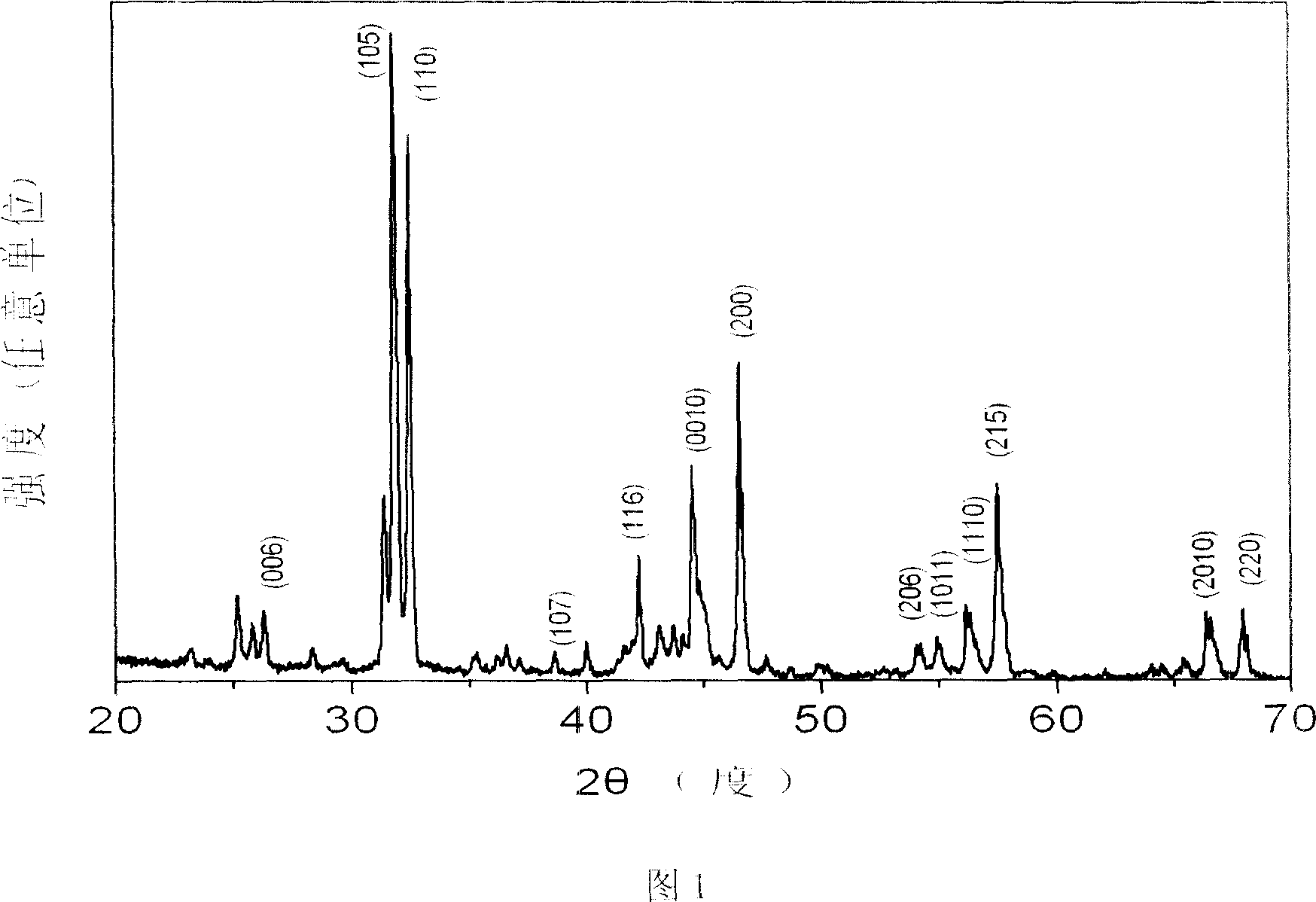

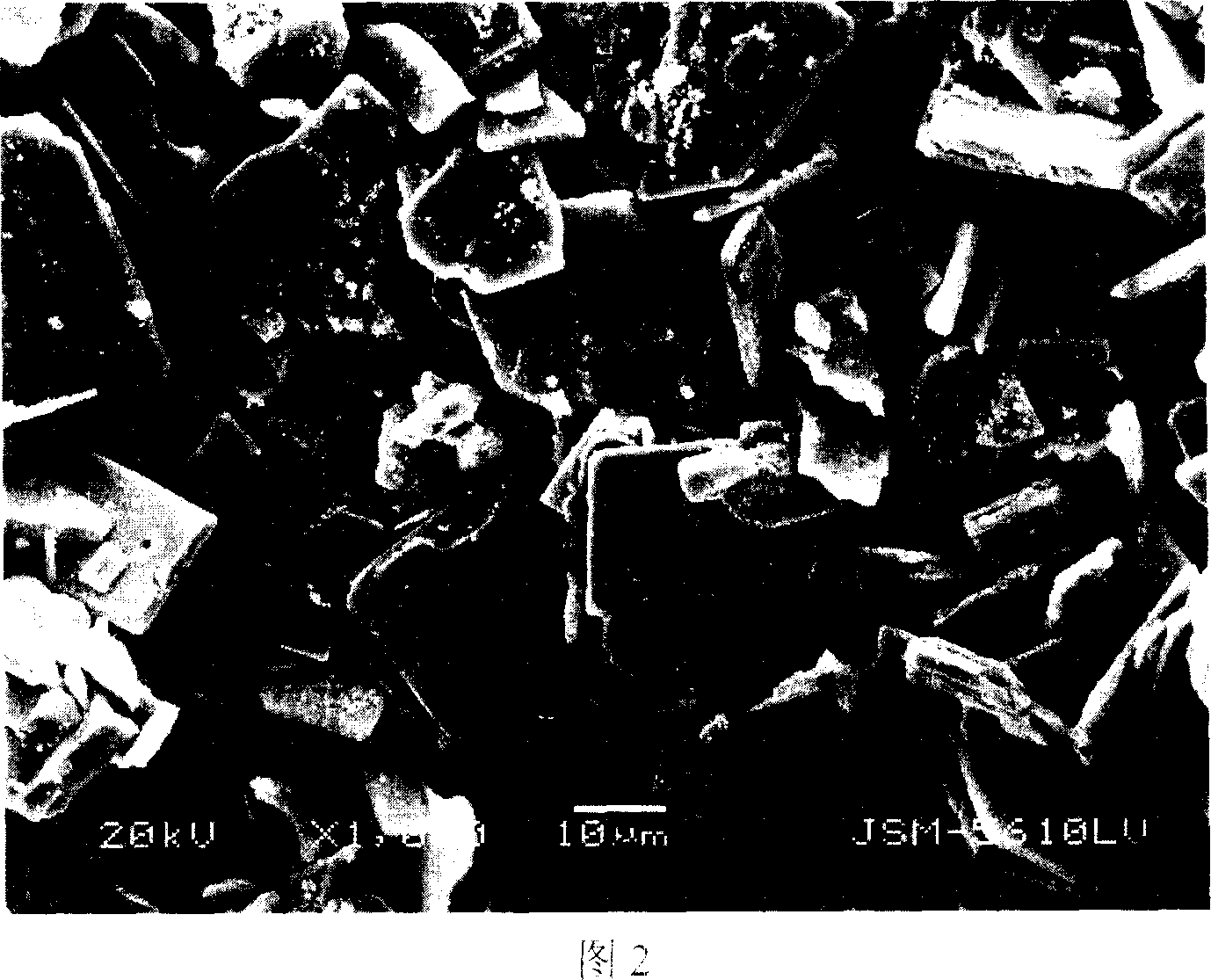

Microwave molten salt process for synthesizing plate Sr3Ti2O7 crystal

A flake crystal and flux technology, applied in the field of artificial crystal growth, can solve the problems of high energy consumption and shortening crystallization time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] SrCO with a purity greater than 99% 3 And TiO with a purity greater than 99% 2 Is the starting reactant, press SrCO 3 : TiO 2 =3:2 stoichiometric ratio for batching; mix and ball mill the prepared starting reaction materials for 6 hours, and then add flux NaCl and KCl. The ratio of the mass of flux to the total mass of the starting reactant is 0.5:1, NaCl The molar ratio of KCl to KCl is 1:1, and then the ball mill is mixed for 6 hours; the dispersant of the two mixed ball mills is anhydrous ethanol; the material after the ball milling is dried in the air at 70℃, and the dried material is After pressing the tablet, put it into the corundum crucible and heat it in a microwave vacuum sintering furnace at 700℃ for 2 hours. The material after the heat treatment is washed repeatedly with deionized water until the water is washed out with AgNO 3 If no chloride ion is detected, perovskite Sr is obtained 3 Ti 2 O 7 Flake crystals.

Embodiment 2

[0020] SrCO with a purity greater than 99% 3 And TiO with a purity greater than 99% 2 Is the starting reactant, press SrCO 3 : TiO 2 =3:2 stoichiometric ratio for batching; mix and ball mill the prepared starting reaction materials for 12 hours, and then add flux NaCl and KCl. The ratio of the mass of flux to