Process for preparing water soluble cyclodextrin-C60 super molecule inclusion compound

A technology of cyclodextrin and clathrate, which is applied in the field of preparation of cyclodextrin-C60 supramolecular clathrate, can solve the problems of long time, low efficiency, unmatched size, etc., and achieve low energy consumption and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Prepare C60 negative ion solution

[0032] The molar ratio of sodium and naphthalene is mixed at a ratio of 1:1.1, and then added to the DMF solution, and the sodium is stirred and dissolved in the solution under the protection of an inert gas to obtain a naphthalene anion solution, and the reaction time is 1 hour. Add C60 with a molar ratio of 1:5 to the above solution, and stir for 1 hour under the protection of an inert gas to obtain a C60 negative ion solution.

[0033] The second step: carry out inclusion reaction

[0034] In the C60 anion solution prepared in the first step, add gamma-cyclodextrin with a molar ratio of 2:1 to C60. Stir for 1 hour under the protection of inert gas to obtain γ-cyclodextrin-C60 anion clathrate.

[0035] The third step: oxidation reaction

[0036] In the γ-cyclodextrin-C60 negative ion clathrate solution obtained in the second step, add iodine that is 3 times the molar number of C60, and stir for 1 minute under the protecti...

Embodiment 2

[0039] Step 1: Prepare C60 negative ion solution

[0040] The molar ratio of potassium and 1-methylnaphthalene is mixed in a ratio of 1:3, and added to the DMF solution, and potassium is stirred and dissolved in this solution under the protection of an inert gas to obtain a 1-methylnaphthalene anion solution, and the reaction time is 5 Hour. Add C60 with a molar ratio of 1:20 to potassium in the above solution, and stir for 10 hours under the protection of inert gas to obtain a C60 anion solution.

[0041] The second step: carry out inclusion reaction

[0042] In the C60 negative ion solution prepared in the first step, α-cyclodextrin with a molar ratio of 100:1 to C60 was added. Stir for 10 hours under the protection of inert gas to obtain α-cyclodextrin-C60 anion clathrate.

[0043] The third step: oxidation reaction

[0044] In the α-cyclodextrin-C60 negative ion clathrate solution obtained in the second step, add iodine which is 10 times the number of moles of C60, and...

Embodiment 3

[0047] Step 1: Prepare C60 Negative Ion Solution

[0048] The molar ratio of sodium and 1-methylnaphthalene is mixed in a ratio of 1: 1.5, and added to the DMF solution, and the sodium is stirred and dissolved in this solution under the protection of an inert gas to obtain an anion solution of 1-methylnaphthalene, and the reaction time is 3 Hour. Add C60 to the above solution with a molar ratio of 1:10 to sodium, and stir for 5 hours under the protection of an inert gas to obtain a C60 anion solution.

[0049] The second step: carry out inclusion reaction

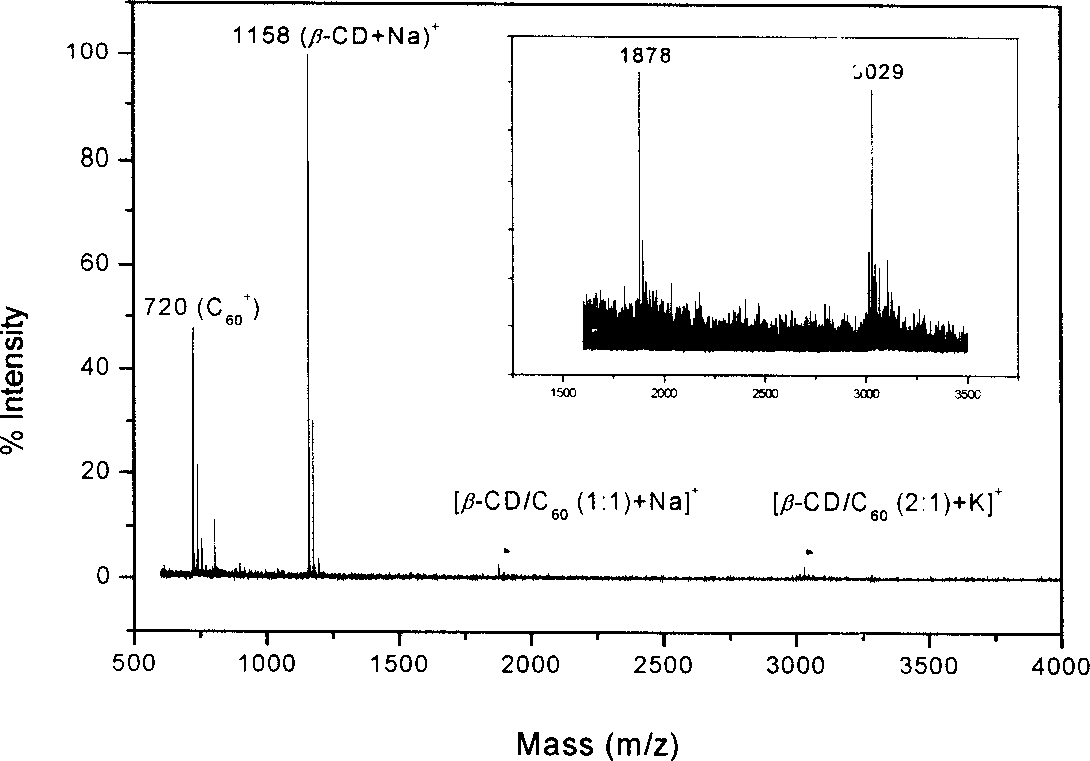

[0050] In the C60 negative ion solution prepared in the first step, add β-cyclodextrin with a molar ratio of 5:1 to C60. Stir for 5 hours under the protection of inert gas to obtain β-cyclodextrin-C60 anion clathrate.

