Ruthenium compounds, process for their preparation, and ruthenium-containing thin films made by using the compounds

The technology of a ruthenium compound and its manufacturing method, which is applied in the field of ruthenium-containing thin films, can solve problems such as the deterioration of vaporization characteristics, and achieve the effects of excellent step coating properties, surface morphology, and excellent electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

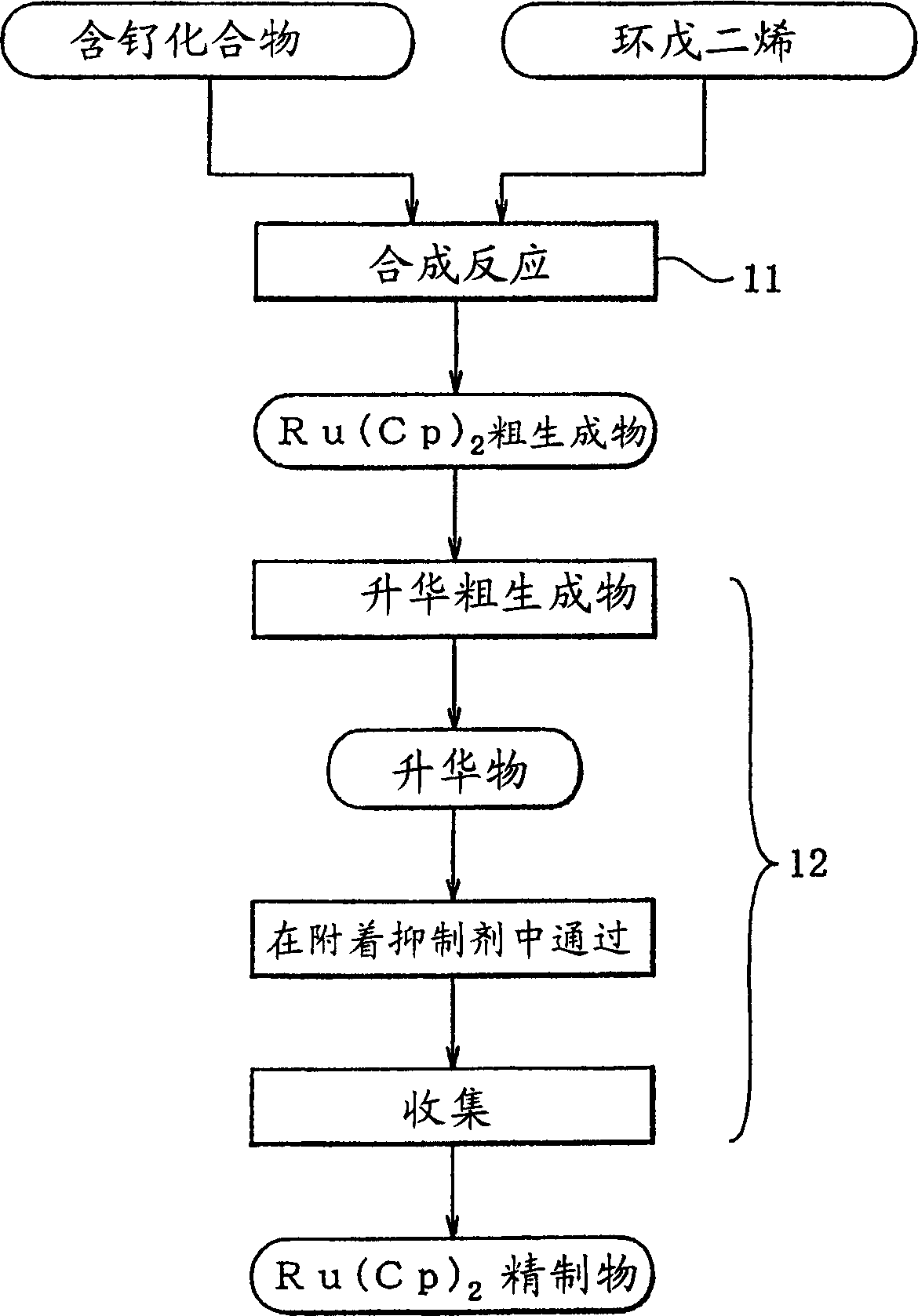

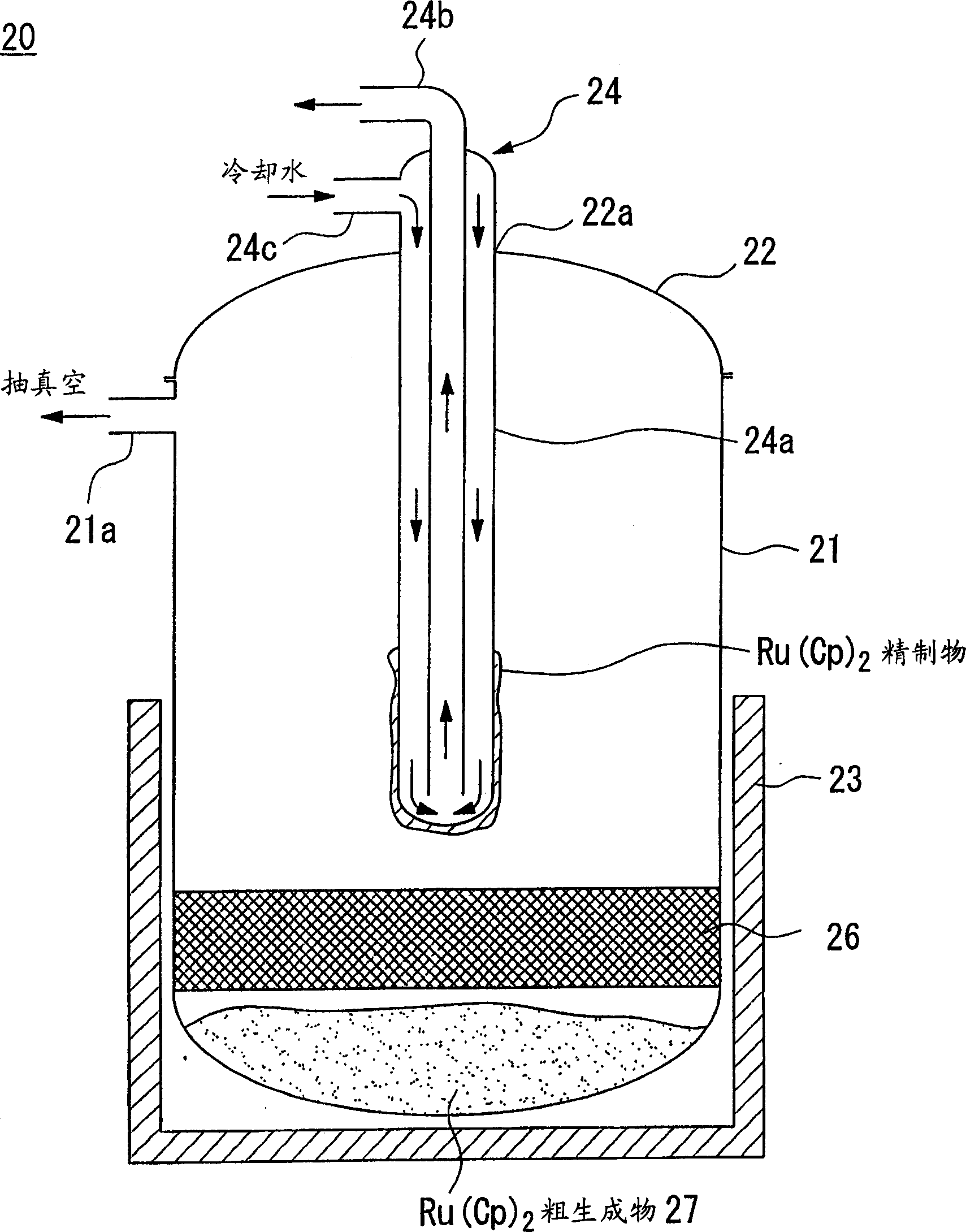

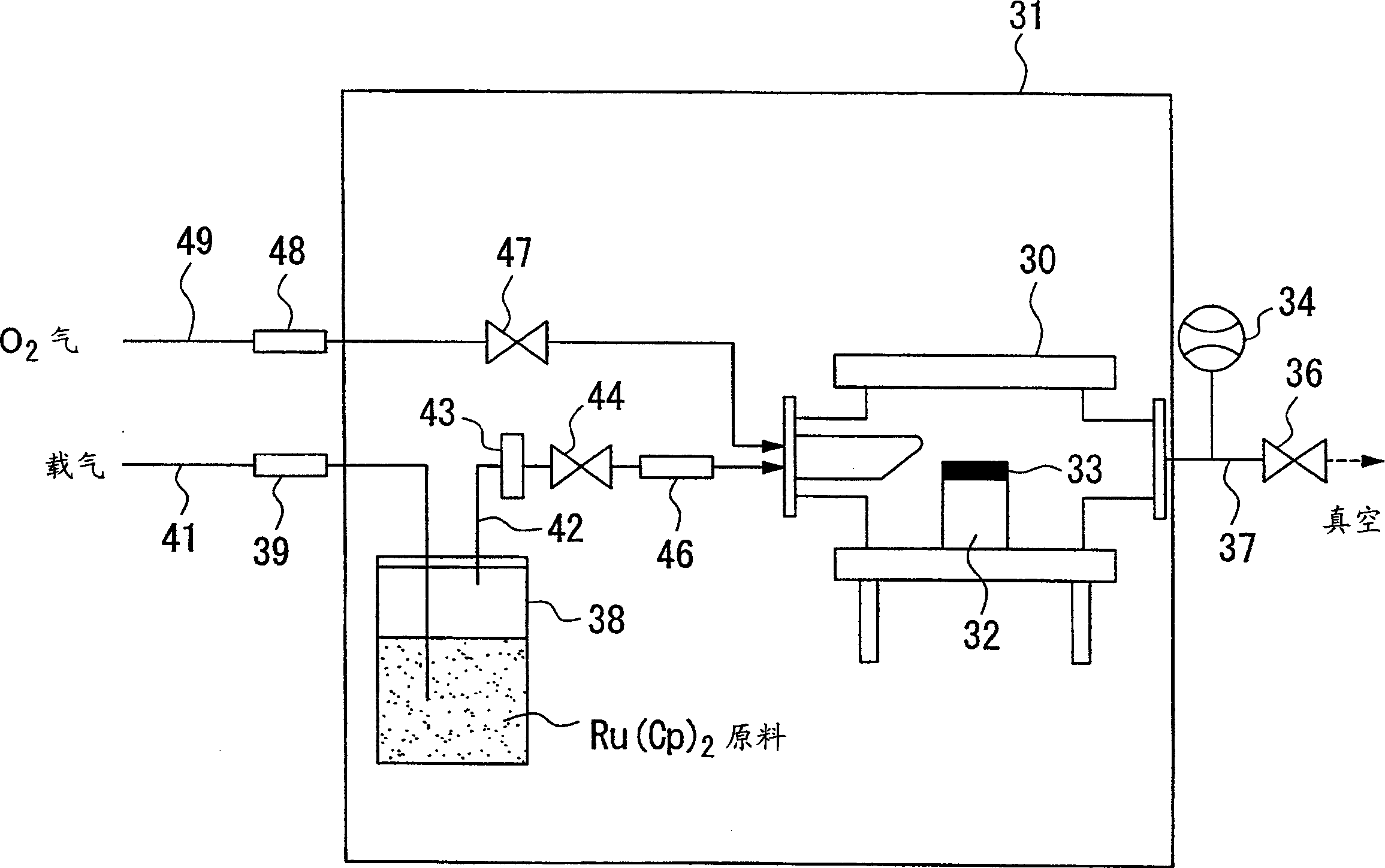

[0054] Refer to the attached Figure 1 Preferred embodiments of the present invention will be described. However, the present invention is not limited to the following embodiments, and for example, components of these embodiments may be appropriately combined.

