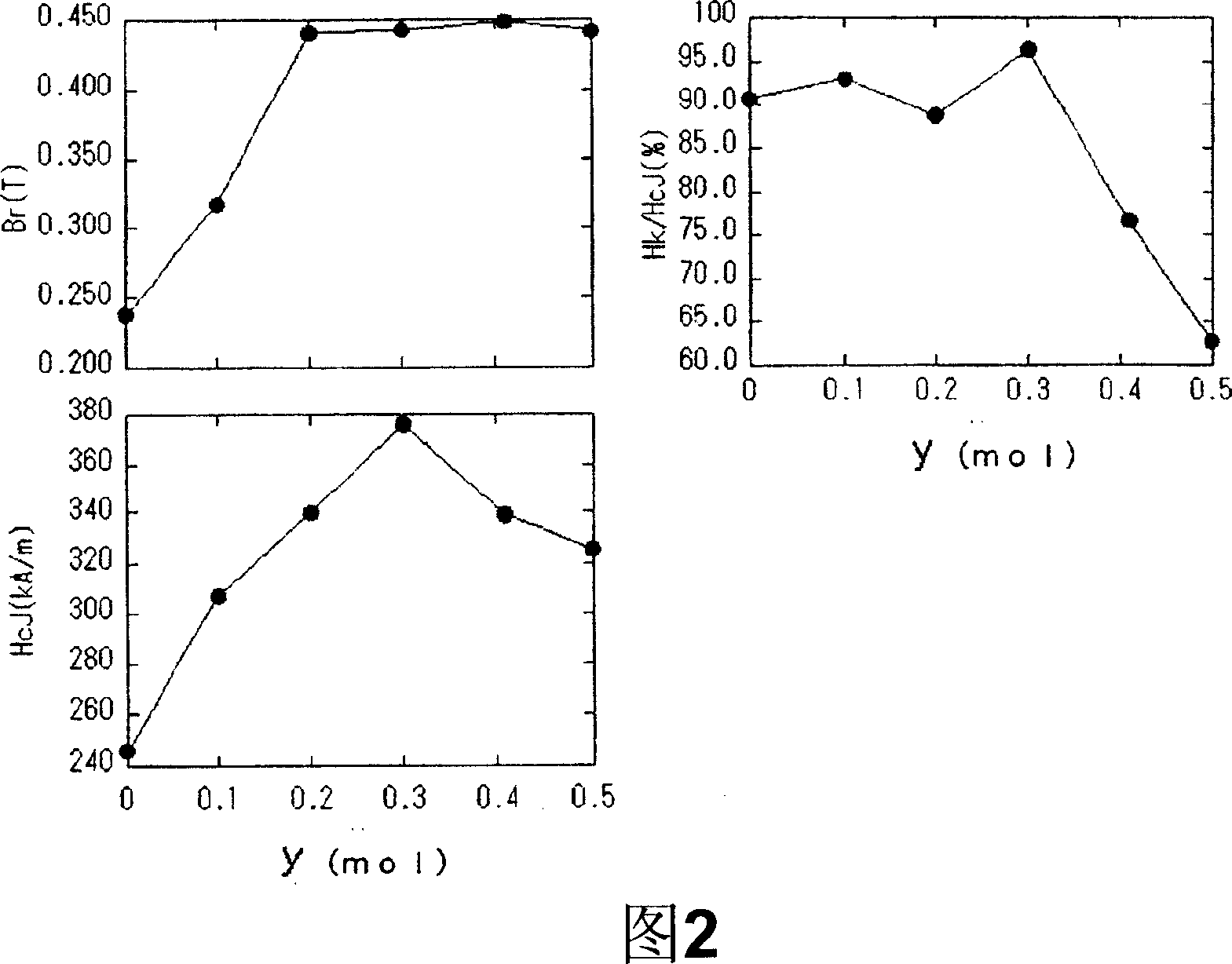

[0094] Prepare CaCO 3 Powder, La 2 o 3 Powder, Fe 2 o 3 Powder (particle size 0.6μm) and Co 3 o 4 And with each powder, so that in formula (1-x)CaO·(x / 2)La 2 o 3 ·(n-y / 2)Fe 2 o 3 · In yCoO, x=0.5, 1≤x / y, 0≤y≤0.5, n=5.4. The obtained raw material powders were mixed in a wet ball mill for 4 hours, dried and sized. Next, it fired at 1300 degreeC for 3 hours in air|atmosphere, and obtained the powdery fired body.

[0095] Next, 0.6% by mass of CaCO in terms of CaO was added to the calcined body. 3 Powder, 0.45% by mass SiO 2 The powder is finely pulverized in a wet ball mill using water as a solvent until the average particle size of the air permeation method reaches 0.55 μm. The solvent in the obtained finely pulverized slurry was removed, and pressure molding was performed in a magnetic field. Press molding was performed so that the pressing direction of the press was parallel to the direction of the magnetic field, and the magnetic field strength was 13 kOe. The ...

