Bauxite stripping process by Bayer process

A bauxite and Bayer process technology, applied in the field of Bayer process dissolution process of bauxite, can solve the problems of short thermal insulation reaction dissolution time, increased system resistance, large power consumption, etc. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

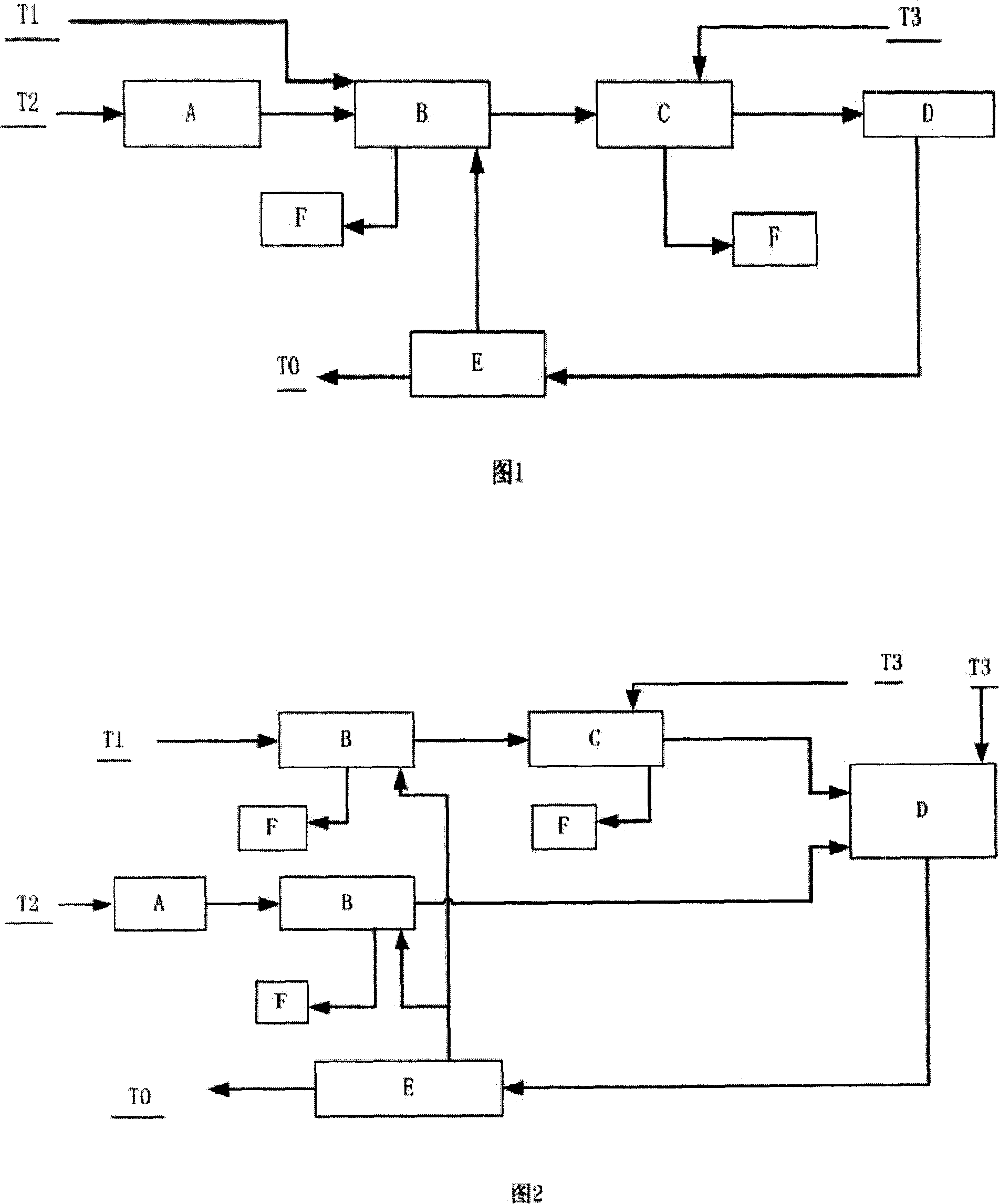

[0033] As shown in Figure 1, the gibbsite-type bauxite is ground with part of the circulating lye and lime to make bauxite slurry T2 with a solid content of 600g / l. The bauxite slurry T2 is indirectly heated to 100°C and then enters the pre-desilication A. Pre-desilicate for 8 hours, and then add the rest of the circulating lye T1 and pump it into the three-stage preheating sleeve heat exchanger B for preheating, and the multi-stage heating sleeve heat exchanger C is heated to the dissolution temperature with the heat source T3, and then heated Afterwards, heat preservation reaction dissolution is carried out in tank-type pressure cooking heat preservation reaction dissolution D, and after dissolution, it enters the third-stage flash evaporation E to flash and cool down. After flash evaporation, the dissolution process is completed to obtain the dissolved ore pulp T0.

[0034] The heat source T3 that provides heat for the above process is saturated steam or molten salt that can...

Embodiment 2

[0038] As shown in Figure 1, the boehmite-type bauxite is ground with part of the circulating lye and lime to make an aluminum ore slurry T2 with a solid content of 300g / l, and the aluminum ore slurry T2 is heated to 100°C through a single-tube heat exchanger Then enter the pre-desilication A for 6 hours pre-desilication, and then add the circulating lye T1 and send it to the ten-stage preheating sleeve heat exchanger B for preheating with a diaphragm pump, and then enter the multi-stage heating sleeve heat exchanger C Heat up to the dissolution temperature with a heat source T3. After heating, carry out heat preservation reaction dissolution in tank pressure cooking heat preservation reaction dissolution D. After dissolution, perform flash evaporation and cooling in ten-stage flash evaporation E to complete the dissolution process to obtain dissolved ore pulp T0.

[0039] The discharge temperature of the final flash evaporation is 125°C. The secondary steam generated by each s...

Embodiment 3

[0043] As shown in Figure 2, diaspore-type bauxite is milled with a small portion of circulating lye and lime to make aluminum ore slurry T2 with a solid content of 900g / L, which is heated to 100°C by a single-tube heat exchanger and then enters the pre-dehydration process. Pre-desiliconization is carried out in silicon A for 6 hours, and the aluminum ore slurry after pre-desiliconization is pumped into the seven-stage preheating sleeve heat exchanger B for preheating to 180°C (pulp flow).

[0044] Most of the circulating lye T1 is sent to the ten-stage preheating casing heat exchanger B by a diaphragm pump for preheating, and then enters the multi-stage heating casing heat exchanger C to be heated to 275°C with a heat source T3 (alkali flow) .

[0045] The above-mentioned pulp flow at 180°C and alkali liquor flow at 275°C are mixed in tank-type pressure cooking heat preservation reaction dissolution D and directly heated to 265°C heat preservation reaction dissolution with su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com