Extraction technology of avermectin

A technology of abamectin and extraction process, applied in the direction of sugar derivatives, organic chemistry, etc., can solve the problems of unpleasant smell in production environment, bad working environment of employees, low filtration precision of plates and frames, etc. Reduced secondary and tertiary extraction processes, significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

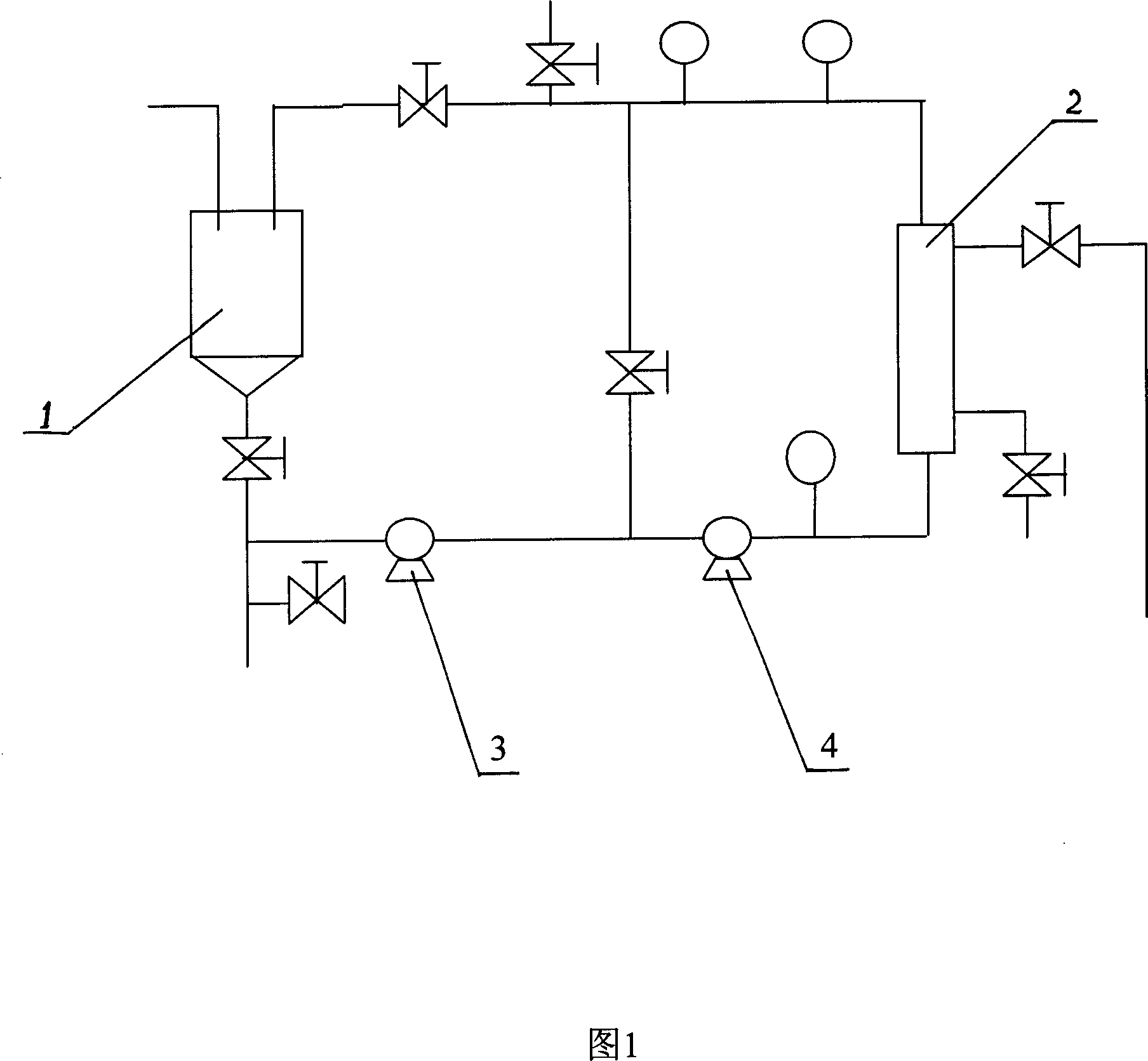

[0021] Embodiment 1: as shown in Figure 1, after abamectin mycelia dry matter is put into extraction tank 1, add organic solvent ethanol with the weight ratio of 1: 5, continue to stir at normal temperature 20~25 ℃ for 3~ After 6 hours, the leachate is made, and then the leachate is filtered through a ceramic membrane filter system 2 with a pore size of 10 μm to 2 nm through a feed pump 3 under a pressure of 0.1 to 0.6 Mpa. The ceramic membrane in the filter membrane system 2 is made of Jiangsu Jiu Wu Hi-Tech Co., Ltd. or German ATECH Technology Development Co., Ltd. uses ceramic filter membranes with a pore size of 10 μm to 2 nm to filter. The filtrate that passes through the filter membrane is sent to the subsequent semi-finished product processing system, and part of the raffinate that does not pass through the filter membrane is returned to the extraction tank. 1. The other part of the raffinate passes through the circulation pump 4 and then passes through the ceramic membr...

Embodiment 2

[0022] Embodiment 2: the difference between this embodiment and embodiment 1 is that organic solvent ethanol is added in a weight ratio of 1: 10; The ratio of raffinate flow rate is 16:1; the inner filter membrane of membrane filtration system 2 adopts stainless steel membrane, and the stainless steel membrane can be stainless steel filter membrane with a pore size of 10 μm to 50 nm produced by Hebei Ruitong Meibang Engineering Co., Ltd. or Kaimembrane Filtration Technology Co., Ltd.

Embodiment 3

[0023] Embodiment 3: the difference between this embodiment and embodiment 1 is that organic solvent ethanol is added in a weight ratio of 1:7; The ratio of raffinate flow rate is 13:1; the inner filter membrane of the filter membrane system 2 adopts hollow fiber membrane, and the hollow fiber membrane can be used by Holland X-FLOW Company, Tianjin Polytechnic University Membrane Engineering Technology Co., Ltd. or Tianjin Tianfang Membrane Separation Project Co., Ltd. produces hollow fiber ultrafiltration membranes with a pore size of 10 μm to 2 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com