[0055] [the first mode]

[0056] The inventors of the present inventors diligently studied the influence of impurities contained in the ruthenium compound on film formation using the MOCVD method. Optimizing the content of the film can achieve a moderate film-forming speed.

[0057] The ruthenium compound of the present invention is by Ru(Cp) 2 The ruthenium compound composed of a coordination compound is characterized in that the content of either or both of sodium and potassium in the compound is 5 ppm or less. When the impurity content exceeds 5 ppm, deterioration of vaporization characteristics occurs. The content of impurities is preferably 0-3 ppm. More preferably 0-2 ppm. More preferably, it is 0-1.5 ppm....

Embodiment 1

[0083] Ru(Cp) with a sodium content of 1.4ppm manufactured using an adhesion inhibitor made of glass fiber 2 The complexes are sealed in ampoules under argon atmosphere. The ampoule was heated to 200°C in a heating furnace and kept unchanged for 72 hours. The ampoules were removed from the oven and air cooled to return to room temperature. The vaporization characteristics of the ruthenium compound in the ampoule returned to room temperature were measured using a TG-DTA apparatus (manufactured by MAC-science). The measurement conditions of the TG-DTA device are shown in Table 1.

[0084]

Embodiment 2

[0086] Ru(Cp) with a potassium content of 1.7ppm manufactured using an adhesion inhibitor made of glass fiber 2 The vaporization characteristics of the complex were measured using a TG-DTA apparatus in the same manner as in Example 1 except that.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com