+/-800kv ultra-high voltage DC synthesized insulator

A technology of composite insulators and UHV DC, applied in the direction of organic insulators, insulators, insulated conductors, etc., can solve problems such as long strings, increased tower body weight and tower head size, and increased project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

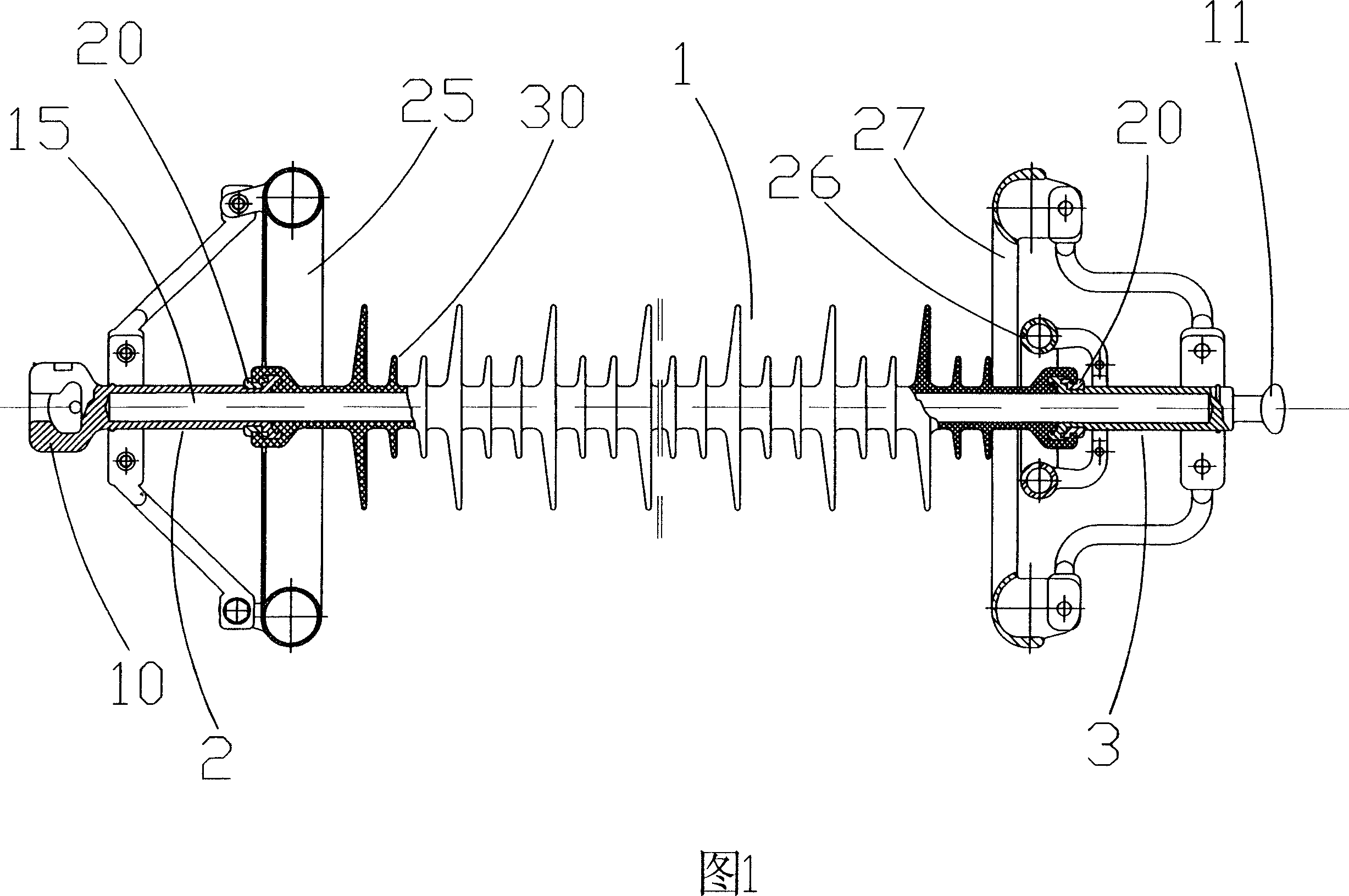

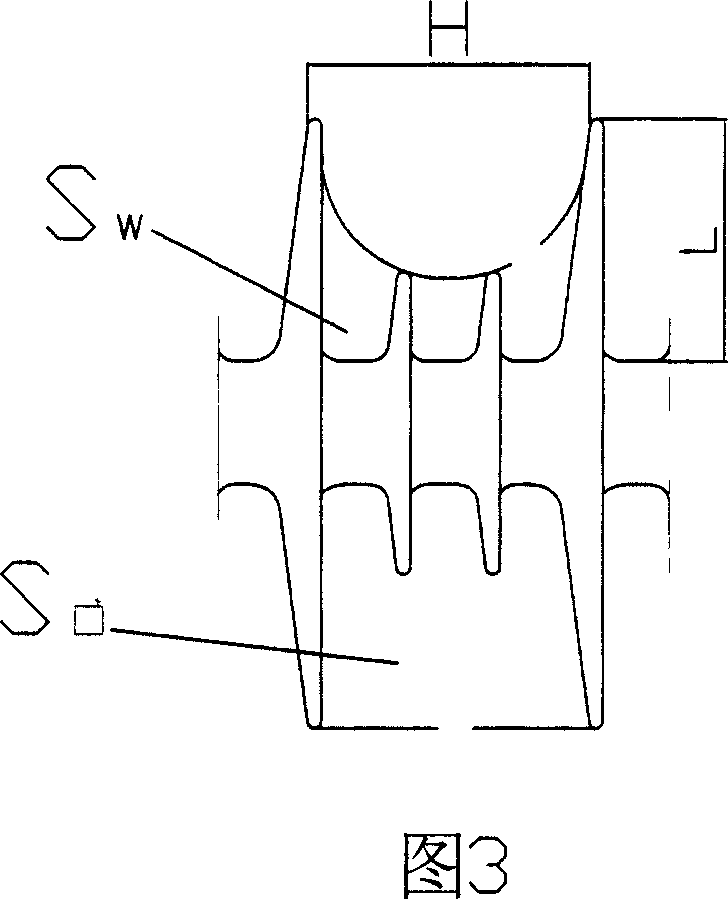

[0033] See accompanying drawings 1 and 2 for the embodiments. The shed shed 30 is based on 110-2 methyl vinyl silicone rubber, adding reinforcing agent fumed silica, flame retardant aluminum hydroxide micropowder, and an appropriate amount of Auxiliary agent and vulcanizing agent, its preferred formula is as follows:

[0034] Serial number Raw material name Weight ratio

[0035] (1) Methyl vinyl silicone rubber 110-2 100

[0036] (2) Fumed silica 35

[0037] (3) Aluminum hydroxide fine powder 125

[0038] (4) Blue masterbatch 1508# 0.07

[0039] (5) Black masterbatch 1800# 0.64

[0040] (6) Zinc dioxide 5

[0041] (7) A-151 1

[0042] (8) Hydroxy silicone oil 5

[0043] (9) H-containing silicone oil 1

[0044] (10) Methyl silicone oil 201 10

[0045] (11) Triethanolamine 0.89

[0046] (12) DCP 1.11

[0047] Among them, the silicone rubber is a combination of several silicone rubbers with different vinyl content, the molecular weight is 600,000 silicone rubber, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com