Water soluble flexible print plate and its producing method

A production method and technology for flexographic printing plates, applied in the field of flexographic printing plates, can solve the problems of prolonged drying time, increased plate-making cost, high damage intensity, etc., and achieve the effects of no environmental pollution, low cost, and good quality effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

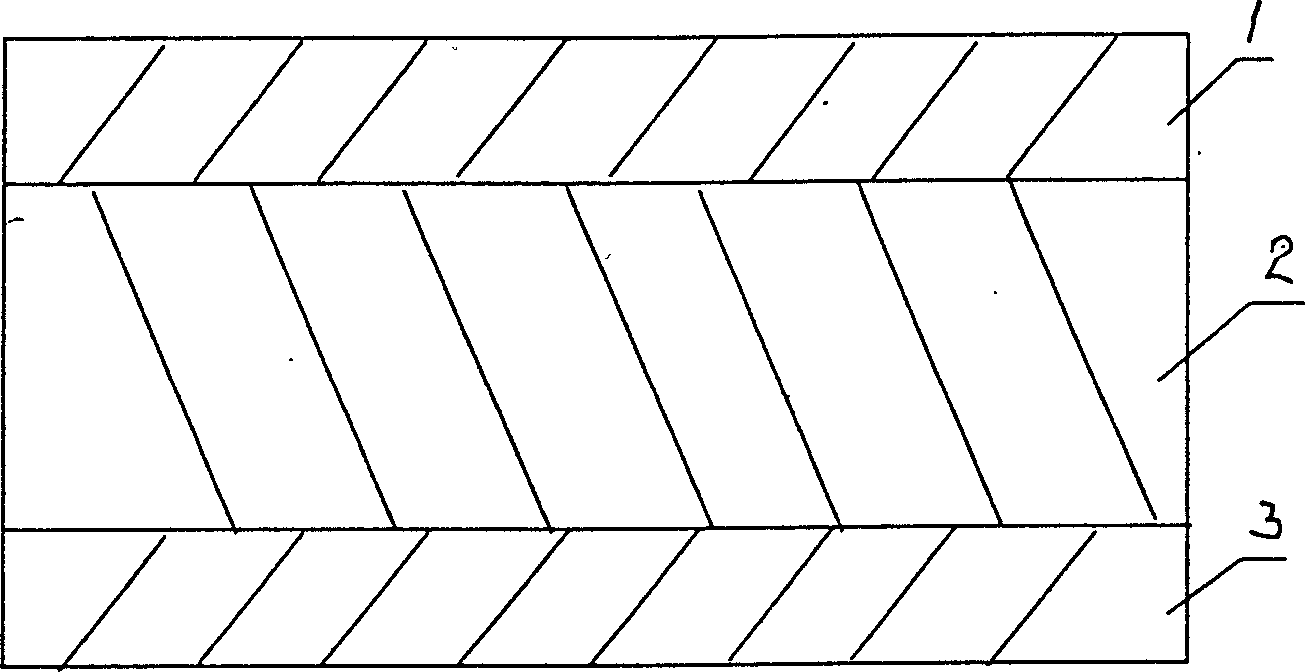

[0045] As shown in the accompanying drawings, a water-soluble flexo printing plate of the present invention consists of three parts: a polyester film protective layer 1 , a flexible photosensitive resin plate 2 and a polyester film base layer 3 . The composition of the flexible photosensitive resin plate includes: a main polymer composed of 05-88 polyvinyl alcohol, liquid rubber and reagent grade glycerol modifier, a methylol acrylamide crosslinking agent, acrylic acid Hydroxyethyl ester plasticizer, 1173 photosensitizer, p-hydroxyanisole antioxidant and caprolactam auxiliary agent, wherein the 05-88 polyvinyl alcohol in the host polymer is a commercially available low polymerization degree polymer chemical Medicine, it is a kind of water-soluble polymer, no matter in cold water or in hot water, it can dissolve very quickly, and shows its maximum solubility.

[0046] The production method of the flexo printing plate consists of (1), the production of prefabricated photosensiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com