Meat product color developing agent

A technology of hair coloring agent and meat products, which is applied in the field of food additives, can solve the problems of fading and poor stability, and achieve the effects of prolonging the shelf life, improving inhibition, and improving color protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Sausage coloring agent formula and processing application method:

[0019] The ratio of raw materials is: carnosine 0.5%, sodium ascorbate 0.25g / kg, potassium sorbate 0.075g / kg, 30% fat meat, 70% lean meat, 20% water, 3.5% salt, 13% sucrose, 4% koji wine . Mince the lean meat and cut the fatty meat into pieces, wash them with hot water at 60°C, mix the meat pieces evenly, add the seasoning prepared by the above formula, and mix well. Soak the casings with clean water, enema, exhaust the needles, tie the ropes in sections, wash them with warm water, hang them on bamboo poles, and bake them in a drying room at a temperature of 50-55°C. When baking, the head needs to be adjusted up and down. After three days of baking, take out the cooling scissors. Saute, weigh, and vacuum pack.

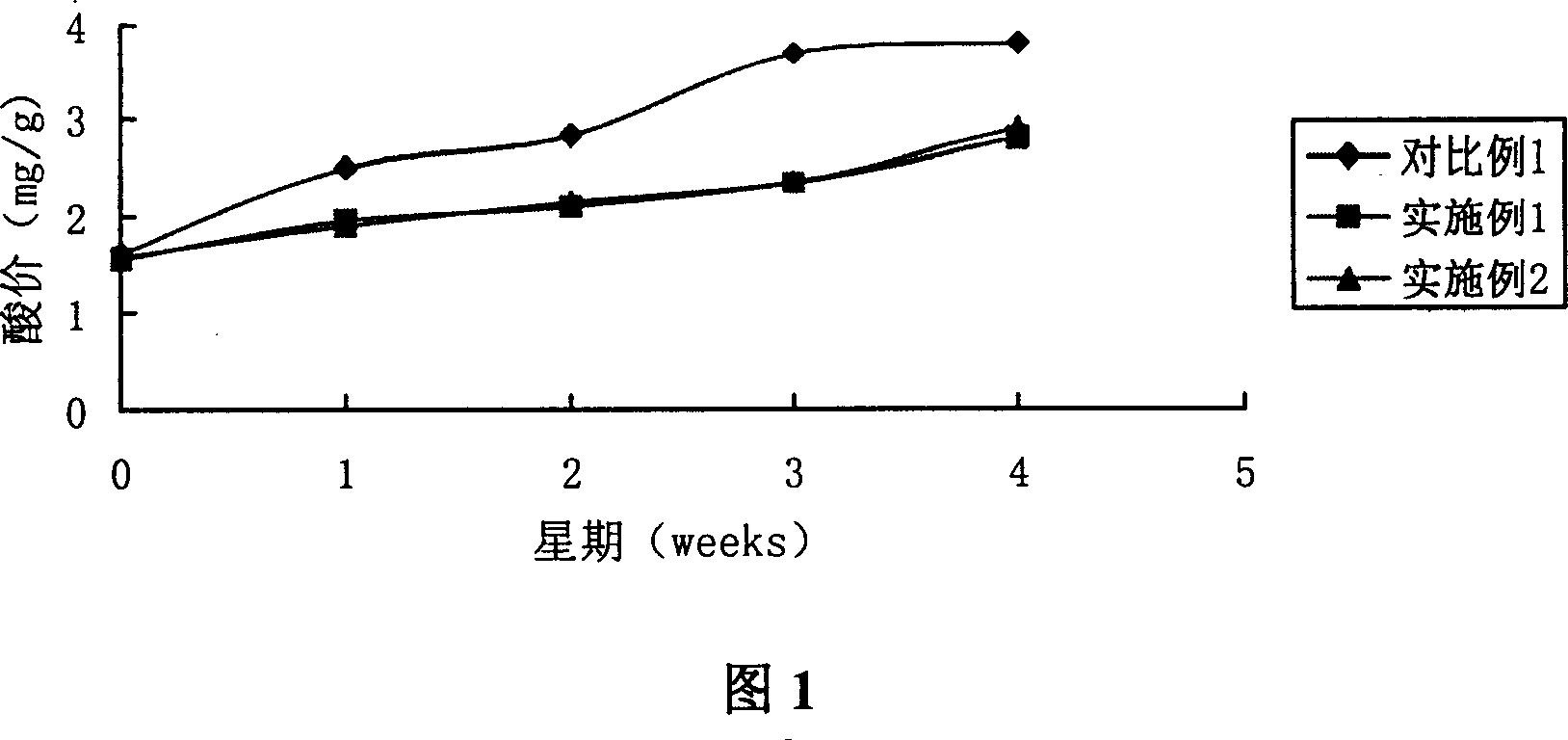

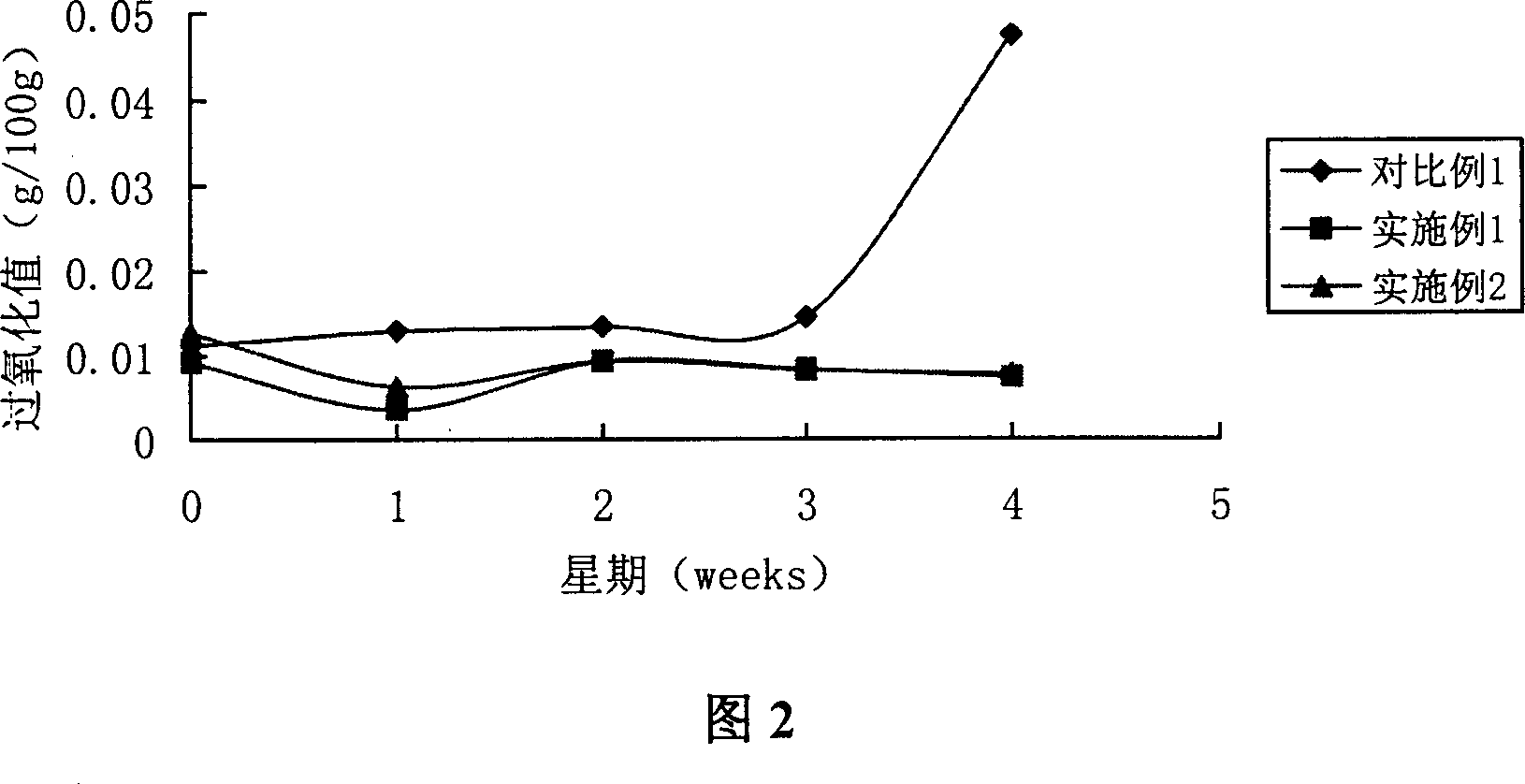

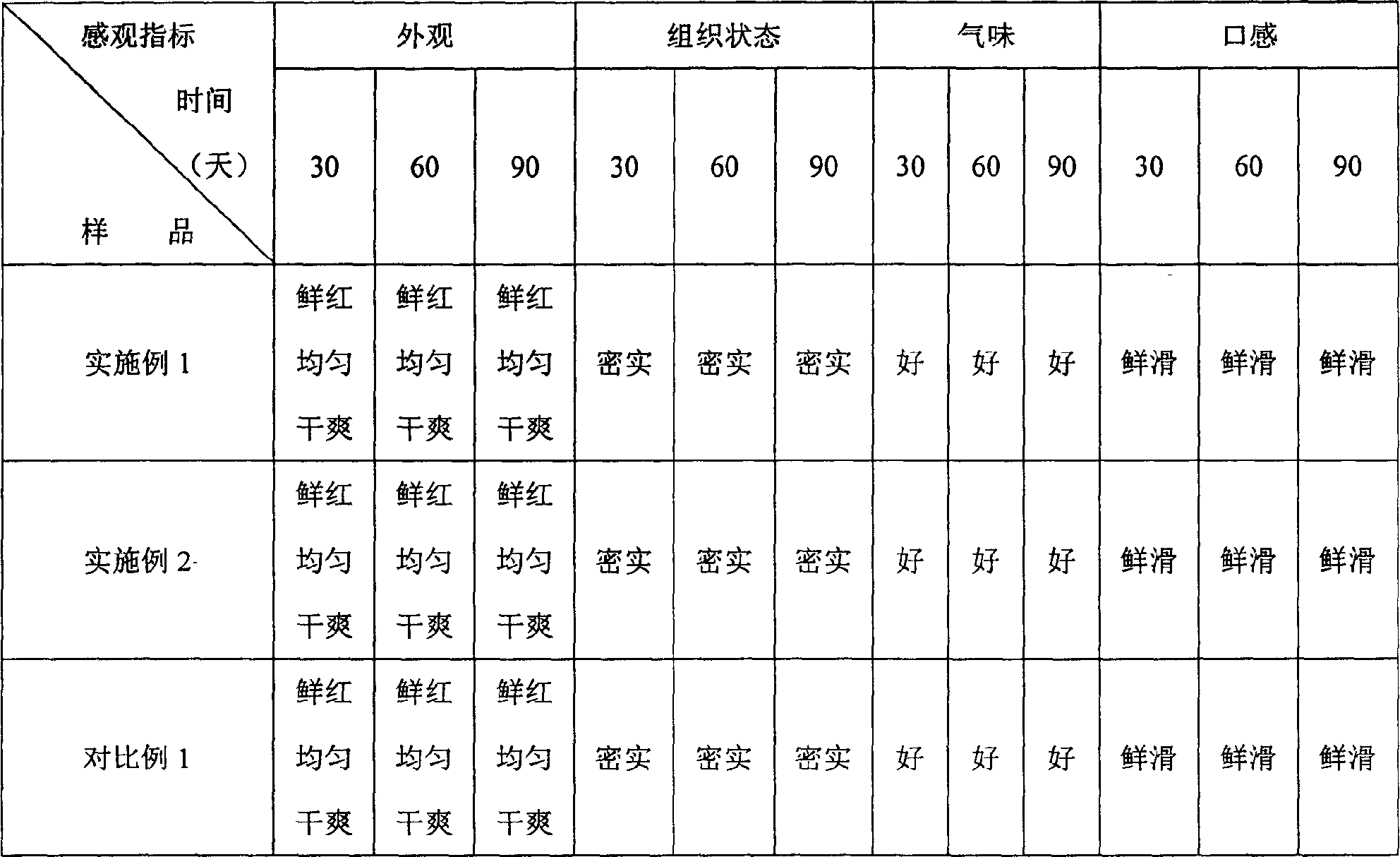

[0020] The appearance, texture, smell and taste of the finished product were evaluated, and the sensory indicators were recorded every 30 days at room temperature. The results are listed in Ta...

Embodiment 2

[0024] Sausage coloring agent formula and processing application method:

[0025] Raw material ratio is: carnosine 0.6%, tea polyphenol 0.15g / kg, Nisin 0.5g / kg, 30% fat meat, 70% lean meat, 20% water, 3.5% salt, 13% sucrose, 4% koji wine. Mince the lean meat and cut the fatty meat into pieces, wash them with hot water at 60°C, mix the meat pieces evenly, add the seasoning prepared by the above formula, and mix well. Soak the casings with clean water, enema, exhaust the needles, tie the ropes in sections, wash them with warm water, hang them on bamboo poles, and bake them in a drying room at a temperature of 50-55°C. When baking, the head needs to be adjusted up and down. After three days of baking, take out the cooling scissors. Saute, weigh, and vacuum pack.

[0026] As described in Example 1, each sensory index of the finished product was recorded, and the results are listed in Table 1.

[0027] As described in Example 1, measure the acid value of the finished product, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com