Dust settling fine coke reblending coal coking method and its technology

A technology for blending coal for coking and coking powder, applied in coke ovens, petroleum industry and other directions, can solve the problems of limitation, high labor intensity of workers, increase investment in equipment and sites, etc., and achieve comprehensive cost reduction, shorten coking time, and reduce coking heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

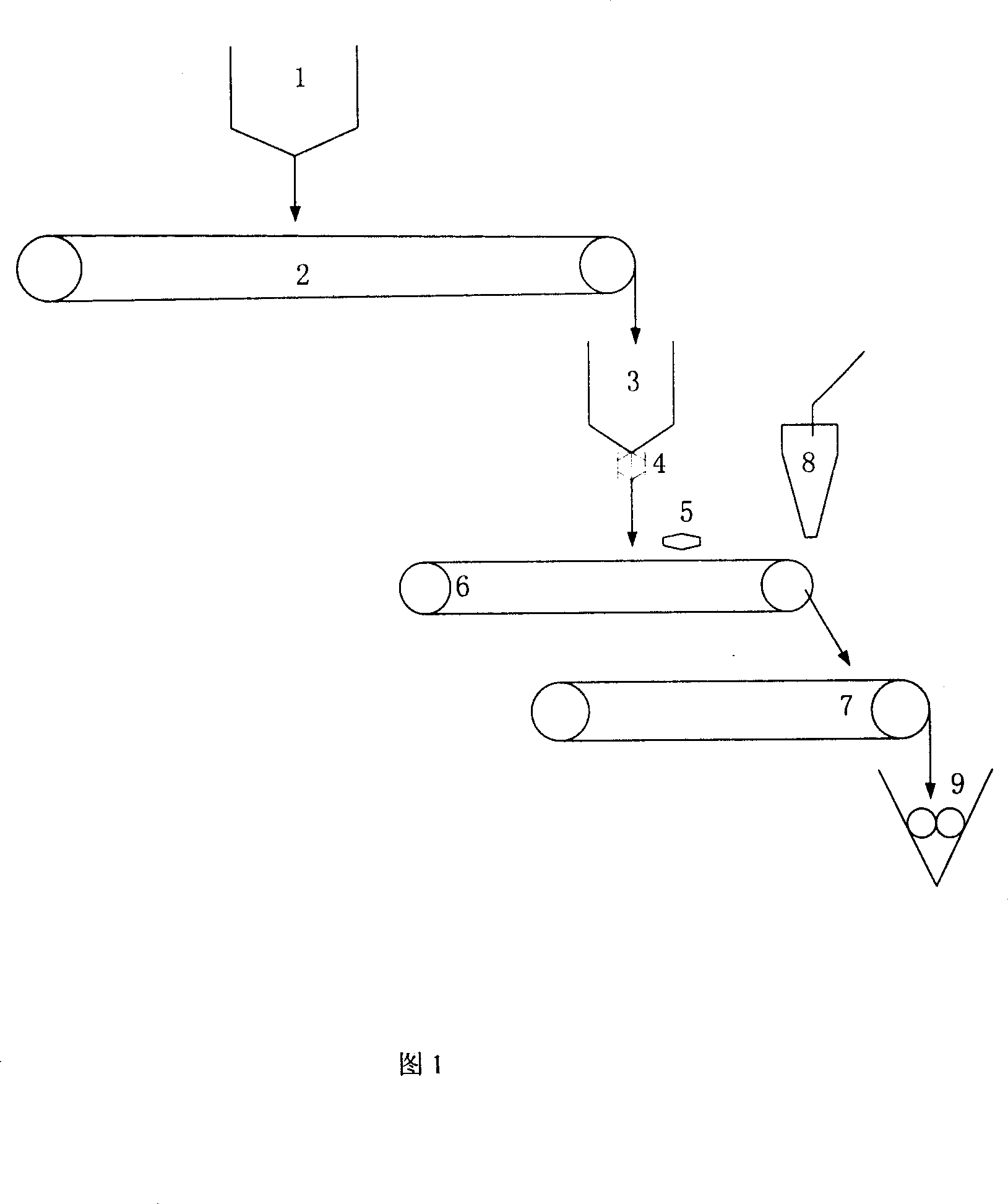

[0011] The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0012] The present invention relates to a coking method and process of coke powder back blending coal, which directly uses dedusted coke powder that does not need to be pulverized or ground as a thinning agent to replace clean coal and mix it with other coking coal evenly before entering the coking chamber of the coke oven for coking. .

[0013] Coke powder from CDQ environment dust removal, CDQ process dust removal coke powder, and coking ground dust removal station dust removal powder are collected and mixed uniformly in a ratio of 5:4:1, and then sent to the silo (1). 1) After the sealed belt conveyor (2) enters the batching trough (3) for processing, it is sent from the batching tray (4) to the conveyor (6) equipped with an electronic scale (5), and the batching rate is ≤5%. Quantitatively sent to the coal blending room pulverizer (9) on the belt con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com