Super fine composite terylene fibers storing energy through phase change, and preparation method

A phase change energy storage, polyester fiber technology, applied in fiber chemical characteristics, chemical instruments and methods, rayon manufacturing and other directions, to achieve large specific surface area, excellent mechanical properties and temperature regulation performance, good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

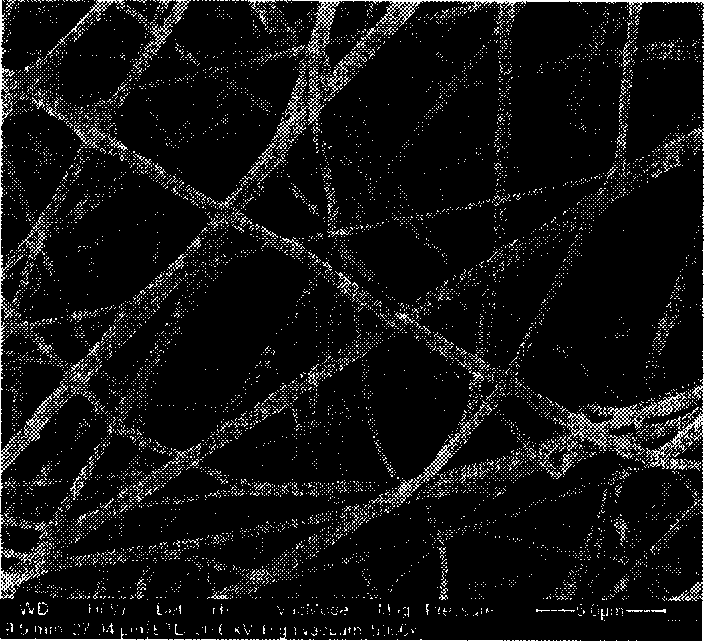

Image

Examples

Embodiment 1

[0026] First, the polyester staple fiber and trifluoroacetic acid are mixed in a mass ratio of 1:5, and then the phase change material stearic acid is added, and the phase change material accounts for 25% of the total mass of the phase change material and the polyester. A uniform mixture is obtained after mechanical stirring Solution; Then the mixed solution is subjected to high-voltage electrostatic field spinning under the conditions of an external environment temperature of 25°C, a relative humidity of 85%, an electrostatic field spinning voltage of 15KV, and a distance between the spinneret and the collecting plate of 10cm, That is to say, the mixed solution is put into a syringe with a spinneret, and the syringe is pushed by the injection pump to make the mixed solution reach the spinneret at a constant rate of injection flow rate of 1 mL / h, and then electrospinning is performed, and the spun is collected by a collecting plate The ultra-fine fibers of the cellulose are vacuum...

Embodiment 2

[0029] First, mix the polyester staple fiber and trifluoroacetic acid at a mass ratio of 1:5, then add the phase change material butanediol distearate, and make the phase change material account for 10% of the total mass of the phase change material and the polyester, and mechanically stir Then a uniform mixed solution is obtained; then the mixed solution is subjected to high pressure under the conditions of an external environment temperature of 22°C, a relative humidity of 65%, an electrostatic field spinning voltage of 20KV, and a distance between the spinneret and the collecting plate of 15cm Electrostatic field spinning is to load the mixed solution into a syringe with a spinneret, and push the syringe through the injection pump to make the mixed solution reach the spinneret at a constant speed with an injection flow rate of 0.2mL / h, and then perform electrospinning. The spun superfine fibers are collected with a collecting plate, and then the residual trifluoroacetic acid is...

Embodiment 3

[0032] First, the polyester staple fiber and trifluoroacetic acid are mixed in a mass ratio of 1:5, and then the phase change material hexanediol distearate is added, and the phase change material accounts for 48% of the total mass of the phase change material and the polyester. Then a uniform mixed solution is obtained; then the mixed solution is subjected to high pressure under the conditions of an external environment temperature of 21°C, a relative humidity of 45%, an electrostatic field spinning voltage of 22KV, and a distance between the spinneret and the collecting plate of 13cm Electrostatic field spinning is to load the mixed solution into a syringe with a spinneret, push the syringe through the injection pump to make the mixed solution reach the spinneret at a constant speed with an injection flow rate of 15mL / h, and then perform electrospinning and use The collecting plate collects the spun ultrafine fibers, and then vacuum drying is used to remove the residual trifluor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com