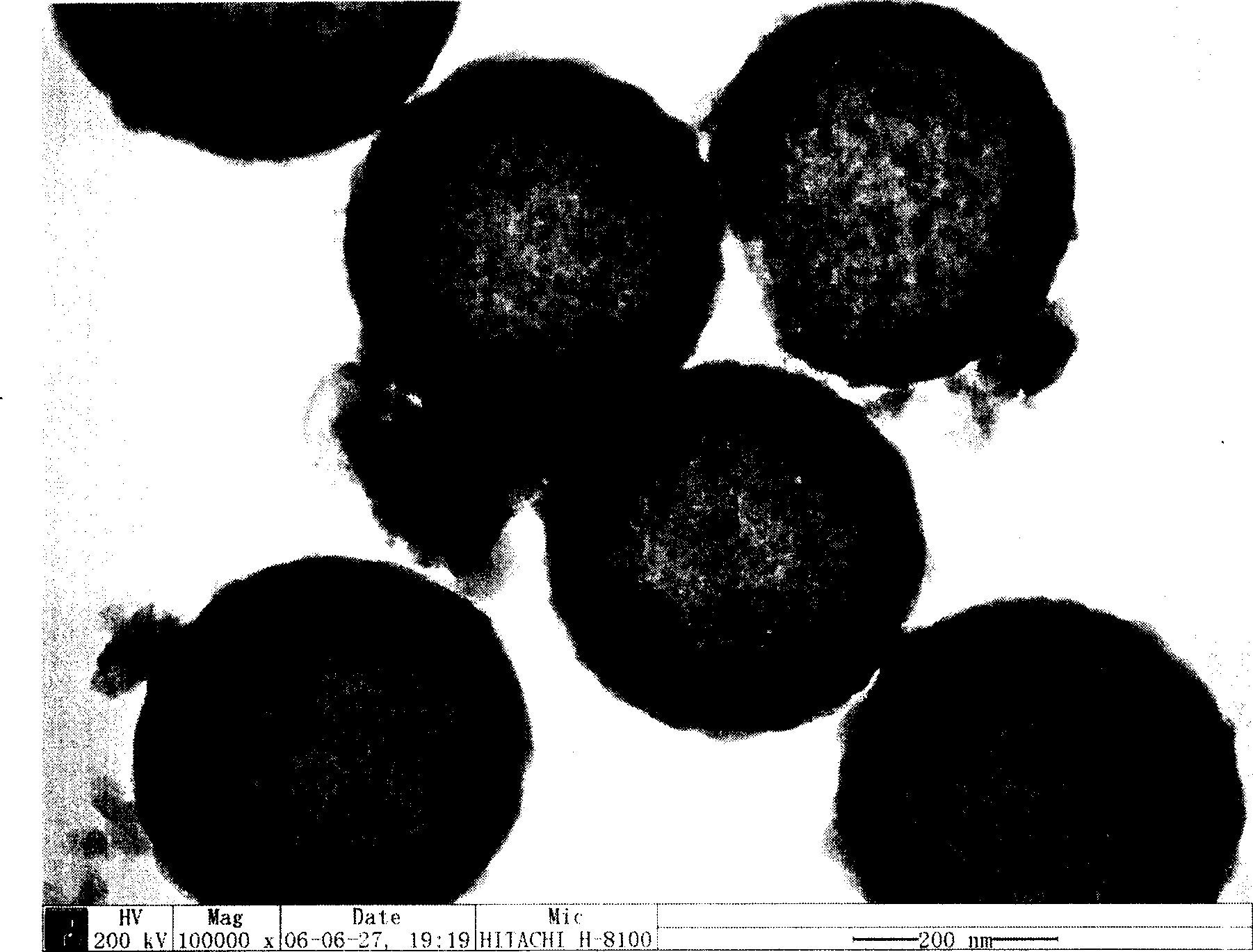

Hollow structured magnetic microsphere coated with mono-dispersed silicon dioxide and its preparation method

A technology of silica and magnetic microspheres, which is applied in the field of magnetic nanomaterials, can solve the problems of poor controllability and uniformity of the particle size of magnetic nanoparticles, no surface modification of the particles, no template removal, etc., and the preparation method is simple and easy Row, uniform number of nuclei, strong acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 Synthesis of Ferrite Nanoparticles: Fe 3 o 4 Preparation of nanoparticles

[0024] Weigh 1g of FeCl 3 ·6H 2 O and 0.37 g FeCl 2 4H 2 O was dissolved in 20ml of water through nitrogen and deoxygenation to obtain a mixed solution. Take 130ml of water in a 250mL round-bottomed flask, pass nitrogen to remove oxygen, add 12.5ml of concentrated ammonia water with a mass percentage concentration of 25-28%, pour the above-mentioned iron salt mixed solution into it quickly under vigorous stirring, and heat at 80°C Under reaction 1h. After the reaction is completed, use a 0.1T permanent magnet to separate the black solid from the reaction solution, and wash the obtained solid with high-purity water for 3 to 5 times to obtain Fe with a particle size of 6 to 10 nm. 3 o 4 Nanoparticles.

[0025] Will Fe 3 o 4After the nanoparticles were fixed to a volume of 6 mg / ml, 20 ml was taken out and sonicated for 10 minutes to obtain a ferrite nanoparticle sol for compoun...

Embodiment 2

[0026] Example 2 Synthesis of Ferrite Nanoparticles: CoFe 2 o 4 Preparation of nanoparticles

[0027] Weigh 1g of FeCl 3 ·6H 2 O and 0.38 g CoCl 2 4H 2 O was dissolved in 20ml of water through nitrogen and deoxygenation to obtain a mixed solution. Take 130ml of water in a 250mL round-bottomed flask to pass through nitrogen to remove oxygen, add 12.5ml of concentrated ammonia water with a concentration of 25-28% by mass, and quickly pour the above mixed salt solution into it under vigorous stirring. Reaction 1h. After the reaction is completed, use a 0.1T permanent magnet to separate the black solid from the reaction solution, and wash the obtained solid with high-purity water for 3 to 5 times to obtain CoFe with a particle size of 3 to 13 nm. 2 o 4 Nanoparticles.

[0028] CoFe 2 o 4 Nanoparticles are ultrasonically dispersed in water to obtain ferrite nanoparticle sol.

[0029] CoCl can be 2 Change to MnCl 2 or ZnCl 2 get the corresponding MnFe 2 o 4 or ZnFe ...

Embodiment 3

[0030] Example 3 Synthesis of polymer microspheres: Synthesis of polystyrene-acrylic acid (PS-AA) polymer microspheres

[0031] Add 100ml of water and 0.12g of NaHCO into a 250ml three-necked bottle 3 , 5ml styrene (St) and 0.5ml acrylic acid (-AA), pass N 2 After half an hour, it was placed in a water bath at 70° C., 0.05 g of potassium persulfate (KPS) was added and reacted for 10 h under mechanical stirring to obtain polystyrene-acrylic acid microspheres with a particle size of 300 nm.

[0032] If 8g of sodium dodecylbenzenesulfonate is added to the reaction system, polymer microspheres with a particle diameter of 80nm are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com