Plate type heat exchanger and method of manufacturing the same

A manufacturing method and flat-plate technology, applied in indirect heat exchangers, cooling/ventilation/heating transformation, heat exchange equipment, etc., can solve the problem of reduced cooling capacity of heat pipes, unsmooth phase change and movement of working fluid, and sealing operations In order to achieve the effect of high cooling efficiency, suppress the deviation of heat carrier transfer ability, and prevent the working fluid from boiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

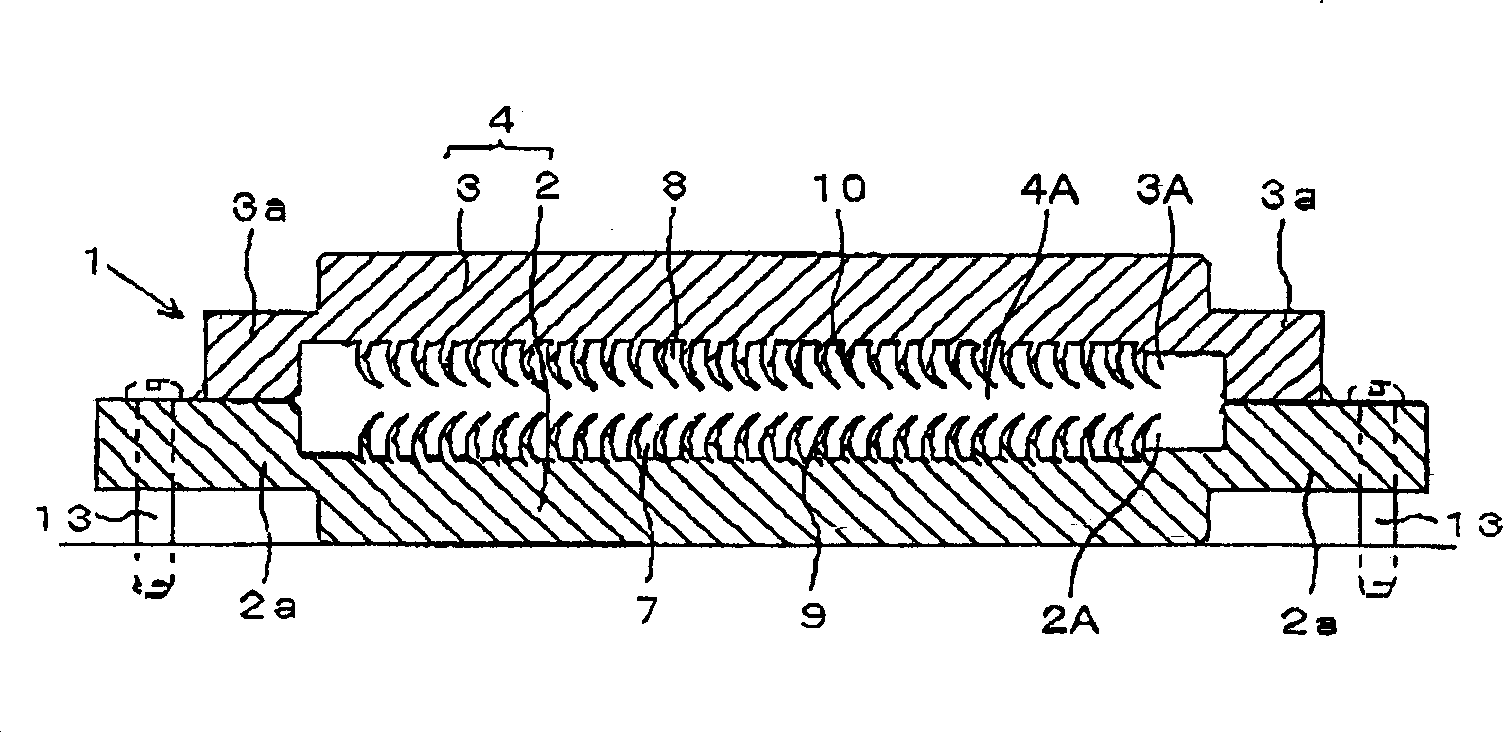

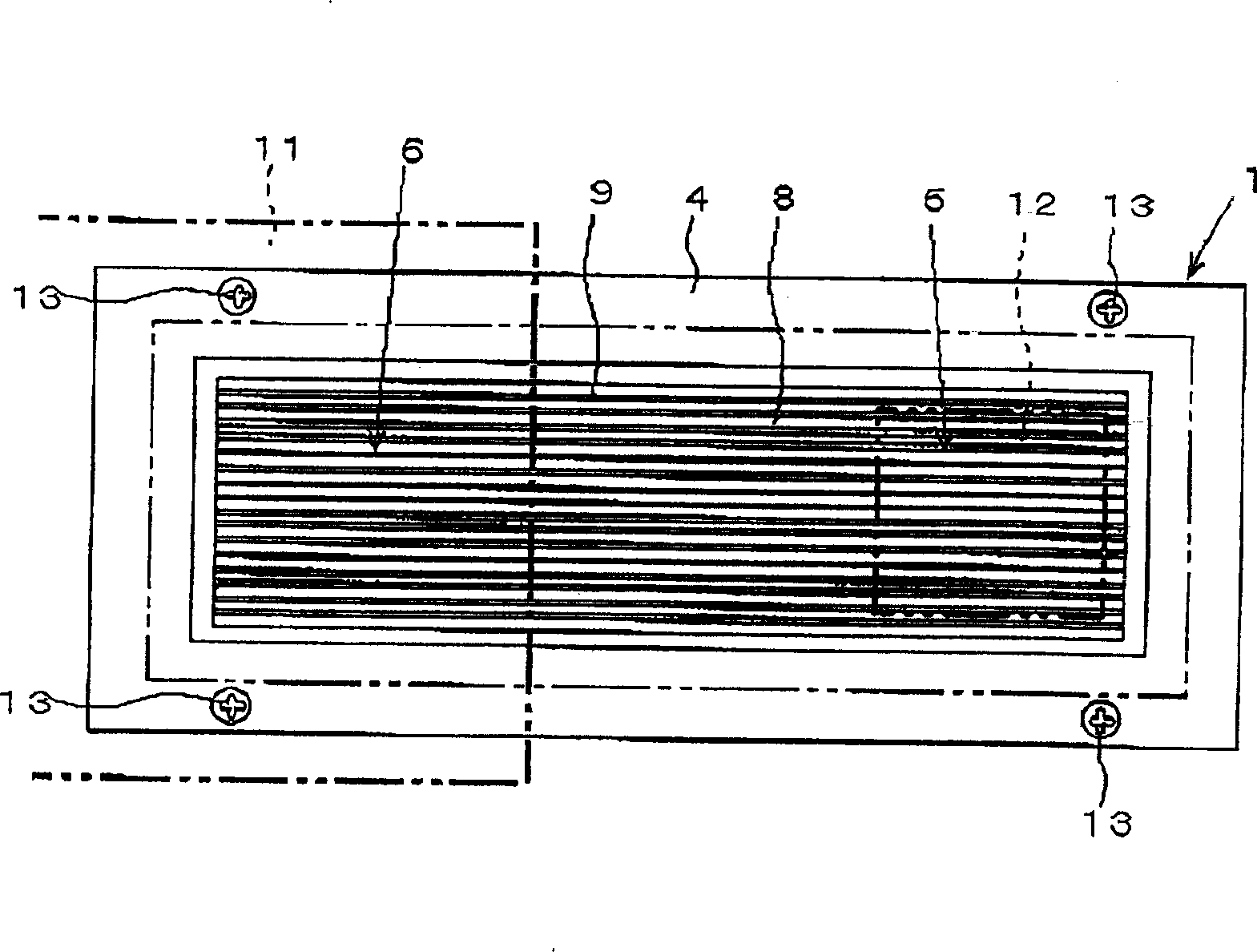

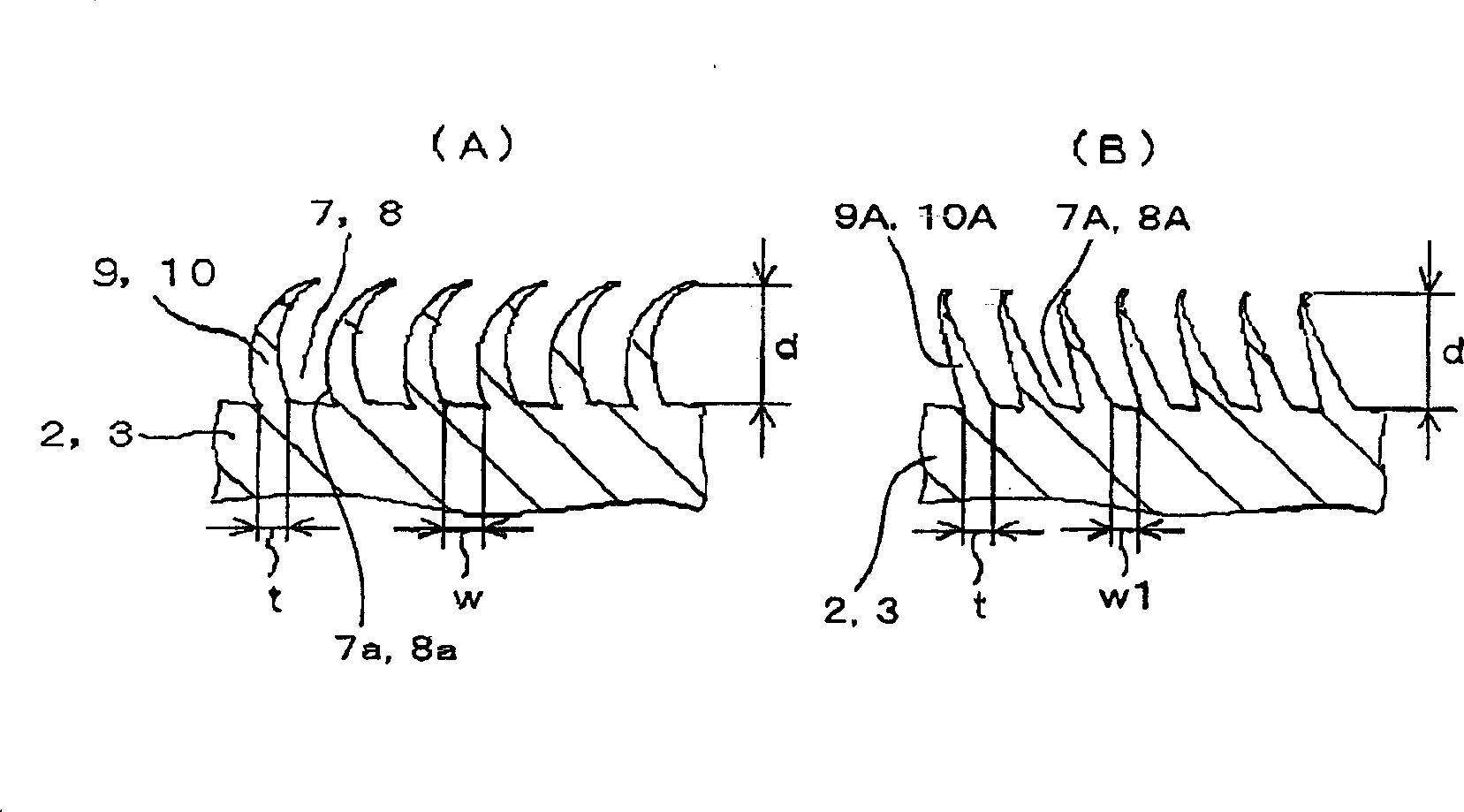

[0084] figure 1 It is a sectional view showing the flat heat pipe of Example 1, figure 2 is a plan view showing a flat heat pipe. The flat heat pipe 1 is sealed with a working fluid (heat carrier) in a hollow portion 4A of an airtight