Integral gold refining kiln oxidizing roasting process for refractory gold ore

A technology for refractory gold ore and oxidative roasting, applied in the field of precious metal processing, can solve the problems of long process flow, complicated operation and high equipment requirements, and achieve the effect of solving serious environmental pollution, easy control of conditions and large ore processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

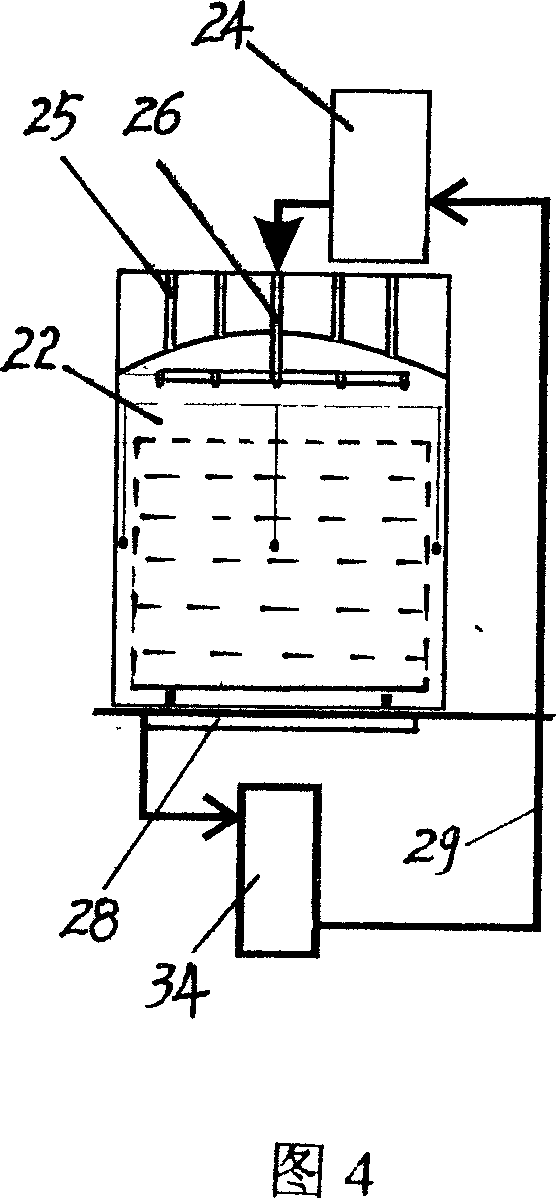

Image

Examples

Embodiment 1

[0033] In a gold mine in Yunnan, more than 90% of the gold is wrapped in pyrite and arsenopyrite in fine granular form. The ore contains S13%, As0.12%, C3%, Sb1%, etc., which is an extremely difficult gold to handle. Mine, pass it through the following process steps;

[0034] A. Grind the above gold ore to 40 mesh;

[0035] B. Add 1% by mass of pulverized coal rib burner to the above-mentioned ground gold ore, so that the carbon content in the mixture is controlled at 4% by mass. After fully mixing, it is made into a block or honeycomb shape. ;

[0036] C. Load the block or honeycomb material into the kiln car, send it to the preheating zone of the oxidation roasting section of the tunnel kiln, and then ignite and roast. The roasting temperature is 700°C and the roasting time is 3 hours;

[0037] D. After the roasted gold ore is cooled in the cooling zone of the oxidation roasting section of the tunnel kiln, it is then sent to the cooling zone between the oxidation roasting sectio...

Embodiment 2

[0044] In a gold mine in Yunnan, more than 90% of the gold is wrapped in pyrite and arsenopyrite in fine granular form. The ore contains S15%, As0.13%, C2%, Sb1%, etc., which is extremely difficult to handle. Mine, pass it through the following process steps;

[0045] A. Grind the above gold ore to 40 mesh;

[0046] B. Add 8% by mass calcium oxide sulfur fixation and arsenic fixation agent to the ground gold ore to make the sulfur and arsenic in the gold ore react with calcium oxide or calcium carbonate to complete the desulfurization and arsenic removal of the gold ore , At the same time, add 1% mass percentage of carbon powder combustion promoter to the ground gold ore, (generally sulfur>8% can be natural), as the fuel for oxidative roasting, after fully mixing, it is made into a block or honeycomb shape ;

[0047] C. Load the block or honeycomb material into the kiln car, send it to the preheating zone of the tunnel kiln oxidation roasting section for drying, and then ignite an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com