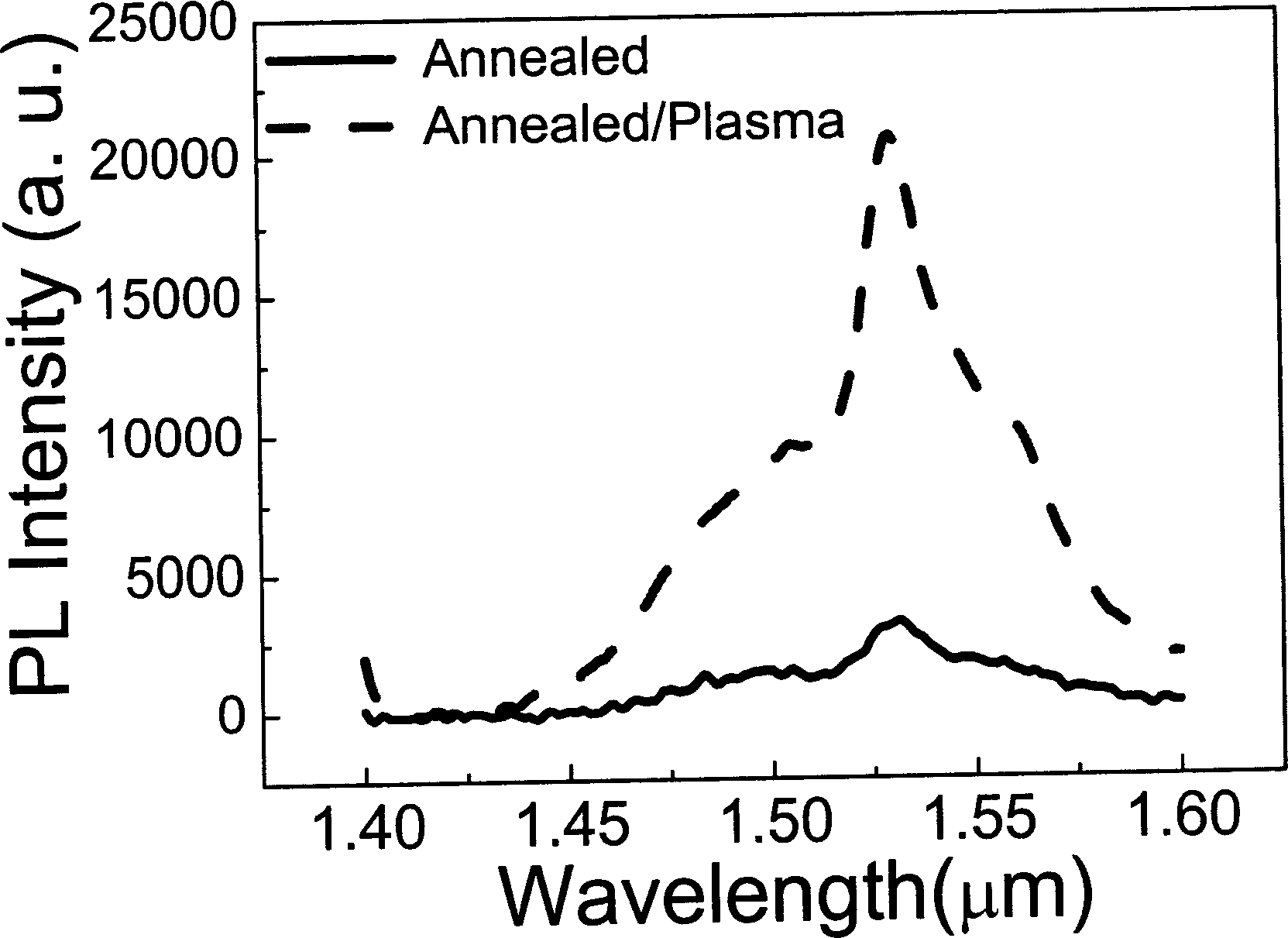

Method for raising radiation of silicone based crystal thin film by use of process of plasma

A plasma and thin film technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of breaking the parity selection rule, changing the spectral wavelength and intensity, etc., to achieve the effect of simple and easy preparation and process compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

