Microactuator, head gimbal assembly containing the same, and method of manufacturing the same and hard disk driver

一种微致动器、磁头的技术,应用在对齐磁盘上的磁道、驱动/移动记录头、支持头等方向,能够解决硬盘驱动器可靠性降低、微致动器110强度下降等问题,达到确保摆动范围、良好效果、提高强度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

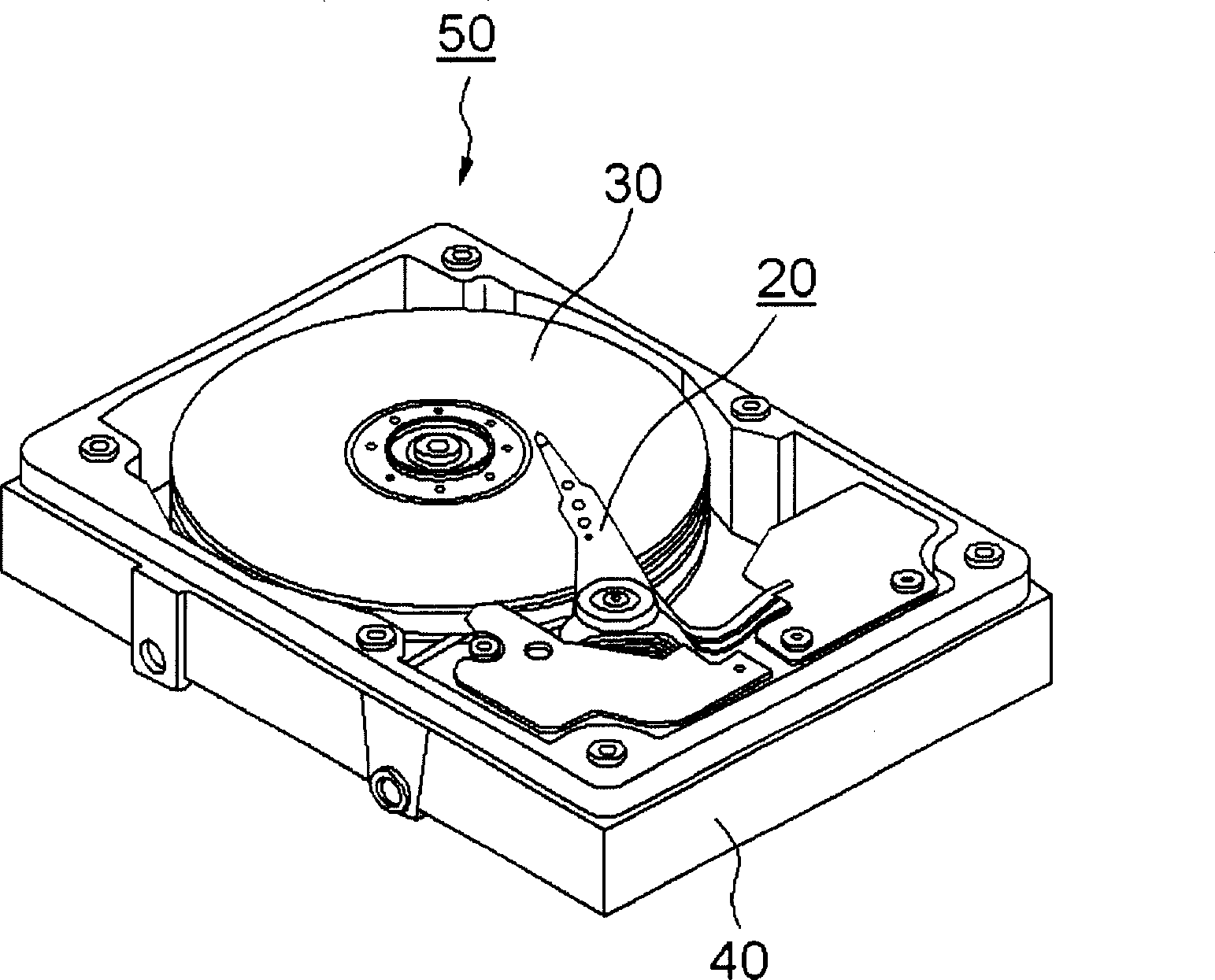

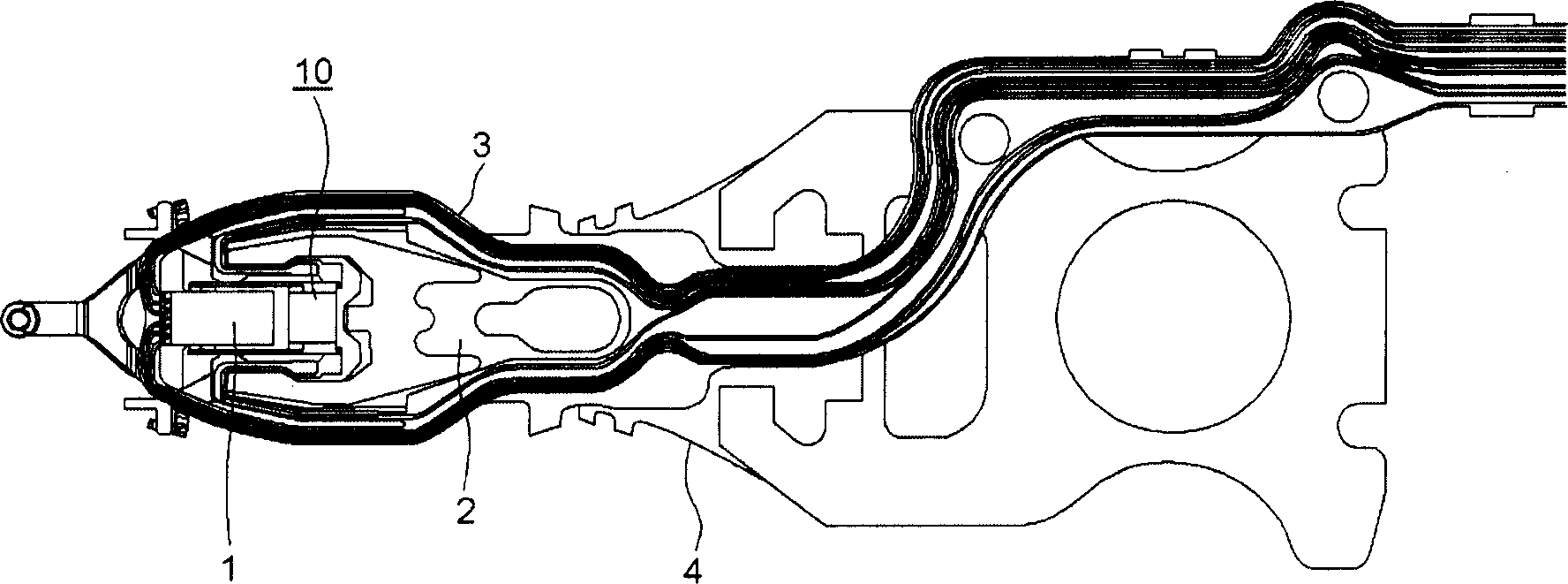

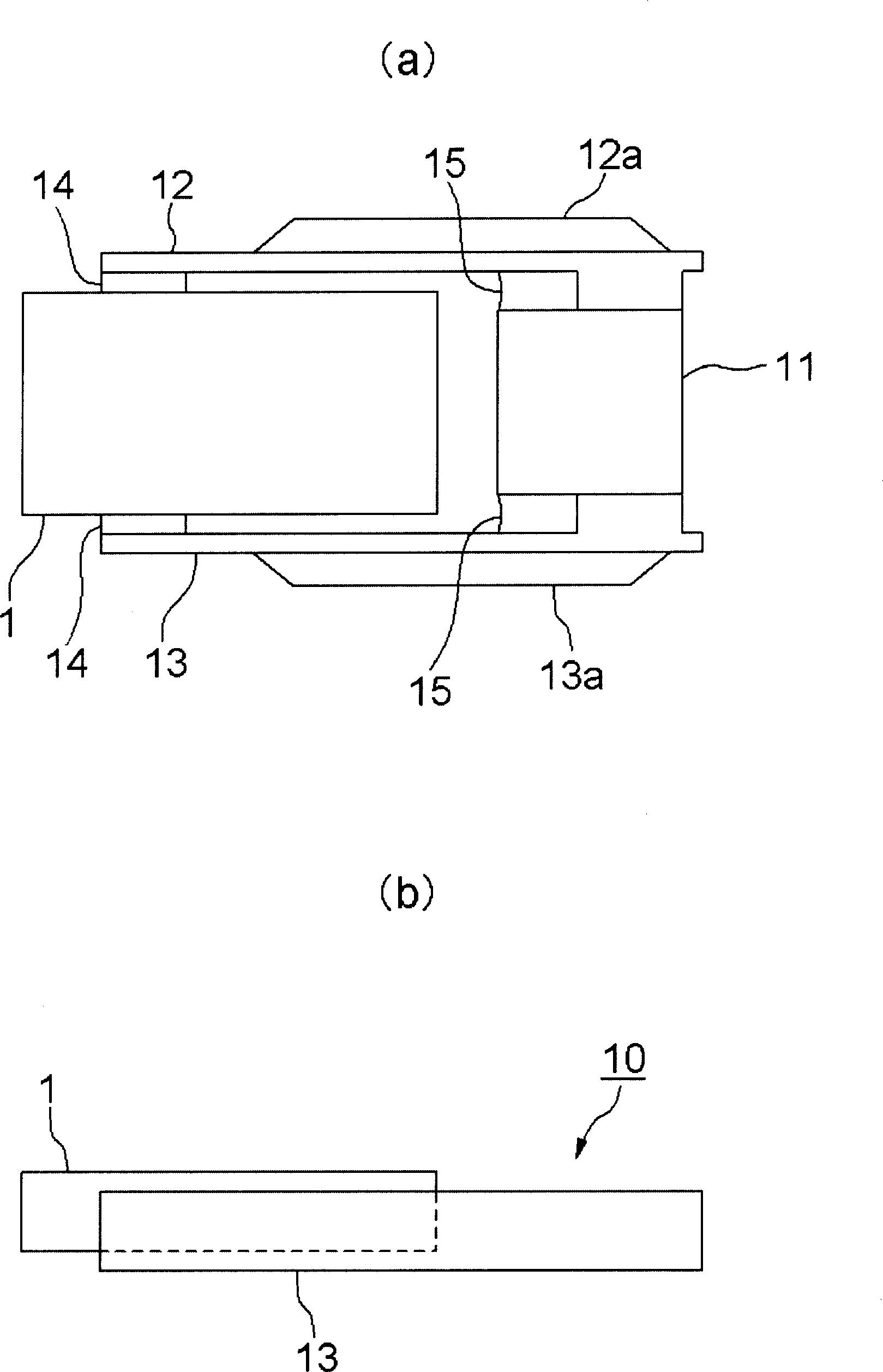

[0050] to combine Figure 1 to Figure 6 The first embodiment of the present invention is described as shown. in, figure 1 is a schematic diagram of the structure of a disk drive, figure 2 is a schematic diagram of the structure of the magnetic head gimbal assembly. image 3 It is a schematic diagram of the structure of the micro-actuator for the magnetic head. Figure 4 to Figure 5 It is an explanatory diagram showing the actuator mounting process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com