Pre-treating process for sewage from thick oil refining

A refinery sewage and pretreatment technology, applied in the direction of flotation water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of unfavorable heavy oil resource recovery, high cost, no Really solve the problem of ultra-heavy oil sewage treatment and other problems, achieve significant social and economic benefits, and realize the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Super-heavy oil refining wastewater pretreatment process flow

[0029]Please refer to Figure 1. Super-heavy oil sewage first enters the regulating water tank 1, as a buffer tank for the sewage to enter the treatment system, providing stable water quality and quantity for the process operation, and completing the recovery of the floating oil and dispersed oil in the sewage and the sedimentation. Removal; the effluent from the regulating water tank 1 and the demulsifier from the demulsifier tank 2 are mixed in the pipeline and then lifted by the pump 3 into the sedimentation degreasing tank 4, at this stage, most of the emulsified oil and dissolved oil in the water body are recovered, and the water is discharged It is introduced into the buffer tank 5; the water in the buffer tank 5 is pressurized by the lift pump 6 at an appropriate flow rate and then sent to the cyclone oil-water separator 7 for oil-water separation (working pressure 0.2-0.6MPa), in the sedimentat...

Embodiment 2

[0034] Example 2 Dissolved air flotation machine

[0035] The dissolved air flotation machine used in the process of Example 1 may be a conventional pressurized dissolved air purification mechanism, or may be a dissolved air flotation device as described in FIG. 2 and FIG. 3.

