Magnetic field gel injection molding method for large scale rare-earth sintering magnet

A technology of gel injection molding and sintering magnets, which is applied in the fields of inorganic material magnetism, inductor/transformer/magnet manufacturing, electrical components, etc. The effect of reducing, residual oxygen and carbon residue, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] NdFeB powder is commercially available jet mill powder with a purity of 99.9% and an average particle size of 3.7μm; the chemical composition of the powder is Nd 2 Fe 14 B matrix phase components; hydroxyethyl acrylate, solvent toluene, initiator benzoyl peroxide, catalyst dimethylaniline, oleic acid are all analytically pure.

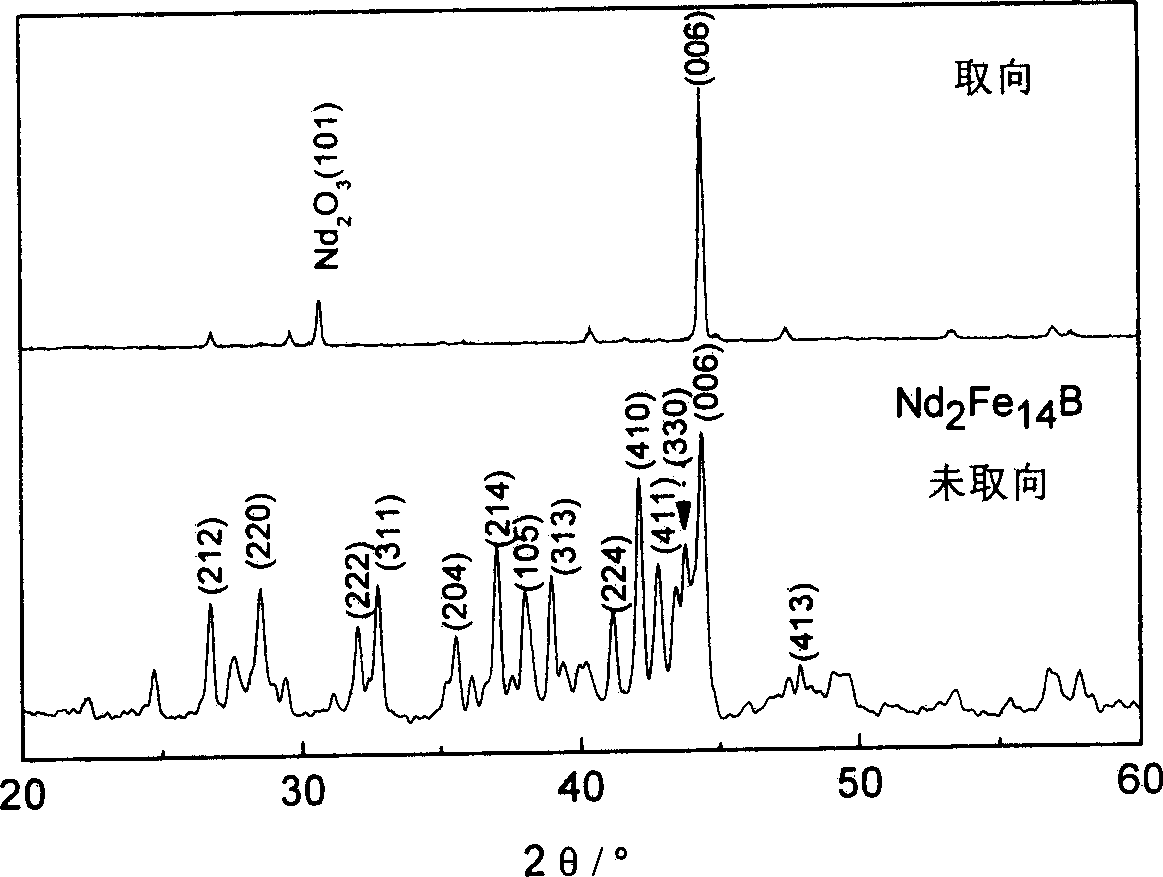

[0032] Dissolve 30ml of hydroxyethyl acrylate in 70ml of toluene, add 760g of NdFeB powder and 3g of polyacrylic acid dispersant, add initiator and catalyst after ball milling for 24 hours, and vacuum defoam for 30 minutes to obtain a solid phase volume fraction of 50% Slurry. Inject the slurry into a plastic mold, keep the mold in a magnetic field at 80°C for 60 minutes, and vacuum dry for 12 hours after demolding to obtain a magnetic field gel injection molded magnet body; the body is sintered and heat treated to obtain NdFeB Sintered magnet. The X-ray diffraction spectrum of the vertical orientation cross section of the sintered NdFeB magnet prep...

Embodiment 2

[0034] The composition of Sm-Co alloy powder is Sm(Co 0.72 Fe 0.17 Cu 0.08 Zr 0.03 ) 7.5, The average particle size is 4.1μm; hydroxyethyl acrylate, solvent toluene, initiator benzoyl peroxide, catalyst dimethylaniline, oleic acid are all analytically pure.

[0035] Dissolve 10 grams of hydroxyethyl acrylate in 90 milliliters of toluene to make a solution, add 840 grams of titanium powder and 6 grams of polyacrylamide dispersant, add initiator and catalyst after ball milling for 24 hours, and vacuum defoam for 20 minutes to obtain a solid A slurry with a phase volume fraction of 50%. Inject the obtained slurry into a glass mold, heat the mold in a magnetic field at 60°C for 120 minutes, and solidify the slurry in the mold into a green body. After demolding, vacuum dry for 48 hours to obtain a magnetic field gel injection molded magnet body; SmCo sintered magnet is obtained after the green body is sintered and heat treated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com