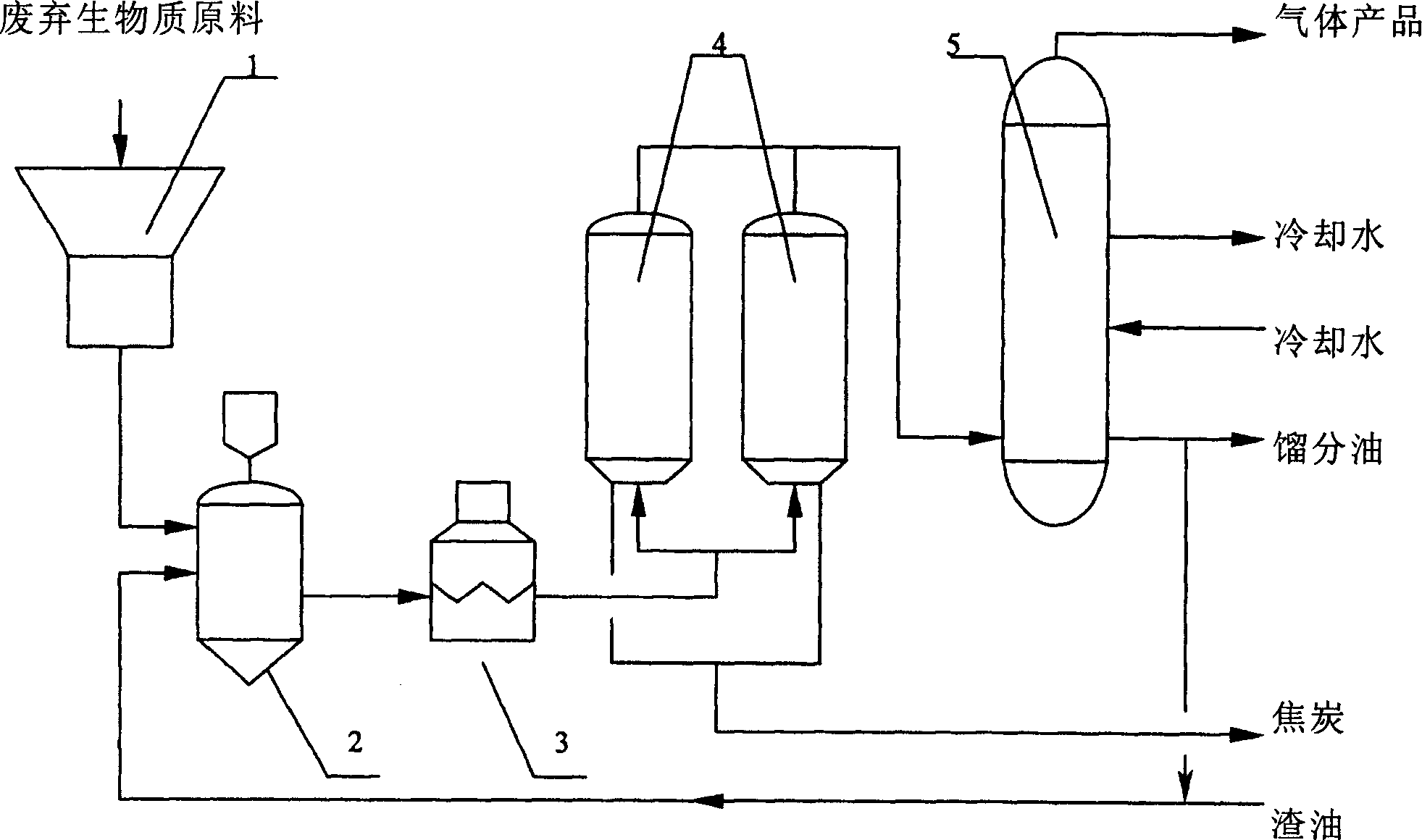

Delayed coking treatment method for waste biomass

A waste biomass and delayed coking technology, which is applied in cracking, non-catalytic thermal cracking, petroleum industry, etc., can solve the problems of not disclosing or prompting the treatment of waste biomass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Use fallen leaves as raw materials, crush them to an average particle size of 0.1mm, and then send them into a mixing tank to mix with residual oil and distillate oil, where the mixing mass ratio is 0.05%, and then send the mixed raw materials into the convection tube of the heating furnace Preheat to 190°C at a heating rate of 5°C / min, and then rapidly raise the temperature to 420°C at a heating rate of 20°C / min in the furnace tube of the radiation chamber of the heating furnace, where the operating pressure of the coke drum is 0.01MPa (gauge pressure). After the reaction and fractional distillation, the yield of distillate oil obtained is about 52.1% (dry basis), and the yield of coke is about 33.6% (dry basis).

Embodiment 2

[0045] Use waste wood as raw material, crush it to an average particle size of 2mm, and then send it into a mixing tank to mix with residual oil and distillate oil, wherein the mixing mass ratio is 15%, and then send the mixed raw material into the convection tube of the heating furnace Preheat to 300°C at a heating rate of 10°C / min, and then rapidly raise the temperature to 510°C at a heating rate of 80°C / min in the furnace tube of the radiation chamber of the heating furnace, wherein the operating pressure of the coke drum is 0.2MPa (gauge pressure). After the reaction and fractional distillation, the yield of distillate oil obtained is about 41.2% (dry basis), and the yield of coke is about 39.4% (dry basis).

Embodiment 3

[0047] Use straw as raw material, crush it to an average particle size of 0.2mm, and then send it into a mixing tank to mix with residual oil and distillate oil, wherein the mixing mass ratio is 5%, and then send the mixed raw material into the convection tube of the heating furnace Preheat to 240°C at a heating rate of 6°C / min, and then rapidly raise the temperature to 480°C at a heating rate of 50°C / min in the furnace tube of the radiation chamber of the heating furnace, where the operating pressure of the coke tower is 0.03MPa (gauge pressure). The yield of distillate obtained after reaction and fractionation is about 50.4% (dry basis), and the yield of coke is about 33.6% (dry basis).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com