structure formed inside a flat rectangular container 4, and a guide groove as a heat carrier is formed on the inner surface portion of the container facing the hollow portion 4A. A plurality of grooves 7,8. The grooves 7 and 8 are formed between the condensation part 6 and the evaporation part 5 in the hollow part 4A, and the working fluid moves along the grooves 7 and 8 from the condensation part 6 to the evaporation part 5 by capillary force to dissipate heat.

[0085] The flat container 4 includes a rectangular lower container (container body) 2 and a rectangular upper container (container cover) 3 that covers the lower container 2, and the flat container 4 is formed by connecting the two rectangular frames Shaped mating surfaces, that is,...

Embodiment 2

[0134] Figure 17 is a cross-sectional view showing a flat heat pipe as a liquid-cooled flat heat exchanger according to Embodiment 2 of the present invention, Figure 18 is a plan view showing a flat heat pipe, Figure 19 It is a perspective view partially cut away of a flat heat pipe.

[0135] The container 104 of the flat heat pipe 101 includes a lower container 102 and a sealing member 103 covering the lower container 102 , and the container 104 is formed by joining and sealing the peripheries of both. A flat hollow portion 104A of an airtight structure is formed inside the container 104 . The sealing member 103 is formed in a substantially dish shape having a concave portion, and a groove portion 107 connecting the evaporating portion 105 and the condensing portion 106 is formed on the inner surface of the substantially flat plate-shaped lower container 102 . And, a working fluid is sealed in such a sealed hollow portion 104A. As the working fluid, pure water, substit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

| Bottom width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com