Microflow chip and method for preparing polymer microsphere using same

A technology of microfluidic chips and microspheres, which is applied in the direction of immobilization on/in the organic carrier, block transportation, etc., which can solve the problems that it is difficult for organisms to be damaged, the diameter cannot be precisely controlled, and the distribution of microspheres is large in size, etc. problem, to achieve the effect of uniform size controllable, good shape and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

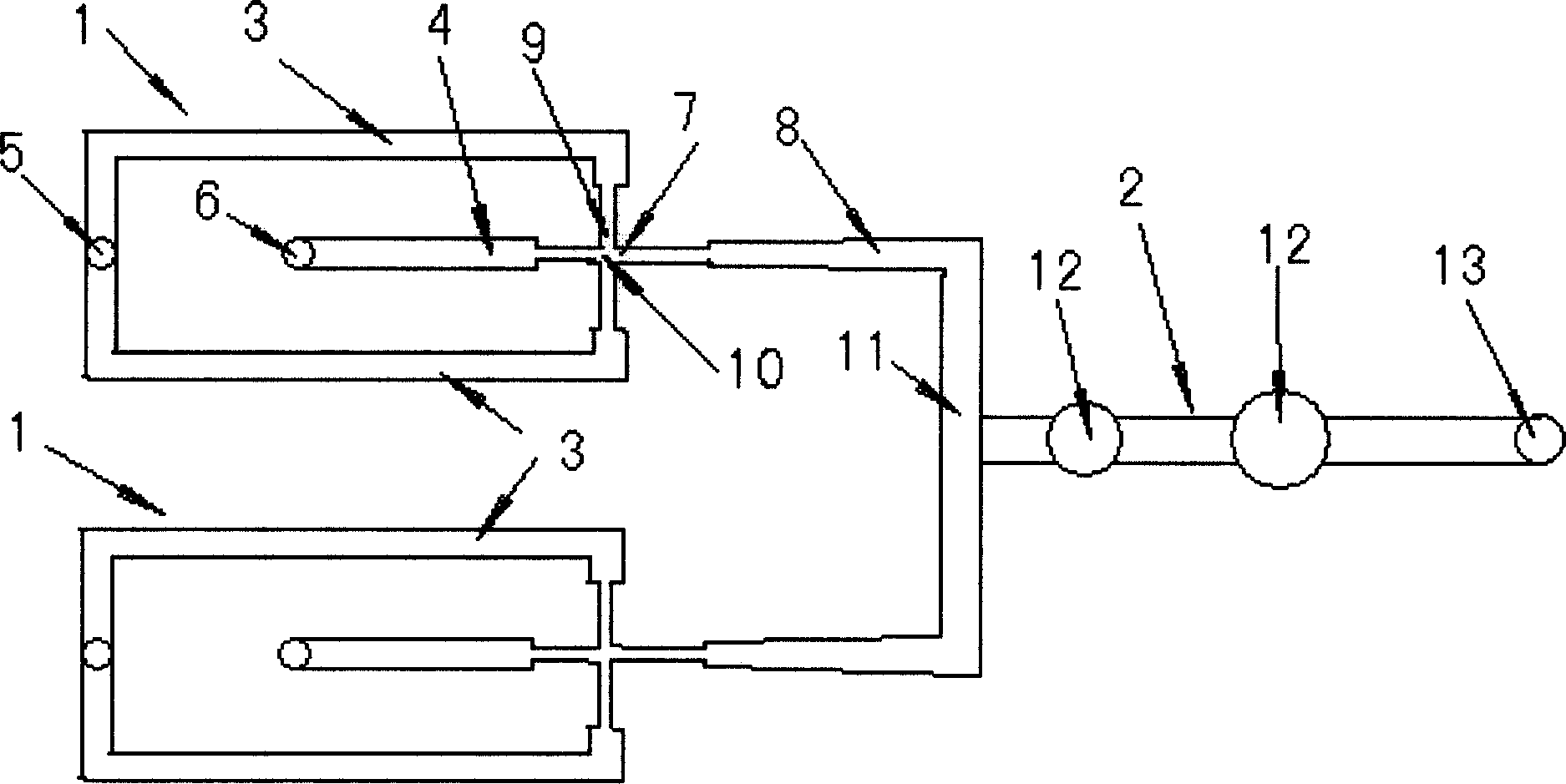

Method used

Image

Examples

Embodiment

[0019] 1-3% (mass ratio) sodium alginate and 0.5-5% (mass ratio) calcium chloride are added to the dispersed phase channel, oil is injected from the continuous phase channel, and the dispersed phase is at the input port of the prepolymer microsphere channel At , due to the extrusion of the continuous phase, a stable focused flow is formed, and due to the surface tension, drag force and shear force, the head of the focused flow breaks periodically to produce microspheres of uniform size. In order to achieve different prepolymer solution ratios, the oil speed and prepolymer solution speed can be changed. The flow rate of the prepolymer solution is respectively controlled at 1-2000 microliters / hour, and the flow rate of the oil is always controlled to be higher than the flow rate of the prepolymer solution.

[0020] Prepare sodium alginate and calcium chloride microspheres first: set the flow rate of the oil phase and sodium alginate solution, first use a flow focusing channel to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com