Outer heat preservation system of composite decorative board of rigid polyurethane for pouring in site, and construction technique

A rigid polyurethane and cast-in-place technology, which is applied in thermal insulation, building components, covering/lining, etc., can solve the problem of affecting the thermal performance and safe use of external wall insulation, product quality and assembly can not achieve standardized management, building exterior Problems such as cracking and falling off of the external insulation layer of the wall achieve the effect of simple standardization of engineering quality control technology, shortening the construction period, and saving engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

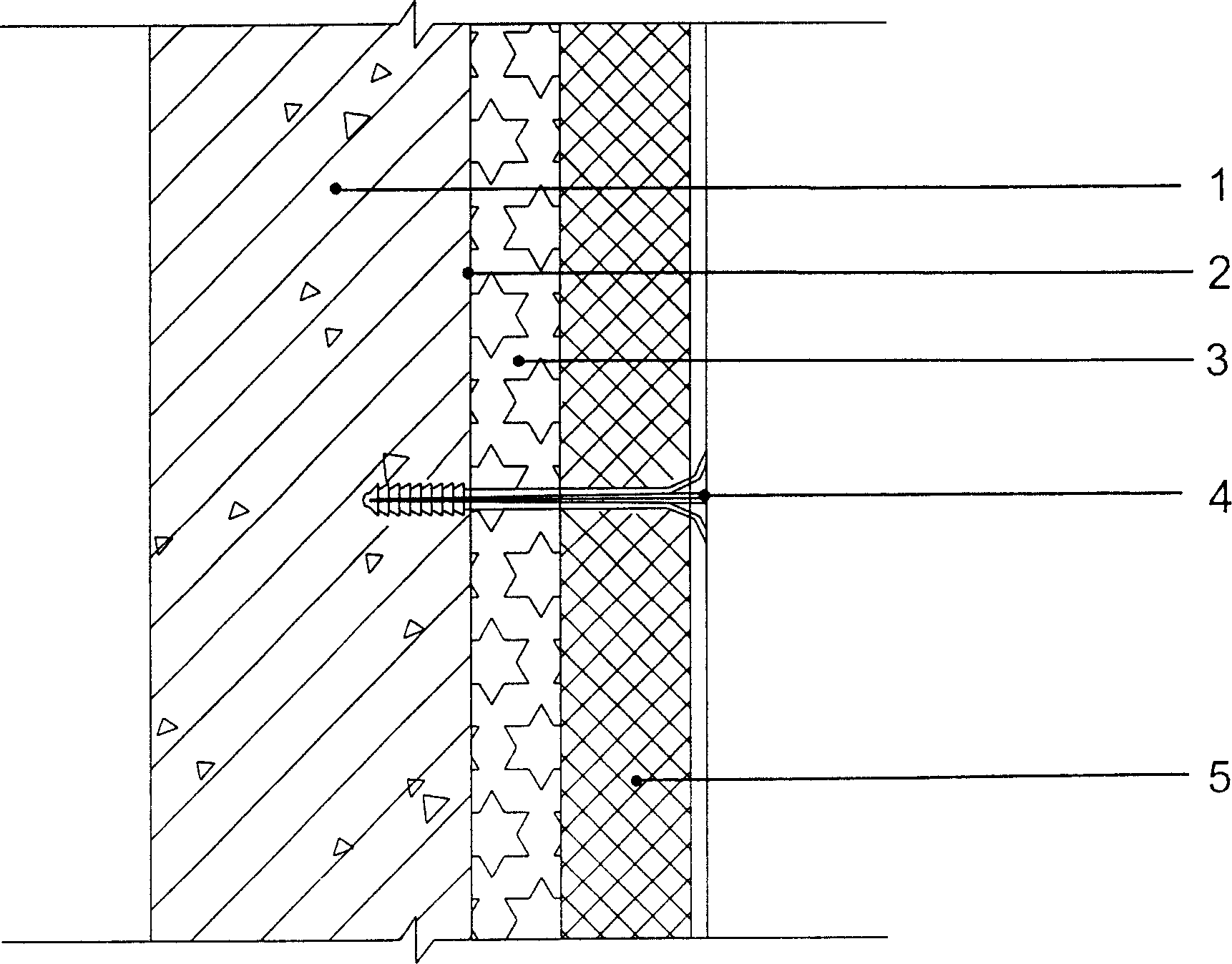

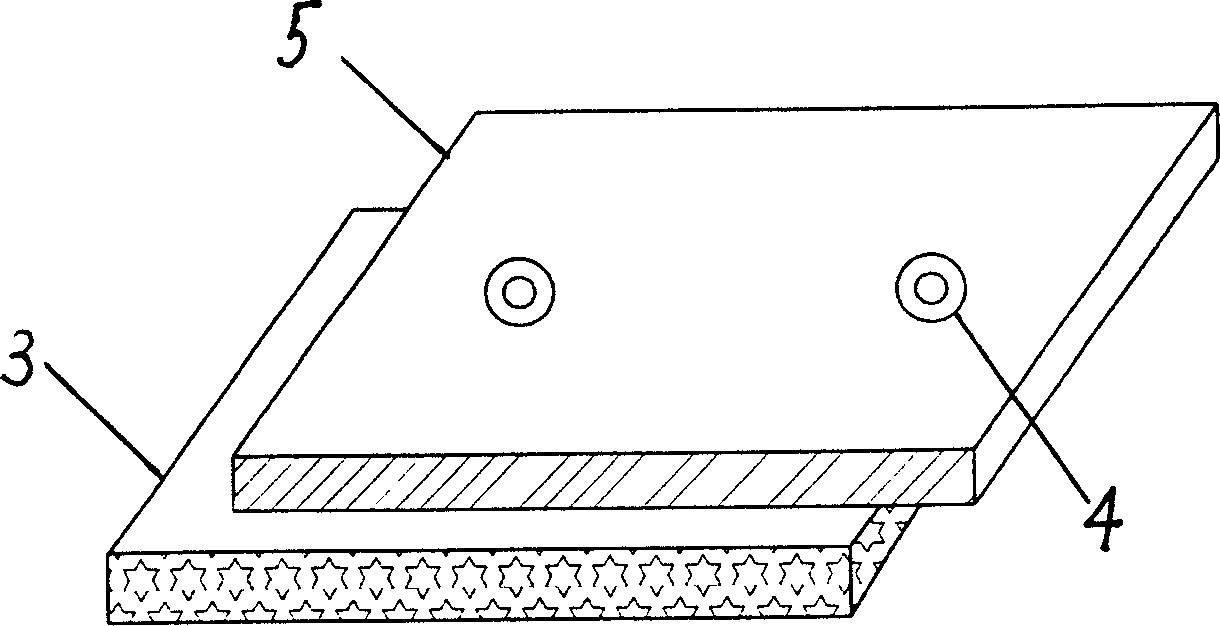

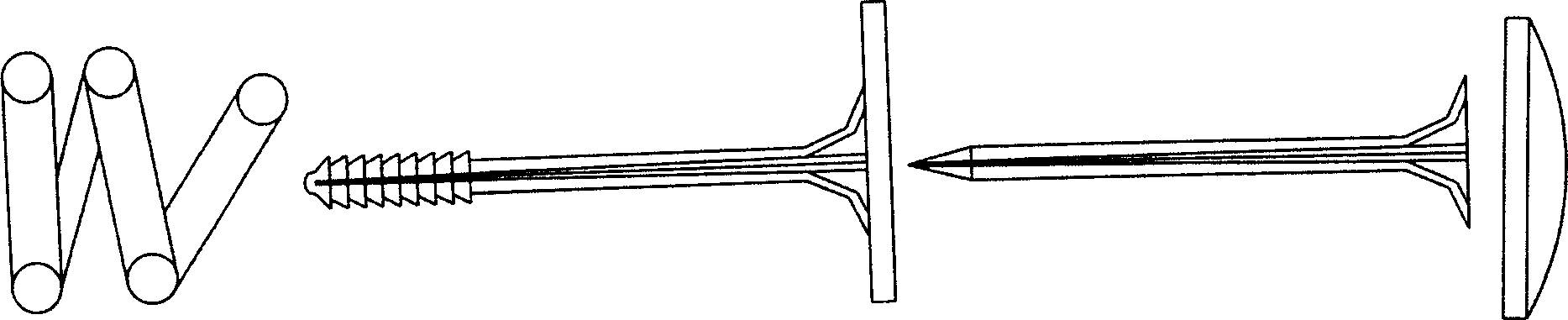

[0016] The structure disclosed in the above drawings is a structure of an embodiment of the present invention. In the figure, 1 is the base layer of the exterior wall of the building that does not need to be leveled; 2 is the interface layer; 3 is the cast-in-place rigid polyurethane adhesive insulation layer; 4 is the invisible plastic expansion anchor; 5 is the dislocation-shaped composite decorative board.

[0017] With reference to the drawings, the external thermal insulation system of the present invention for the cast-in-place rigid polyurethane composite decorative panel includes a base layer 1, an interface layer 2, a field-cast rigid polyurethane bonding thermal insulation layer 3; an invisible plastic expansion anchor is used on the outside of the bonded thermal insulation layer 3 The bolt 4 and the three-dimensional positioning method are provided with a dislocation-shaped thermal insulation decorative board 5, and finally the dislocation-shaped thermal insulation deco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com