Ultra-fine, highly dispersed Pd/C catalyst for direct aminic acid fuel battery and method for making same

A formic acid fuel cell and catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, catalyst carrier, etc., can solve the problems of poor electrocatalytic oxidation activity, low utilization rate of Pd metal, small specific surface area of catalyst, etc., and achieve The effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take 10ml of water, add 23.7mgNaF and 70mgH 3 BO 3 , add 3.13ml 0.04504molL -1 PdCl 2 After ultrasonication for 10 minutes, add 60 mg of activated carbon and continue ultrasonication for 30 minutes to obtain PdCl 2 Adjust the pH of the suspension with activated carbon to 8-9 with ammonia water.

[0033] Take 10ml of water, add 10mg NaBH 4 , the above PdCl 2 The suspension with activated carbon was slowly added dropwise to NaBH 4 In the aqueous solution, continue to sonicate for 1 hour, and stir in a 90°C water bath for 6 hours to make the PdCl 2 with reducing agent NaBH 4 Total response.

[0034] The impurity ions were removed by washing twice with water, and dried at 60° C. under vacuum to prepare a Pd / C powder catalyst with a Pd metal loading of 20%.

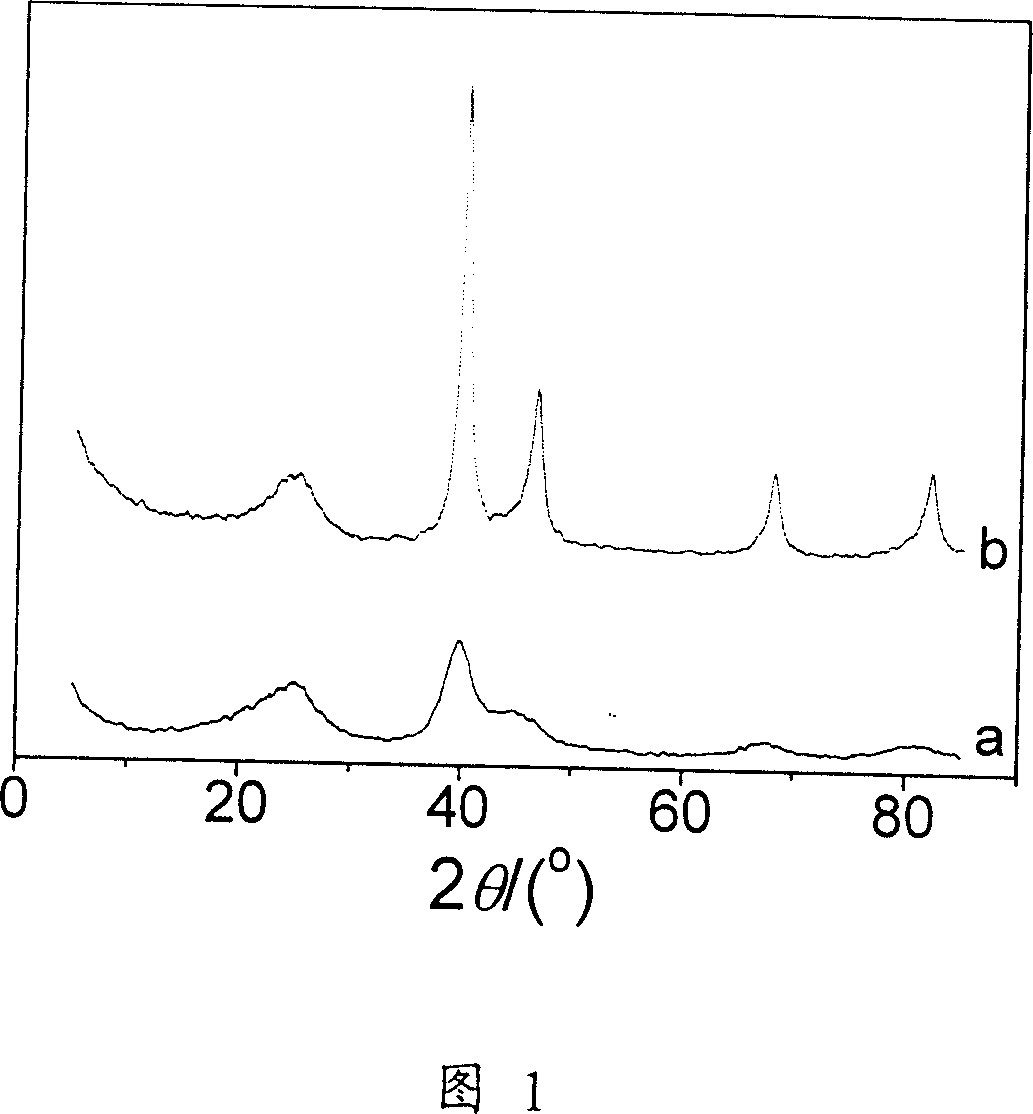

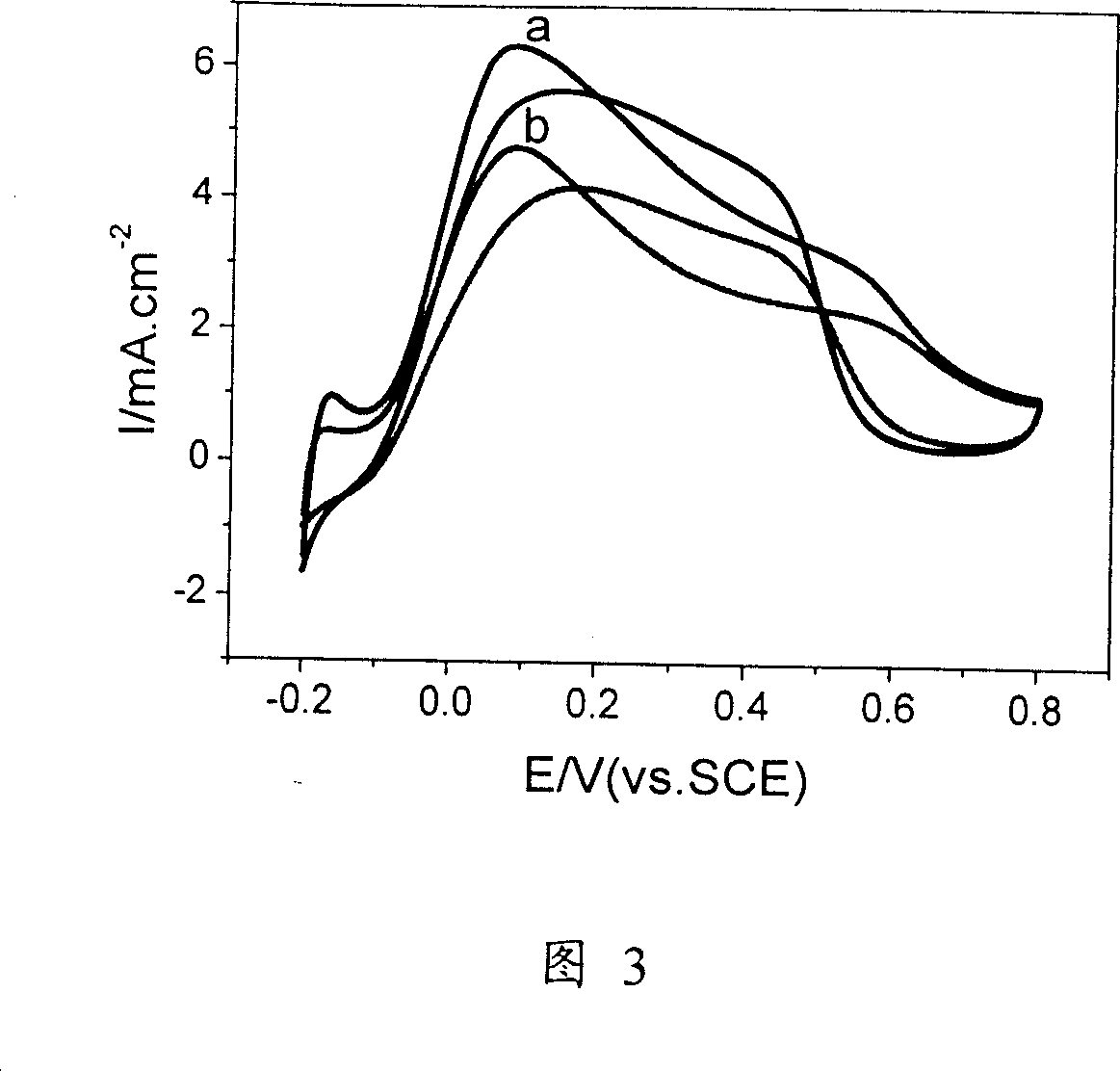

[0035] Figure 1 and Figure 2 show that the average particle size of the Pd / C catalyst obtained in the presence of complexing agent and stabilizer is 3.0nm, and the particles have good dispersion and excellent u...