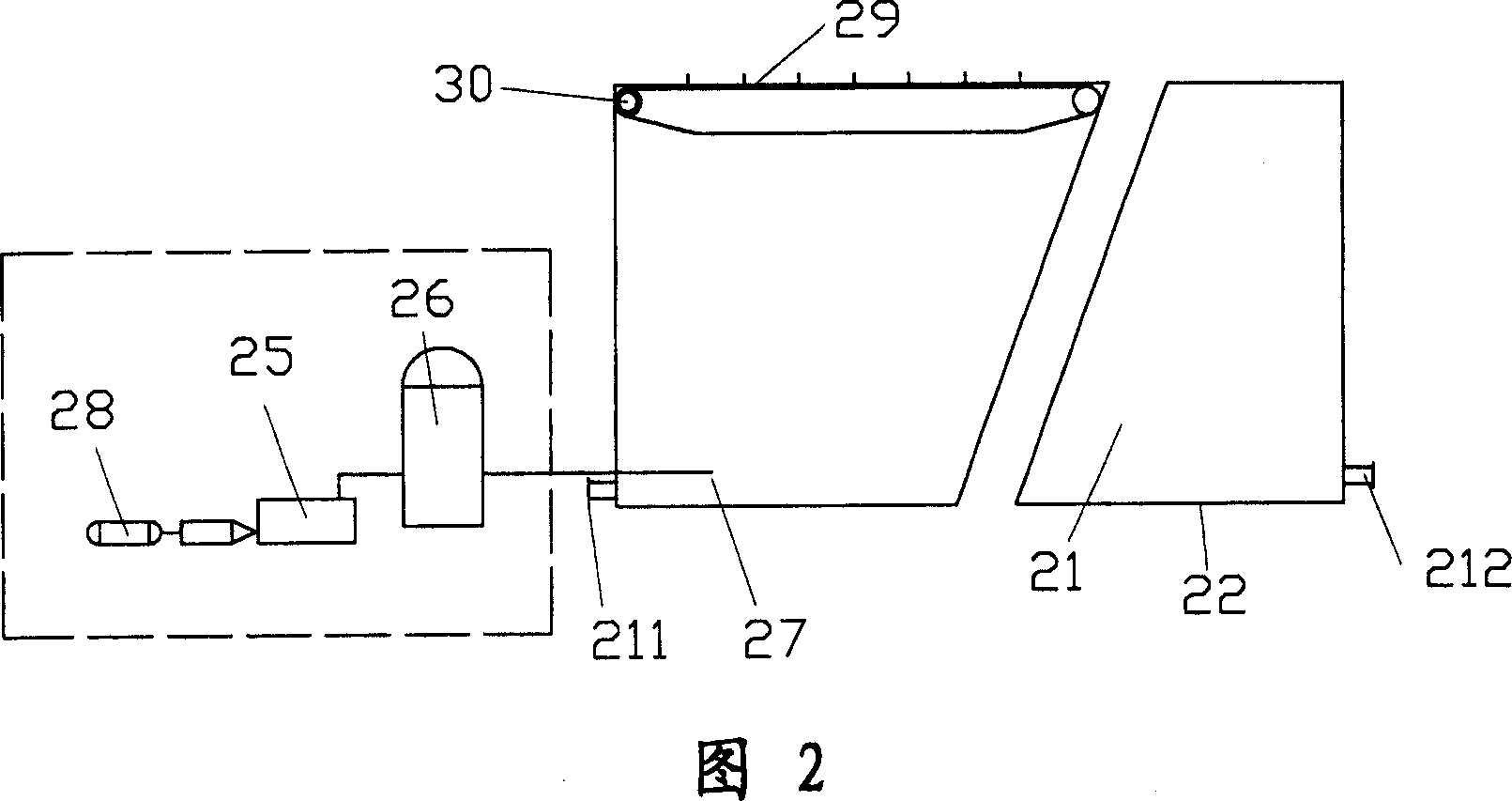

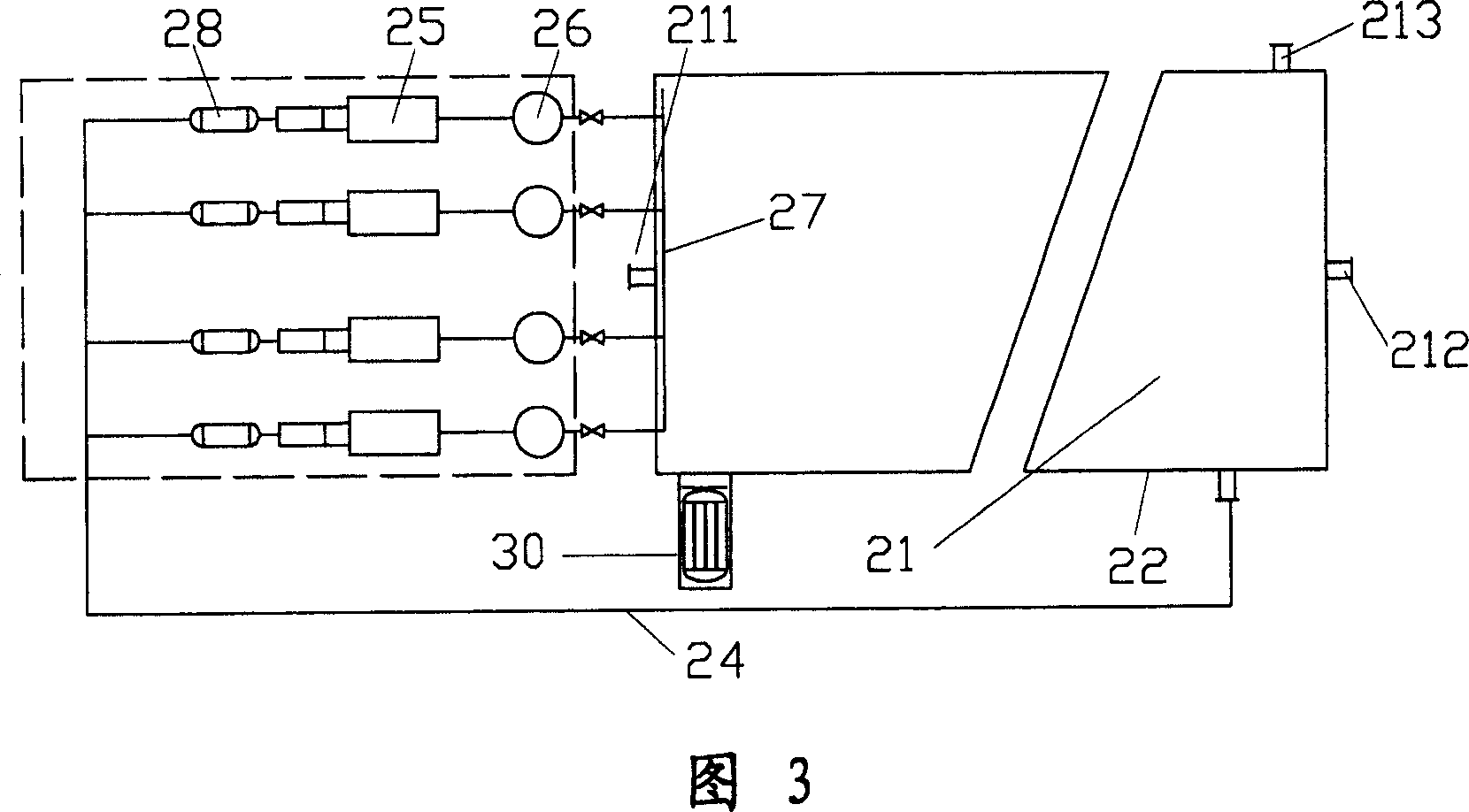

[0036] 2 and 3, the air flotation device of this embodiment mainly includes a flotation tank, a dissolved gas and release system, and a slag scraping system.

[0037] The inlet and outlet ports 211 and 212 of the flotation tank 21 are respectively arranged at appropriate positions on the lower left and right lower sides of the shell 22 (the figure shows the position of the center of the lower part of the side), and the other upper part of the flotation tank 21 is arranged The slag outlet 213, the dissolved gas water outlet of the dissolved gas device (the part shown by the dashed frame in the figure) is connected to the regulating valve and then connected to the flotation water inlet with a pipeline. The si...

Embodiment 3

[0044] Among the pollution sources generated by various installations of PetroChina Liaohe Petrochemical Company, super-heavy oil sewage has the greatest impact on the sewage field, which is also a special case among my country's refining and chemical enterprises. According to the process and operation of Example 1 and Example 2, the ultra-heavy oil wastewater pretreatment process was the first to successfully realize industrial application in Liaohe Petrochemical Branch. The designed processing capacity is 60t / h; the total project investment including process equipment and infrastructure is 7.02 million yuan; the operating cost is 3.05 yuan / ton of sewage, the recovery rate of petroleum is as high as 95%, and the annual efficiency is more than 2 million yuan / year. Achieve the expected operating effect.

[0045] Refer to the description of Example 1 for the specific process operation of the pretreatment of the ultra-heavy oil refining wastewater from PetroChina's Liaohe Oilfield. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com