Carried catalyst electroplating method for hydrolyzing hydroborates to produce hydrogen

A technology for producing hydrogen and borohydride by hydrolysis, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc. The effect of small size, large active surface and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

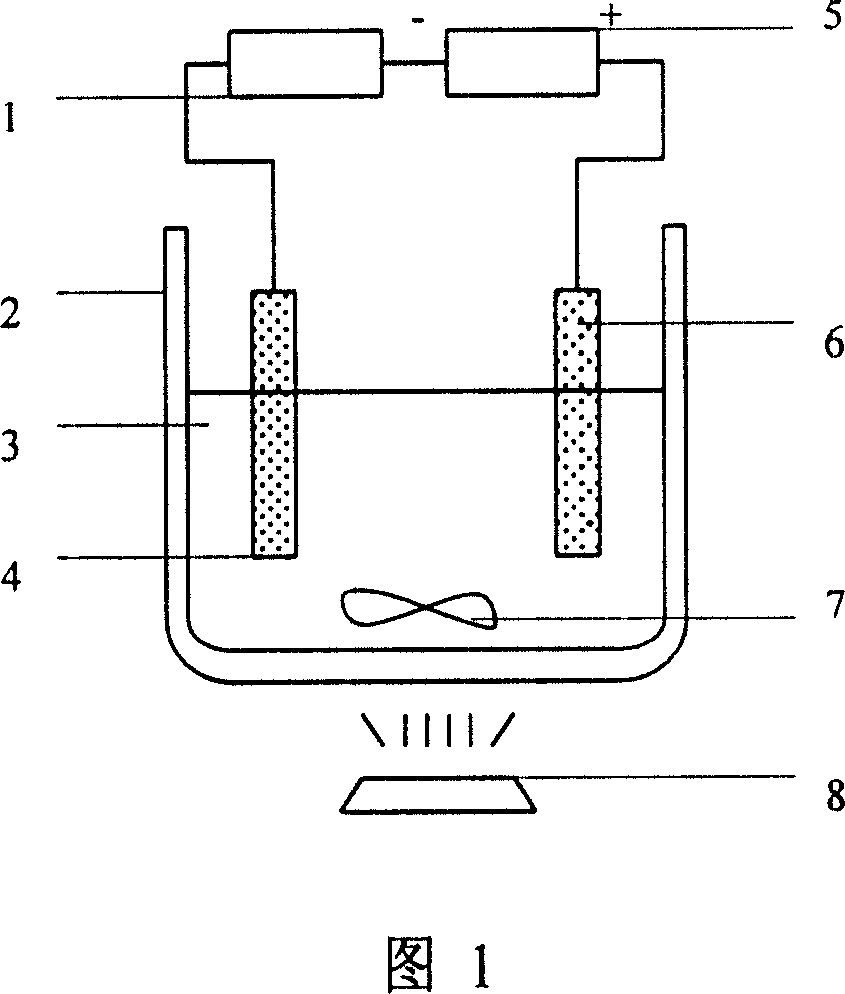

[0030] With reference to accompanying drawing 1 and accompanying drawing 2.

[0031] 4gRhSO 4 Dissolve 2g of sulfuric acid in 1 liter of distilled water, heat to 45°C, turn on the stirrer, and place the inert anode and the 5×5cm 2 The nickel mesh is inserted into the solution, the electronic load is adjusted to keep the current constant at 0.5A, the electroplating time is 30 minutes, it is taken out, rinsed with distilled water, and dried naturally to obtain a rhodium catalyst.

Embodiment 2

[0033] 80gPdCl 2 and 2gNH 4 Dissolve Cl in 1L of distilled water, keep the temperature constant at 42°C, turn on the stirrer, and place the inert anode and the 5×5cm plate to be plated 2 The iron grid is inserted into the solution, the electronic load is adjusted to keep the current constant at 0.5A, the electroplating time is 50 minutes, it is taken out, rinsed with distilled water, and dried naturally to obtain a palladium catalyst.

