Efficient mortar plasticizer base material and its efficient mortar plasticizer composition

A plasticizer and composition technology, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of increasing cement consumption, construction difficulties, insufficient dosage, etc. Plump, not easy to coagulate and break, and improve the effect of solution concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

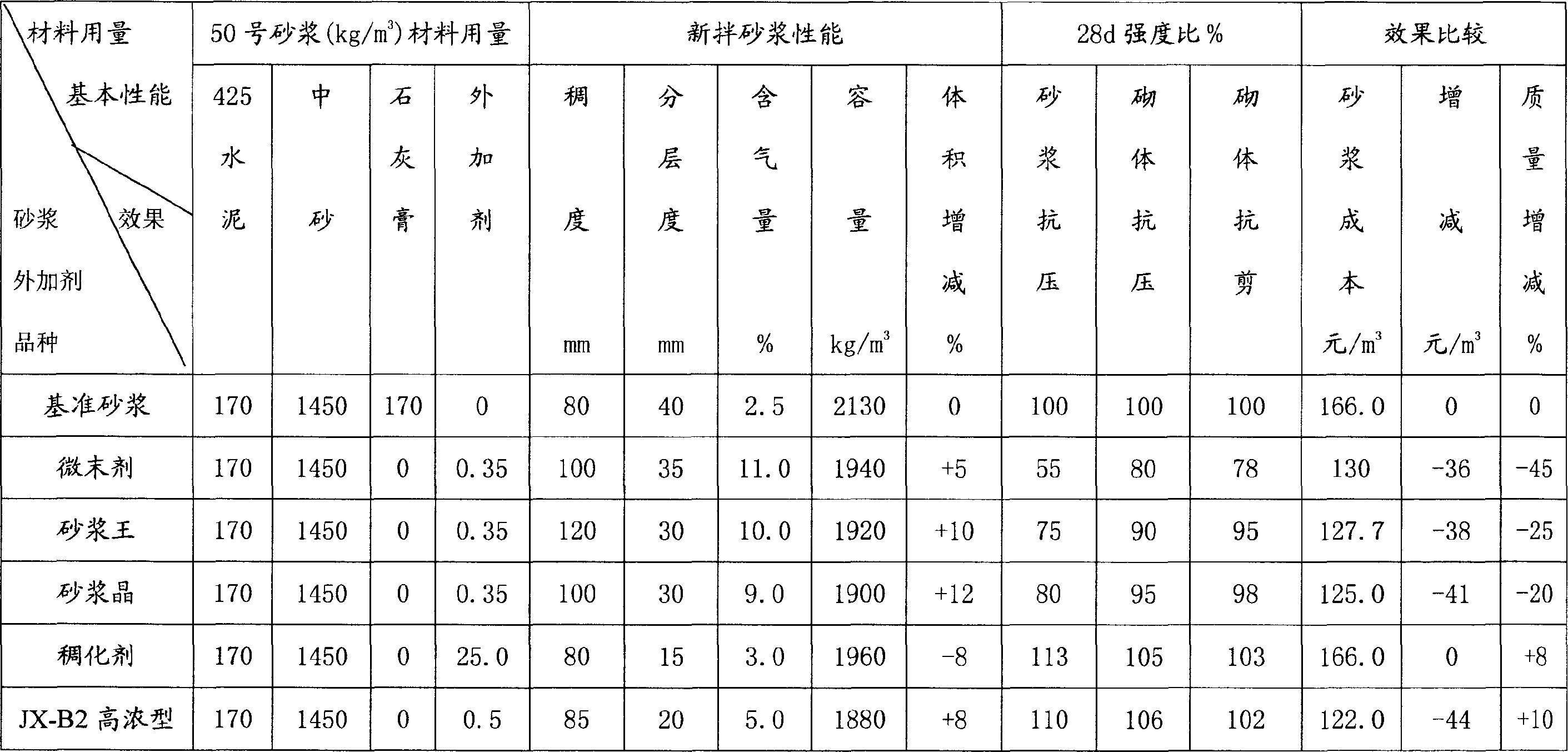

Image

Examples

Embodiment 1

[0042] First heat 45kg of water in the reactor to 100°C, slowly add 11kg of sodium abietate during stirring, after the rosin polymer is completely dissolved, slowly add 5kg of sodium hydroxide, and keep stirring, After the dissolution is complete, stop heating, and use boiling water to make up for the lost moisture; cool down to 60°C and react at a constant temperature for 4 hours until the reaction is complete, add 8kg of sodium dodecylbenzenesulfonate and 1kg of triethanolamine during the stirring process, Mix well, then react at a constant temperature at 60°C for 3 hours until the reaction is complete, then add 10kg of polycarboxylate superplasticizer, react at 40°C for 2 hours, and cool to room temperature. Finally, spray-dry to obtain 32kg of powdery granule products, add 4kg of hydroxyethyl methylcellulose and 9kg of microsilica powder (first-class fly ash) to compound into 45kg of high-efficiency mortar plasticizer base material.

Embodiment 2

[0044] Add 50kg of water to the reaction kettle, heat it to boiling water at 100°C, then slowly add 5kg of potassium hydroxide, and stir until it is completely dissolved, then slowly add 12.5kg of rosin powder to fully dissolve it, and cool down to 75°C After adding 2kg of triethanolamine and mixing well, add 10kg of sodium lauryl sulfate to fully dissolve and cool down to 50°C, add 12kg of sulfamate water reducer with a solid content of 40%, and react at a constant temperature of 35°C for 5 hours , until the reaction is complete, cooled to normal temperature, spray-dried into powder, and the dry powder with a weight of 35kg is compounded with 5kg of thickener hydroxyethyl cellulose and 10kg of silicon micropowder (first-grade fly ash) to form a total High-efficiency mortar plasticizer base material with a weight of 40kg.

[0045] High-efficiency mortar plasticizer composition embodiment

[0046] According to different purposes, use high-efficiency mortar plasticizer base mat...

Embodiment 3

[0051] Embodiment 3 (taking 1000kg as example)

[0052] High-efficiency mortar plasticizer composition (JX-B1 normal temperature type): use 300kg of high-efficiency mortar plasticizer base material, add 300kg of sodium lignosulfonate, 250kg of β-naphthalene sulfonate water-reducing plasticizer, and the balance is Fly ash, compounded evenly, measured and packaged as finished products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com