Novel phase change memory and its forming method

一种存储元件、相变化的技术,应用在电气元件、半导体器件、电固体器件等方向,能够解决复杂、高成本等问题,达到写入电流降低、降低制程复杂度及成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above and other objects, features, and advantages of the present invention more comprehensible, a preferred embodiment is specifically cited below, and is described in detail in conjunction with the accompanying drawings as follows:

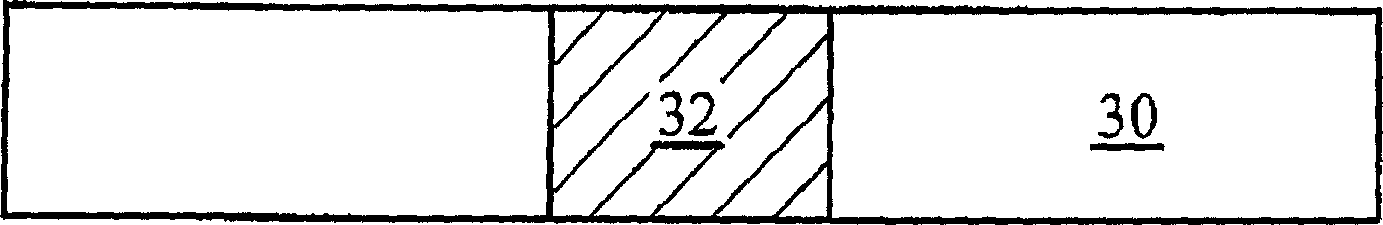

[0031] Such as Figure 3A As shown, wires 32 and insulating layer 30 are formed in the first metallization layer. In a preferred embodiment, the wires 32 are formed by a metal etching process, and then the insulating dielectric layer 30 is formed, that is, an interlayer dielectric (ILD). The wire 32 can be a commonly used metal material, such as metal or metal alloy, including Al, AlCu, Cu, Ti, TiN or W. Conductor 32 forms part of a current drive circuit (not shown) to provide current to induce a phase change.

[0032] In other embodiments, such as Figure 3B As shown, the wire 32 is formed by a single damascene process, in which the insulating layer 30 is formed after patterning a photoresist (not shown), etching a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com