A method for preparing nano compound resin prosthetics material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

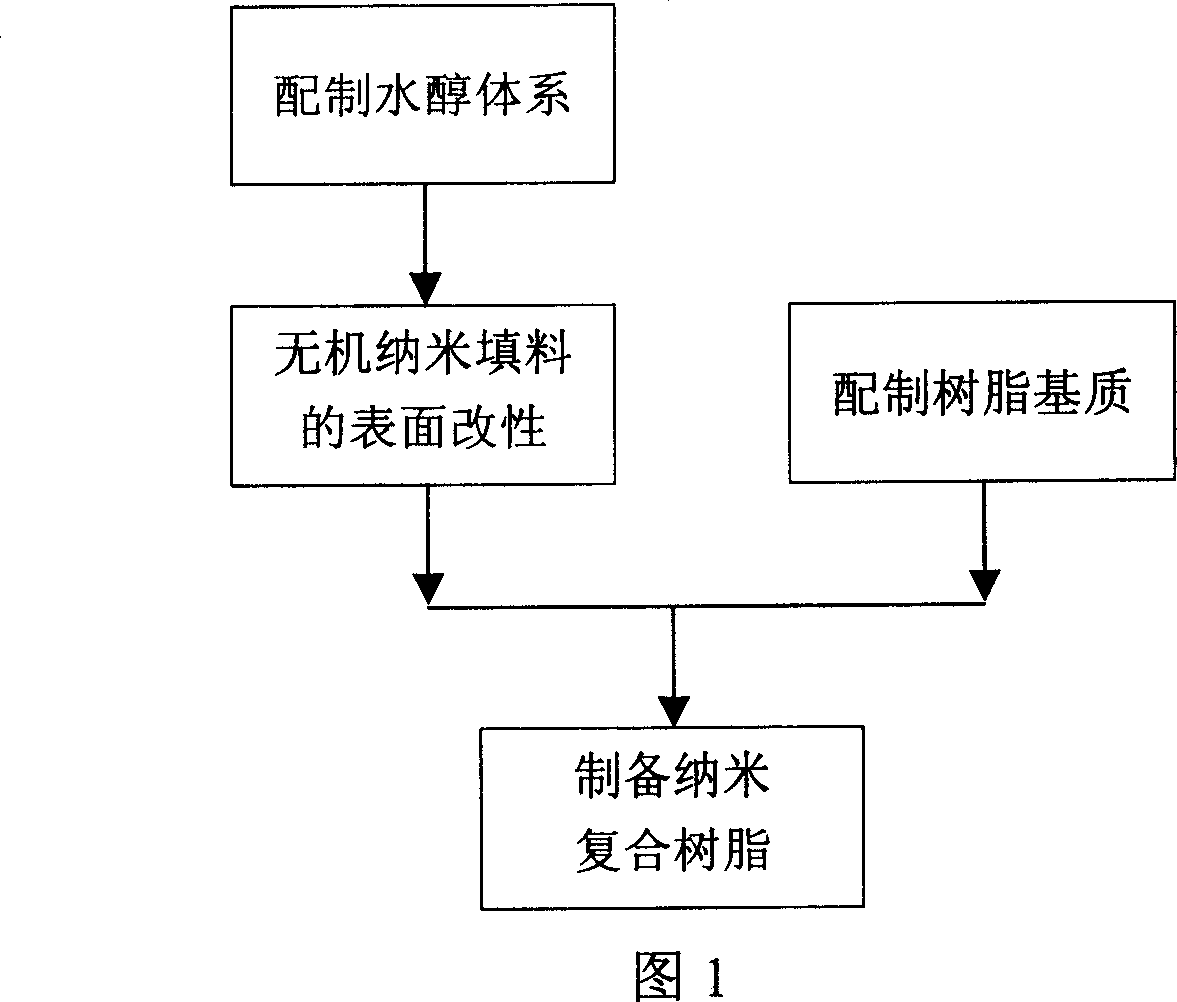

[0027] As shown in Fig. 1, the present invention provides a kind of preparation method of nanocomposite resin oral restorative material, and it comprises the steps:

[0028] Prepare the hydroalcoholic system: hydrolyze the silane coupling agent under the catalysis of acetic acid to form a hydroalcoholic system containing the coupling agent;

[0029] Surface modification of inorganic nano-fillers: adding nano-inorganic powders to a water-alcohol system containing a coupling agent for ultrasonic dispersion, after the reaction is complete, washing and drying to obtain modified inorganic nano-fillers;

[0030] Preparation of resin matrix: Dilute the resin monomer with an appropriate amount of diluent to form a resin matrix with good mixing properties;

[0031] Preparation of nanocomposite resin: under the condition of avoiding light, add the prepared resin matrix to the photoinitiator and co-initiator, after stirring evenly, then add the modified inorganic nano filler, after mixin...

experiment example 1

[0045] Hydrolyze 2g of KH-570 under the action of acetic acid, add 100ml of hydroalcoholic solution (V water: V alcohol is 5:95), then add 20g of nano-hydroxyapatite powder, ultrasonically disperse for 60min, then move to an oven at 80 Dry at ℃ for 6h. Washing with the above-mentioned water-alcohol system, repeating the drying step, and pulverizing after drying.

[0046]Prepare 10g of composite resin: add 0.8865g of triethylene glycol dimethacrylate (TEGDMA) to 2.0685g of bisphenol A glycidyl methacrylate (Bis-GMA) to dilute, and stir evenly with a spatula to make it have a good Miscibility; under dark conditions, add 0.015g photoinitiator camphorquinone and 0.03g dimethylaminoethyl methacrylate (DMAEM) to the prepared resin matrix, stir evenly, add 7g of the above-mentioned modified inorganic Nano filler, after mixing evenly. Place it in a vacuum desiccator for 12 hours to remove air bubbles between the resins, and prepare a nanocomposite resin material. The composite resi...

experiment example 2

[0048] 3gKH-570 is hydrolyzed under the effect of acetic acid, and the hydroalcoholic solution of adding 100ml (V 水 :V 醇 3:7), then add 15g of barium-aluminum glass powder, ultrasonically disperse for 60min, then move to an oven and dry at 70°C for 8h. Washing with the above-mentioned water-alcohol system, repeating the drying step, and pulverizing after drying.

[0049] Prepare 10g of composite resin: Add 0.9850g of triethylene glycol dimethacrylate (TEGDMA) to 1.4775g of urethane dimethacrylate (UDMA) to dilute, and stir evenly with a spatula to make it have good mixing properties ; Under dark condition, add 0.0125g photoinitiator camphorquinone and 0.025g dimethylaminoethyl methacrylate (DMAEM) to the prepared resin matrix, after stirring, add the above-mentioned modified inorganic nanofiller of 7.5g , after mixing evenly. Place it in a vacuum desiccator for 14 hours to remove air bubbles between the resins, and prepare a nanocomposite resin material. The composite resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com