Embodiment 2

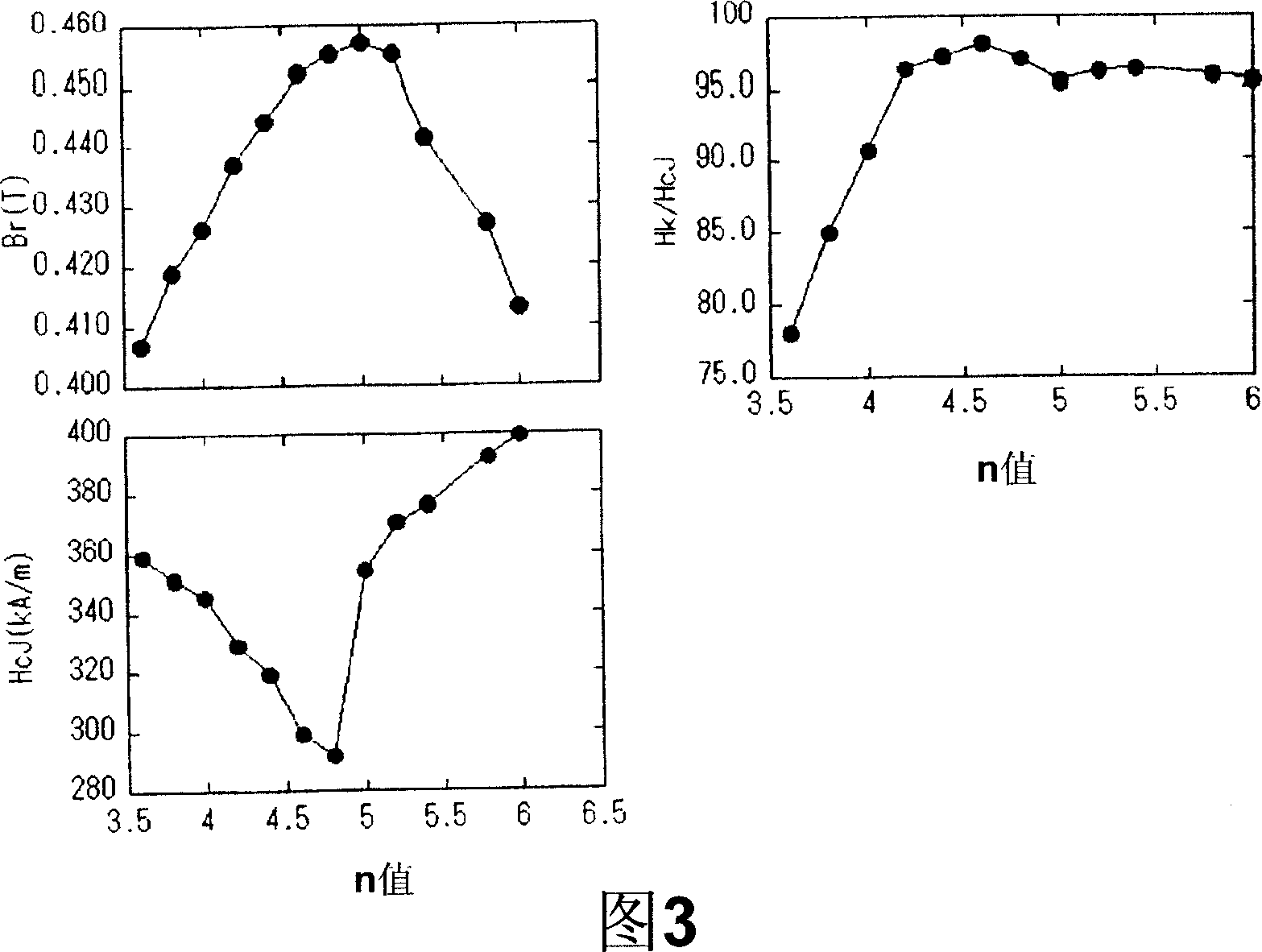

[0100] In formula (1-x)CaO·(x / 2)La 2 o 3 ·(n-y / 2)Fe 2 o 3 - In yCoO, except having set x=0.5, y=0.3, x / y=1.67, and 3.6≤n≤6.0, it carried out similarly to Example 1, and produced the sintered magnet. The magnetic properties of the obtained sintered magnets were measured. Fig. 3 shows the measurement results of residual magnetic flux density Br, coercive force HcJ, and squareness ratio Hk / HcJ with n value as the horizontal axis.

[0101] It can be seen from Figure 3 that in the range of 4.0≤n≤6.0, it shows a high squareness ratio of more than 85%, and in the range of 4.8≤n≤5.8, it shows a high squareness ratio of more than 90%, and further, in the range of 5.0≤ In the range of n≤5.4, high magnetic properties such as Br of 0.44T or higher and HcJ of 340kA / m (4.27kOe) or higher are obtained, and when n=5.2, properties of HcJ of 370kA / m or higher and Br of 0.45T or higher are obtained .

Embodiment 3

[0103] In Example 2, using the composition of n=5.2, the magnetic properties when the sintering temperature is changed between 1150°C and 1190°C are shown in Table 1.

[0104] Sintering temperature

[0105] It can be seen from Table 1 that when the sintering temperature is on the low temperature side, a high HcJ of 370kA / m (4.65kOe) and an Hk / HcJ of more than 95% are obtained; when the sintering temperature is on the high temperature side, a high Br of 0.46T or more and a Hk of more than 90% are obtained. / HcJ.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com