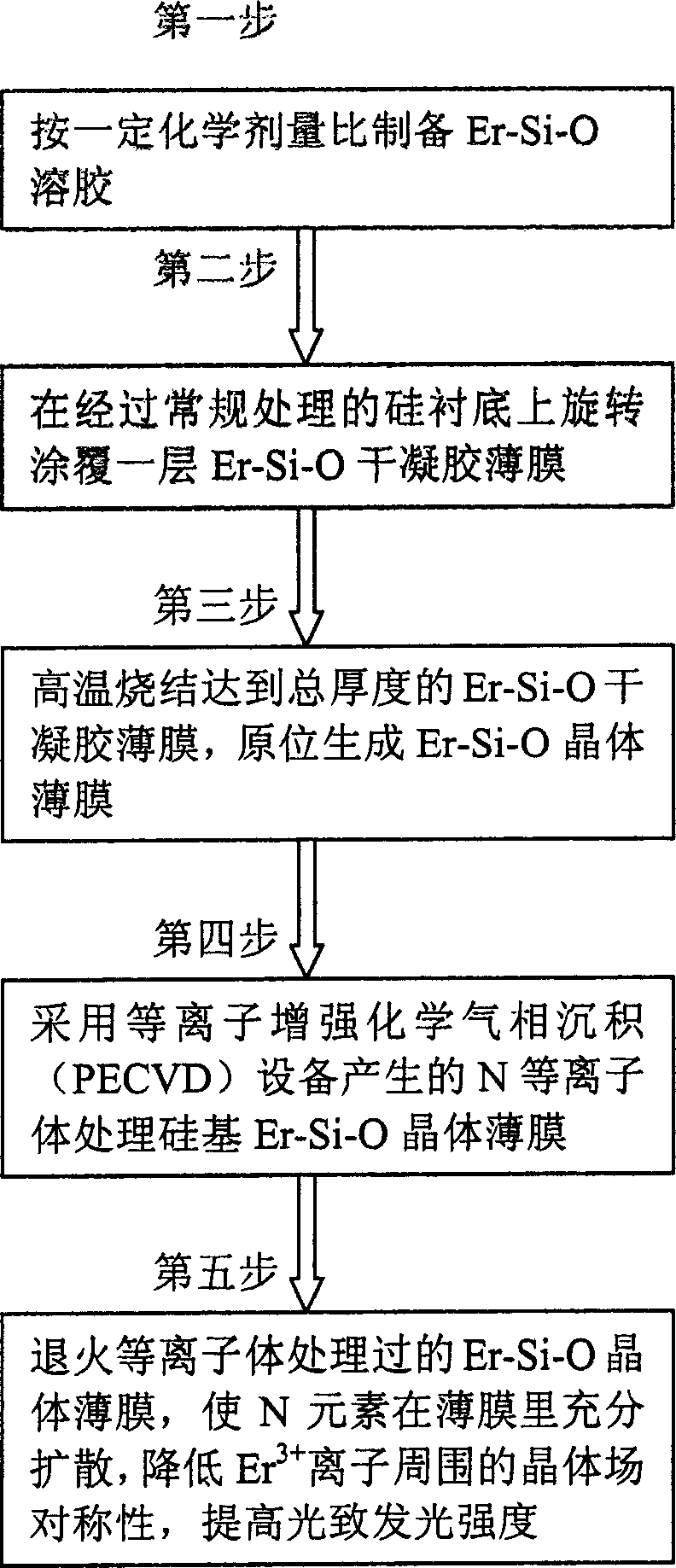

[0025] image 3 A method for improving the luminescence of silicon-based crystal thin films by plasma treatment, the steps are as follows:

[0026] The first step is to prepare Er-Si-O sol according to a certain stoichiometric ratio

[0027] The preparation process is to take 4.5ml of ethyl orthosilicate according to the chemical dosage under the constant temperature condition of 50°C, and then add the mixed solution H containing water and ethanol. 2 O / C 2 h 5 OH 27ml (where H 2 O 4.5ml, C 2 h 5 OH 22.5ml), magnetically stirred for 1 h to mix the solution evenly and hydrolyze TEOS to obtain a network structure. Weigh ErCl according to chemical dosage 3 .6H 2 O powder 11.451g (0.03mol), add 40ml of C 2 h 5 OH, with magnetic stirring for 30min, to make ErCl 3 saturated solution. ErCl 3 Add the saturated solution of TEOS, H 2 O, C 2 h 5 Mix the solution with OH and stir it magnetically for 4 h to make the solution evenly mixed.

[0028] In the second step, a laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com