Oxidation method prepared whole-cotton stalk newspaper pulp and its preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

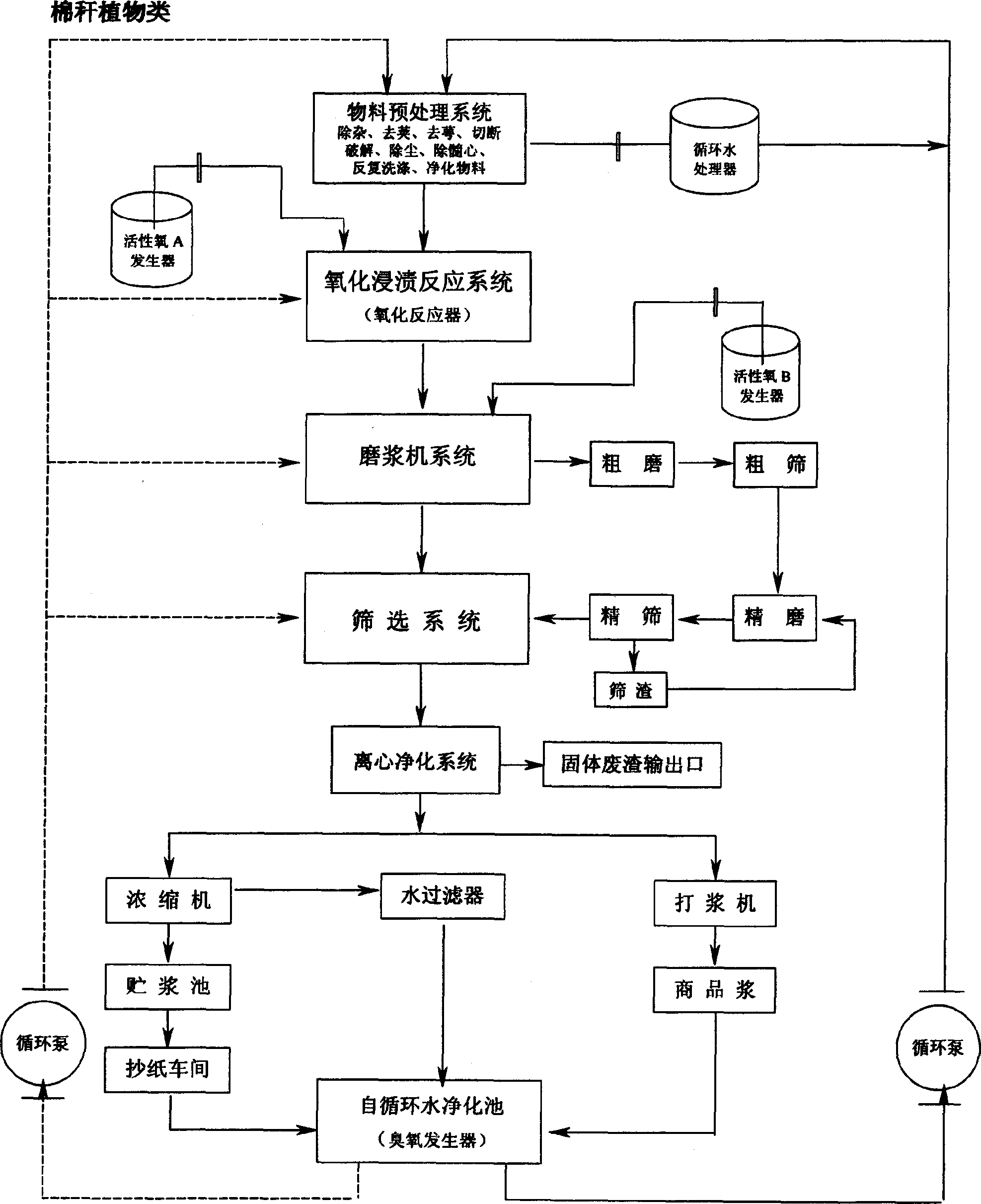

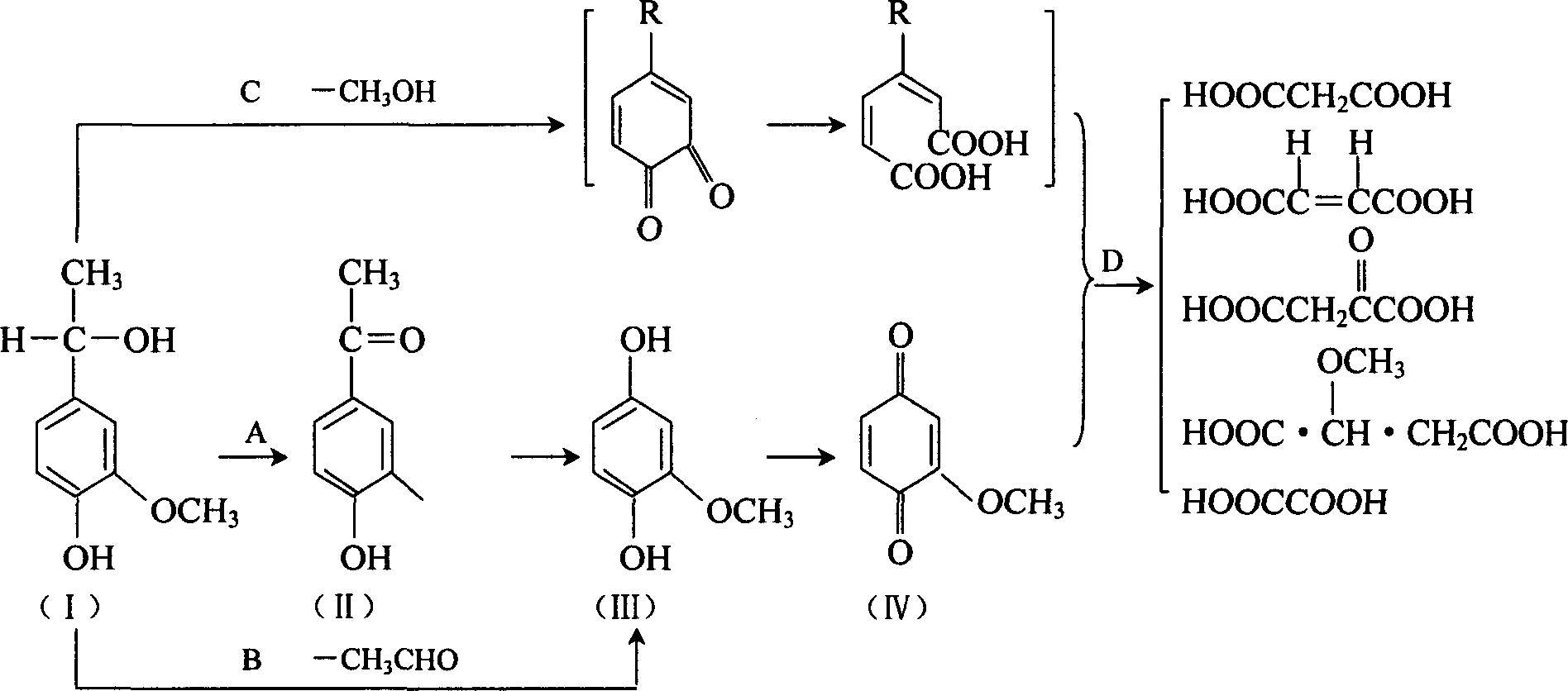

Method used

Image

Examples

Embodiment 1

[0048] 100kg of cotton stalks are removed with pods and calyx by cracking machine, cut into 10cm long and 1.5cm thick material, after cracking with hammer chip cracker, dust is removed by wind, pith core is removed, impurities are sieved, washed with circulating water, and input into belt In the immersion tank with an automatic stirrer, the temperature of the immersion tank is 50-80°C, the pH value of the water in the pool is 2.5, add 0.01kg of magnesium carbonate and 0.1kg of dimethyldioxirane (DMD), and the stirring speed is 60 / min , add H after 1h 2 o 2 Solution, control the concentration at about 0.2%, add a stirrer to accelerate 80 / min, pH=5.5, temperature 80°C, after 1.5 hours, observe that the material in the pool is soaked and the softness rate reaches 98%, and the material in the pool changes from dark yellow to light White, whiteness 48-52°, the material is washed repeatedly, squeezed dry and concentrated, the water content is 30%, and the washed material is added d...

Embodiment 2

[0050] With the original coarse slurry 100kg in the embodiment one, the screw feeder is evenly and continuously sent into the mill, the first time of fine grinding, in the fine grinding process, drop the prepared 0.4% H 2 o 2 , dripping amount and slurry ratio 1:0.12, mixed grinding with slurry, mill speed 1300 / min, mill gap adjusted to 0.20mm, temperature 60°C, slurry concentration up to 30%, pH value 2.5, slurry flow The speed is 1.5-2h, the whiteness of the pulp is observed to be 76-86°, the feeder feeds the finely refined pulp into the refiner, the speed is 1300 / min, the gap between the mills is adjusted to 0.20mm, the pulp concentration is 35%, and the feeding is about 10umol / L ozone and 0.02umol / L horseradish peroxidase, the acting pressure is 0.6MPa, mixed with the slurry for 0.5-1h, the pH value is 2.5, the slurry concentration is 35%, the temperature is 80°C, and the whiteness should be equal. 85°, enter the conventional fine screening, purification, cylinder thicken...

Embodiment 3

[0053] Repeat Example 1 to obtain the original coarse pulp.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com