Coarse carbon bisulfide rectifying equipment and method

A carbon disulfide and rectification technology, which is applied in the field of rectification, can solve the problems of unstable quality of carbon disulfide products, difficult control of hydrogen sulfide and sulfur content, and easy formation of hydrates, so as to avoid product waste, avoid environmental pollution, and achieve good separation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

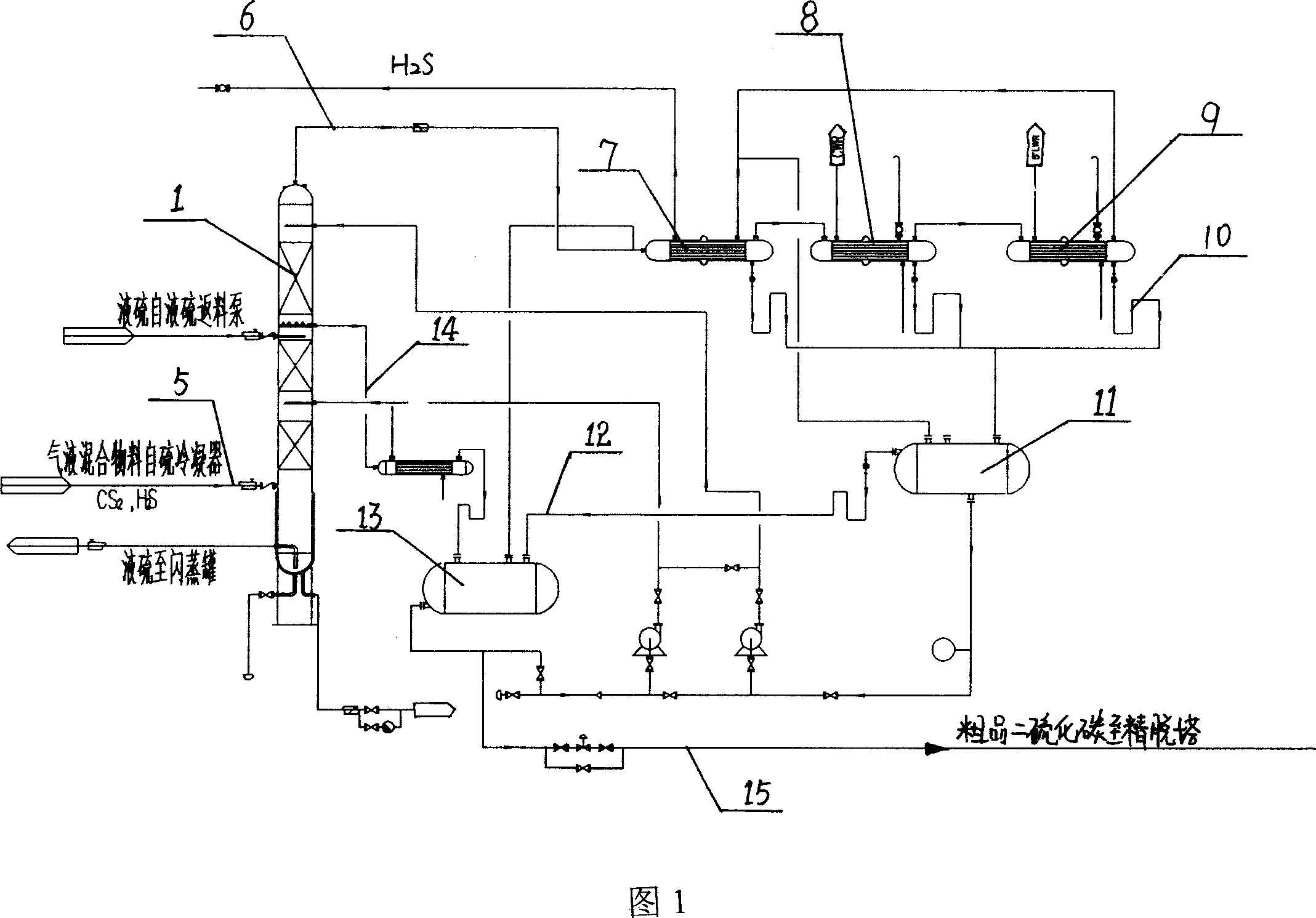

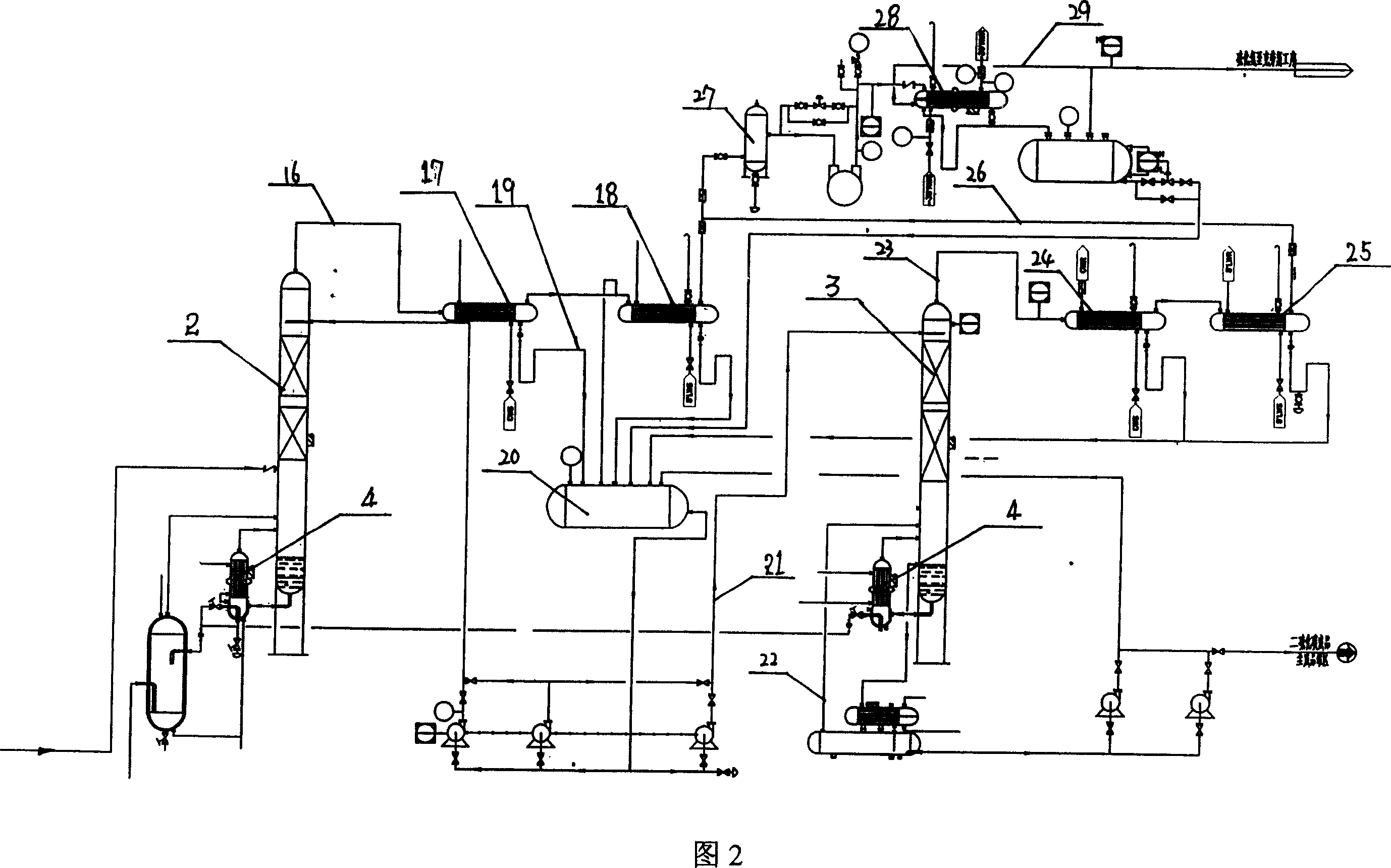

[0015] The rectification equipment for crude carbon disulfide includes a crude stripping tower 1, a fine stripping tower 2 and a finished product tower 3. The rough stripping tower 1 is connected to a sulfur condenser through a gas-liquid mixing pipe 5 and then connected to the reactor. The top of the rough stripping tower 1 passes through Pipeline 6 is connected with condensers 7, 8, and 9 in turn, and liquid carbon disulfide output branch pipes 10 are respectively connected under condensers 7, 8, and 9. Liquid carbon disulfide output branch pipes 10 are connected with mixer 11, and mixer 11 is connected with redistribution through pipeline 12. Connect with device 13, the middle part of coarse stripping tower 1 is connected with the carbon disulfide output pipe 14 that communicates with redistributor 13, and the subdivider 13 below is connected with fine stripping tower 2 by pipeline 15, and fine stripping tower 2 tower tops pass pipeline 16 successively with Condensers 17 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com