Method for verifying phase-shift angle of phase-shift photomask, photoengraving technology and phase-shift photomask

A technology of lithography process and phase shift angle, which is applied in the field of lithography, can solve the problems of time-consuming, quality reduction of lithography process, damage to the surface of photomask, etc., and achieve the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

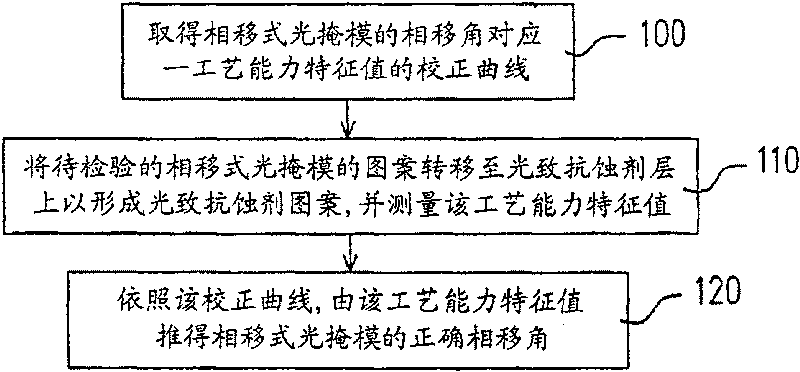

[0036] figure 1 A flowchart illustrating a method for inspecting a phase shift angle of a phase shift photomask of the present invention. Please refer to figure 1, first obtain a correction curve (step 100) corresponding to a process capability characteristic value of the phase shift angle of the specific type of phase-shift photomask to be used, wherein the type of phase-shift photomask is, for example, half-tone, alternating, none Chromium or any other type, the process capability characteristics are eg depth of focus, focus position or CD of photoresist pattern. For example, this calibration curve can be obtained by using a series of phase-shift photomask standard plates with known and different phase-shift angles to carry out the photolithography process, and then plotting the measured process capability characteristic value against the phase-shift angle, wherein each The phase shift angle of the phase shift photomask standard sheet can be accurately measured by the afor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com