the total mass of the starting reactant is 0.5:1, NaCl The molar ratio of KCl and KCl is 1:1, and then the ball mill is mixed for 12 hours; the dispersant of the two mixed ball mills is anhydrous ethanol; the material after the ball milling is dried in the air at 70°C, and the dried material is After pressing the tablet, put it into the corundum crucible and heat it in a microwave vacuum sintering furnace at 700℃ for 2 hours. The material after the heat treatment is washed repeatedly with deionized water until the water is washed with AgNO 3 If no chloride ion is detected, perovskite Sr is obtained 3 Ti 2 O 7 Flake crystals.

Embodiment 3

[0022] SrCO with a purity greater than 99% 3 And TiO with a purity greater than 99% 2 Is the starting reactant, press SrCO 3 : TiO 2 =3:2 stoichiometric ratio for batching; mix and ball mill the prepared starting reaction materials for 6 hours, and then add flux NaCl and KCl. The ratio of the mass of the flux to the total mass of the starting reactant is 1:1, NaCl The molar ratio of KCl and KCl is 1:1, and then the ball mill is mixed for 12 hours; the dispersant of the two mixed ball mills is anhydrous ethanol; the material after the ball milling is dried in the air at 70°C, and the dried material is After pressing the tablet, put it into the corundum crucible and heat it in a microwave vacuum sintering furnace at 700℃ for 2 hours. The material after the heat treatment is washed repeatedly with deionized water until the water is washed with AgNO 3 If no chloride ion is detected, perovskite Sr is obtained 3 Ti 2 O 7 Flake crystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com