Cladding type spring rail sleeper

A cladding and elastic technology, applied in the direction of tracks, roads, ballast layers, etc., can solve the problems of three-dimensional impact force and large amplitude, and achieve the effects of reduced rigidity, reduced maintenance and repair workload, and reduced processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

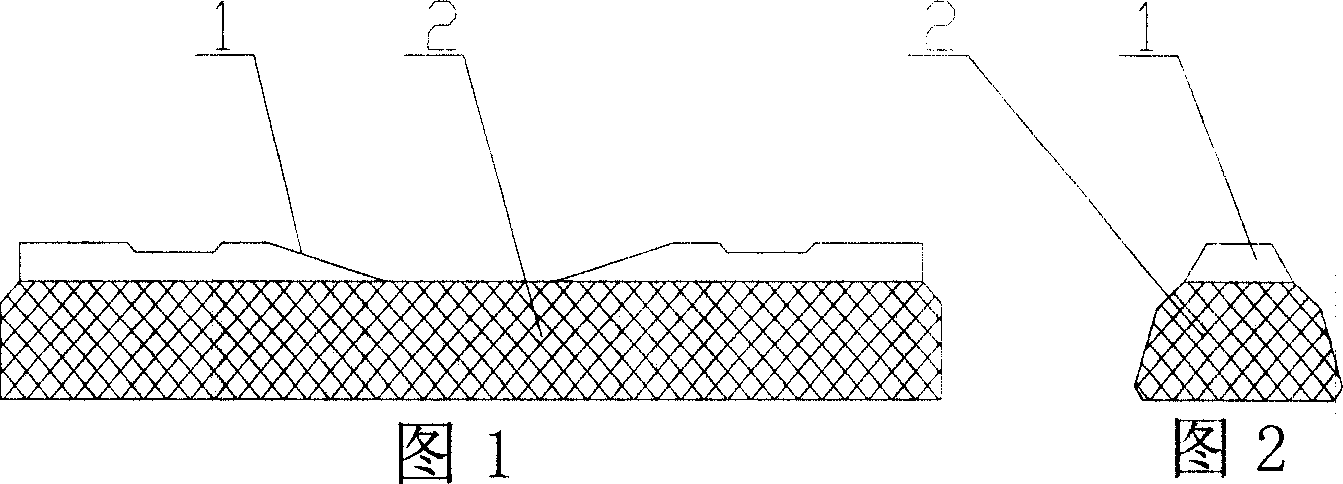

[0079] As shown in Figure 1 and Figure 2, 1 in the figure is a concrete sleeper, and 2 is an elastic covering material. The elastic covering material 2 covers the outer surface of the concrete upper sleeper 1 close to 2 / 3 of the lower part of the sleeper and covers the end surface and the bottom surface. The elastic covering material is made of rubber or rubber-plastic or polyurethane elastomer, which is directly molded on the surface of the sleeper by high-temperature injection, and is fastened to the sleeper by utilizing the material’s cooling shrinkage at low temperature and the slope structure of the concrete sleeper. Anchor and glue for fixing. The sleeper can adopt the concrete sleeper of TB / T2190-2002 standard. This kind of cladding form does not need to change the structural size and section of the sleeper, and has vertical, longitudinal, and horizontal three-dimensional vibration reduction performance, amplitude reduction, and noise reduction performance.

Embodiment 2

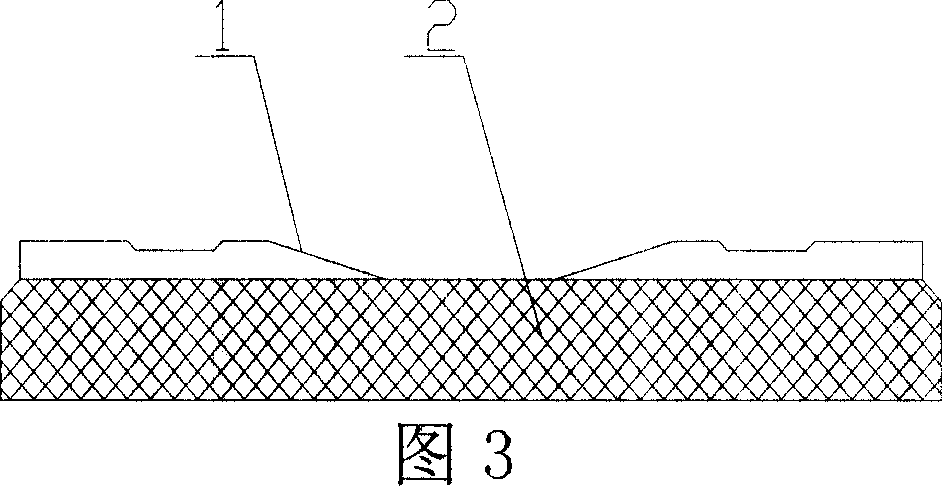

[0081] As shown in Figure 3 and Figure 4, 1 in the figure is a concrete sleeper, and 2 is an elastic covering material. The elastic covering material 2 covers the outer surface of the concrete upper sleeper 1 close to 2 / 3 of the lower part of the sleeper and covers the end surface and the bottom surface. The bottom surface of its coating adopts the form of interval grooves, and the interval grooves are rectangular, so that the elastic covering material 2 can be saved compared with embodiment 1, and the ballast is embedded in it, which also increases the distance between the ballast, the sleeper and the bottom surface covering material. frictional resistance. Others are the same as embodiment 1.

Embodiment 3

[0083] As shown in Figure 5 and Figure 6, 1 in the figure is a concrete sleeper, and 2 is an elastic covering material. The elastic covering material 2 adopts the form of covering the outer surface of the concrete sleeper 1 close to 2 / 3 of the lower part of the sleeper and covering the end surface and the bottom surface. The two sides of its cladding adopt interval form, and interval is rectangle, can save elastic cladding material 2 like this with respect to embodiment 1, simultaneously ballast is embedded in it, has also increased the friction between ballast and sleeper and side cladding material. resistance. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com