Embodiment 2

[0038] 10ml water, add 25mgNH 4 F and 225mgH 3 BO 3 , add 5.37ml 0.04504molL -1 PdCl 2 After ultrasonication for 10 minutes, add 60 mg of activated carbon and continue ultrasonication for 30 minutes to obtain PdCl 2 Suspension with activated charcoal.

[0039] Slowly add 10ml 0.1mol.L dropwise under ultrasonic conditions -1 Hydrazine hydrate aqueous solution was ultrasonicated at 80°C for 6 hours.

[0040] After cooling to room temperature, wash with suction and wash with water twice to remove impurity ions.2 The Pd / C powder catalyst with a Pd metal loading of 30% was obtained by drying at 60°C under air protection.

Embodiment 3

[0042] 10ml water, add 44mg KF and 125mg H 3 BO 3 , add 8.37ml 0.04504molL -1 PdCl 2 After ultrasonication for 10 minutes, add 60 mg of activated carbon and continue ultrasonication for 30 minutes to obtain PdCl 2 Suspension with activated charcoal.

[0043] Under ultrasonic conditions, 10 mL of paraformaldehyde aqueous solution containing 10 mg was slowly added, and stirred in a water bath at 90° C. for 6 hours.

[0044] After cooling to room temperature, it was filtered and washed, washed twice with water to remove impurity ions, and dried at 60°C under vacuum to obtain a Pd / C powder catalyst with a Pd metal loading of 40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com