[0051] The third step: oxidation reaction

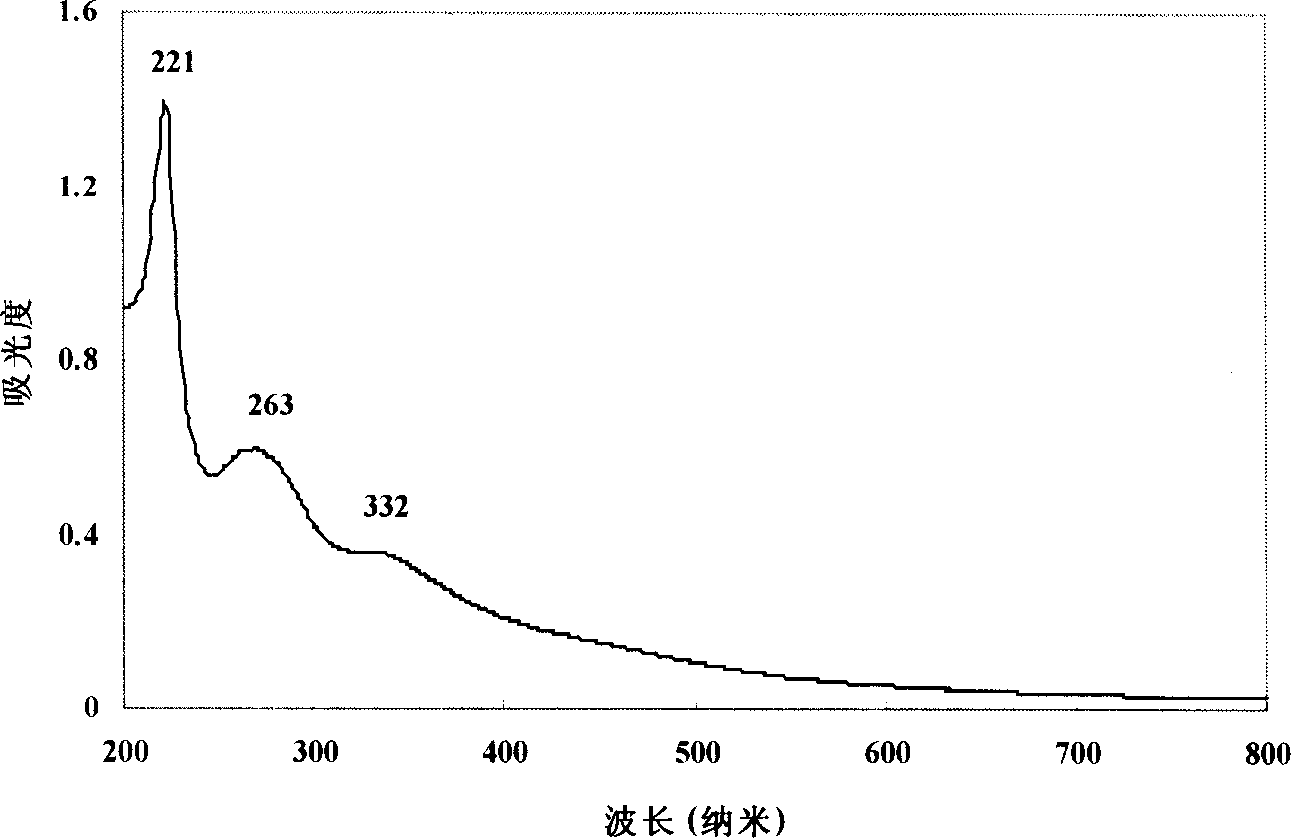

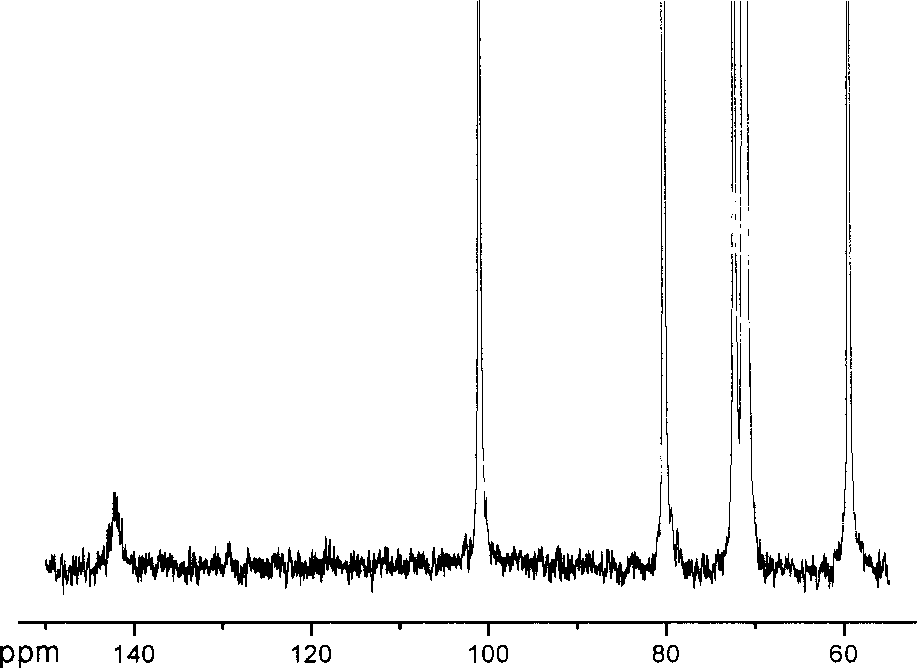

[0052] In the β-cyclodextrin-C60 negative ion clathrate solution obtained in the second step, add iodine that is 5 times the molar number of C60, and stir for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com