Protective slag for ultralow carbon steel continuous casting

A technology for continuous casting of mold slag and ultra-low carbon steel, which is applied in the field of mold slag and can solve the problems of hindering mold slag and increasing the viscosity of mold slag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

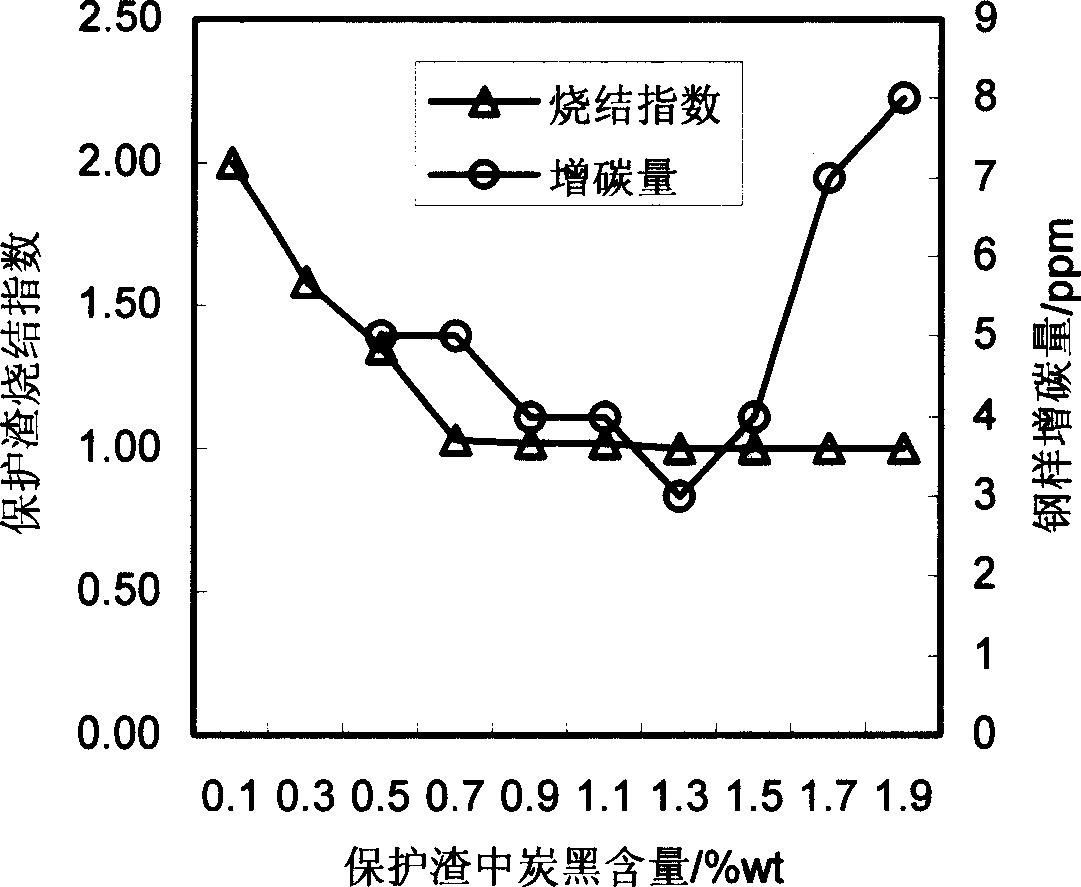

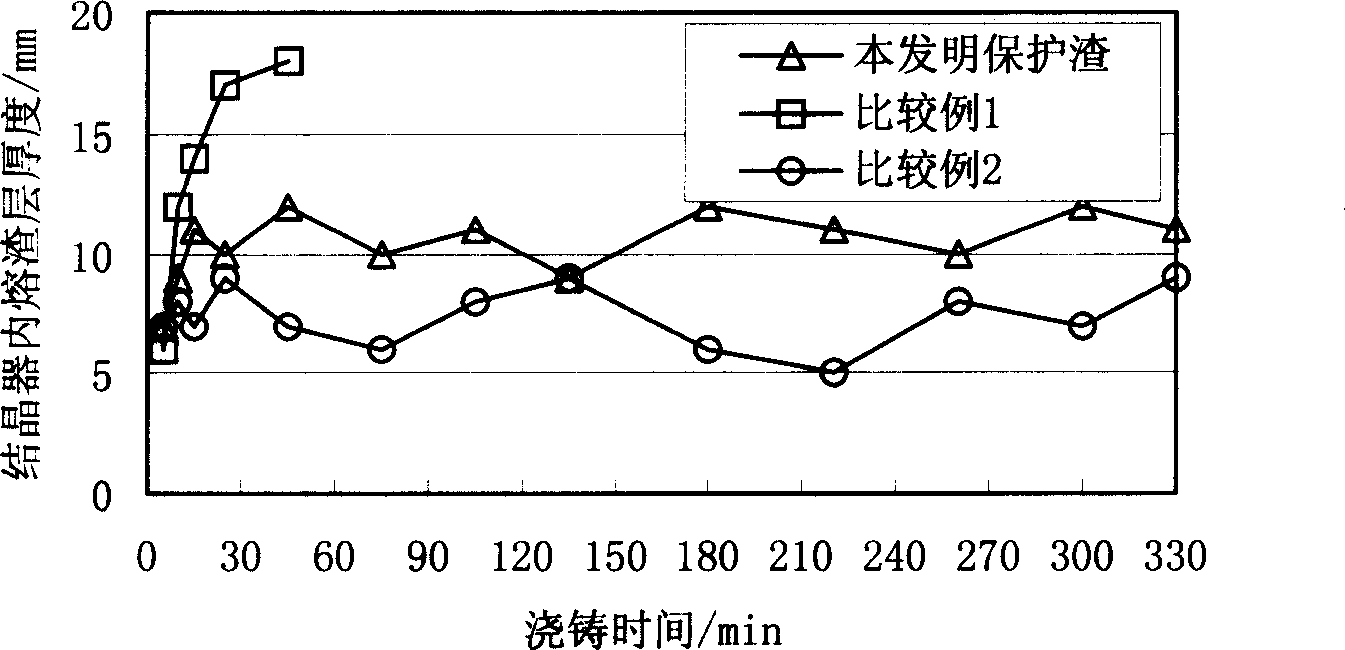

[0017] An ultra-low carbon steel continuous casting mold flux. The components (% by weight) of the mold flux are: 0.5-1.6 carbonaceous material, 2-8 metal melting rate regulator, 2-7 MgO, 6-12 Na 2 O, F from 2 to 8 - , Al of 2 to 7 2 o 3 , 3~8 MnO, 1~3 Fe 2 o 3 , and the rest are CaO and SiO 2 ; Among them, CaO / SiO 2 0.75 to 1.05.

[0018] In the mold flux of the present invention, CaO and SiO 2 As the base material, the basicity of mold flux is controlled by their ratio.

[0019] When casting ultra-low carbon electrical steel with high [Si] content, due to the weak heat transfer capacity of the slab shell, in order to avoid steel breakout accidents, the alkalinity of mold slag CaO / SiO 2 Taking 0.75~0.85 can ensure that the slag film is a glass body and has good lubricating properties for the casting slab;

[0020] When casting [Ti] or [Nb]-free stamping steel, the basicity CaO / SiO 2 0.85-1.05, which is beneficial for the mold slag to absorb the Al at the mold steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com