Embodiment 3

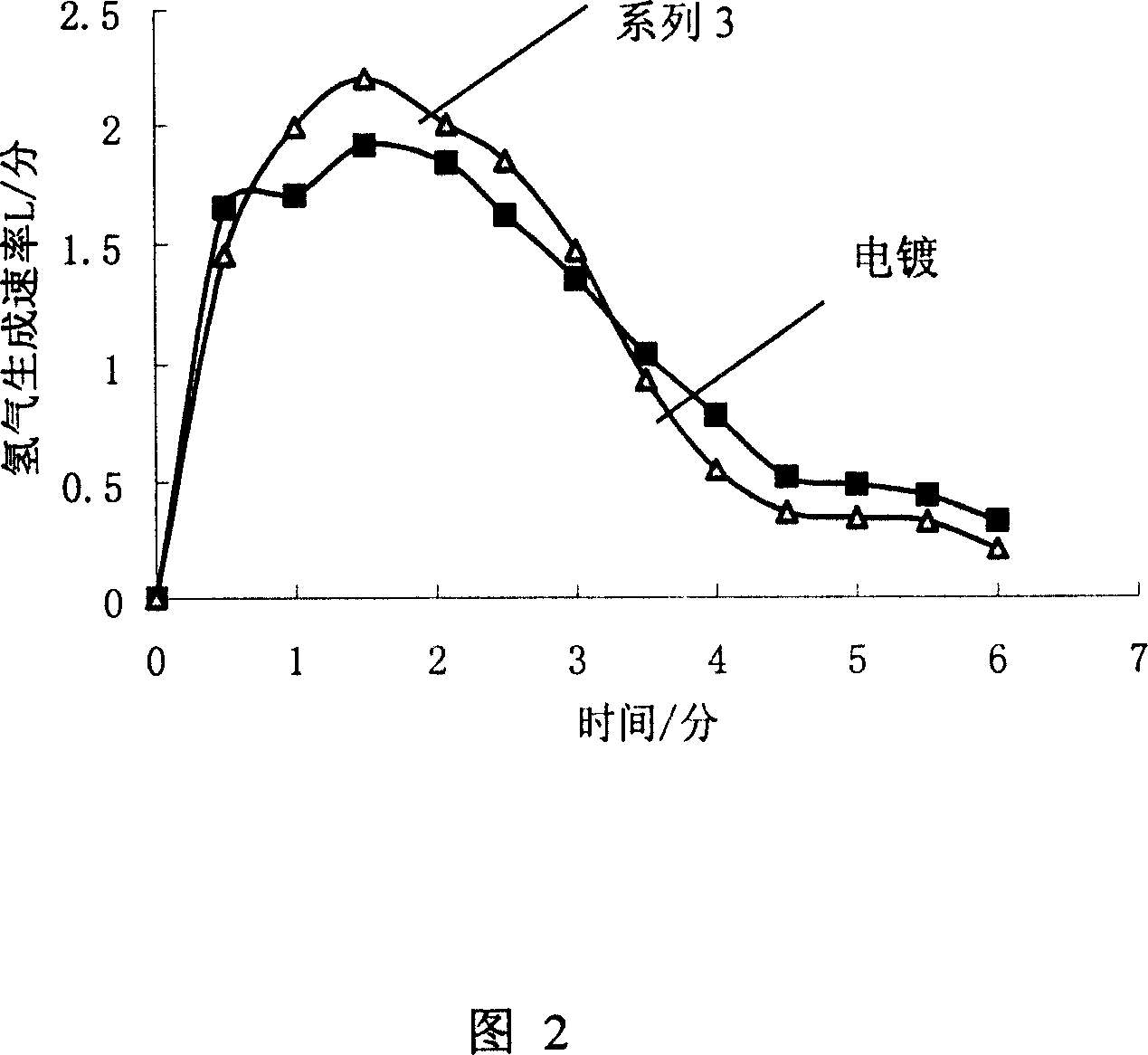

[0035] Weigh 2.5g NaOH dissolved in 15mL distilled water, add 3.5gNaBH 4 , and then add the above-mentioned plated catalyst, 8.2 liters of hydrogen can be obtained within 6 minutes, and the average rate of hydrogen generation is 1.37L / min. After the reaction is completed, there are no catalyst particles falling off in the solution. The hydrogen gas generation rate curve is shown in Figure 2. Series 3 is a powder catalyst generated by direct reduction. It can be seen from the figure that the electroplated catalyst has good activity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com