Welding alloy for sputtering target production and sputtering target

A technology for welding alloys and sputtering targets, which is applied in the field of sputtering targets and welding alloys for sputtering target manufacturing, can solve the problems of many processes, high costs, and reduced production efficiency, so as to improve production efficiency, prevent strength deterioration, Effect of reducing the amount of Cu corroded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

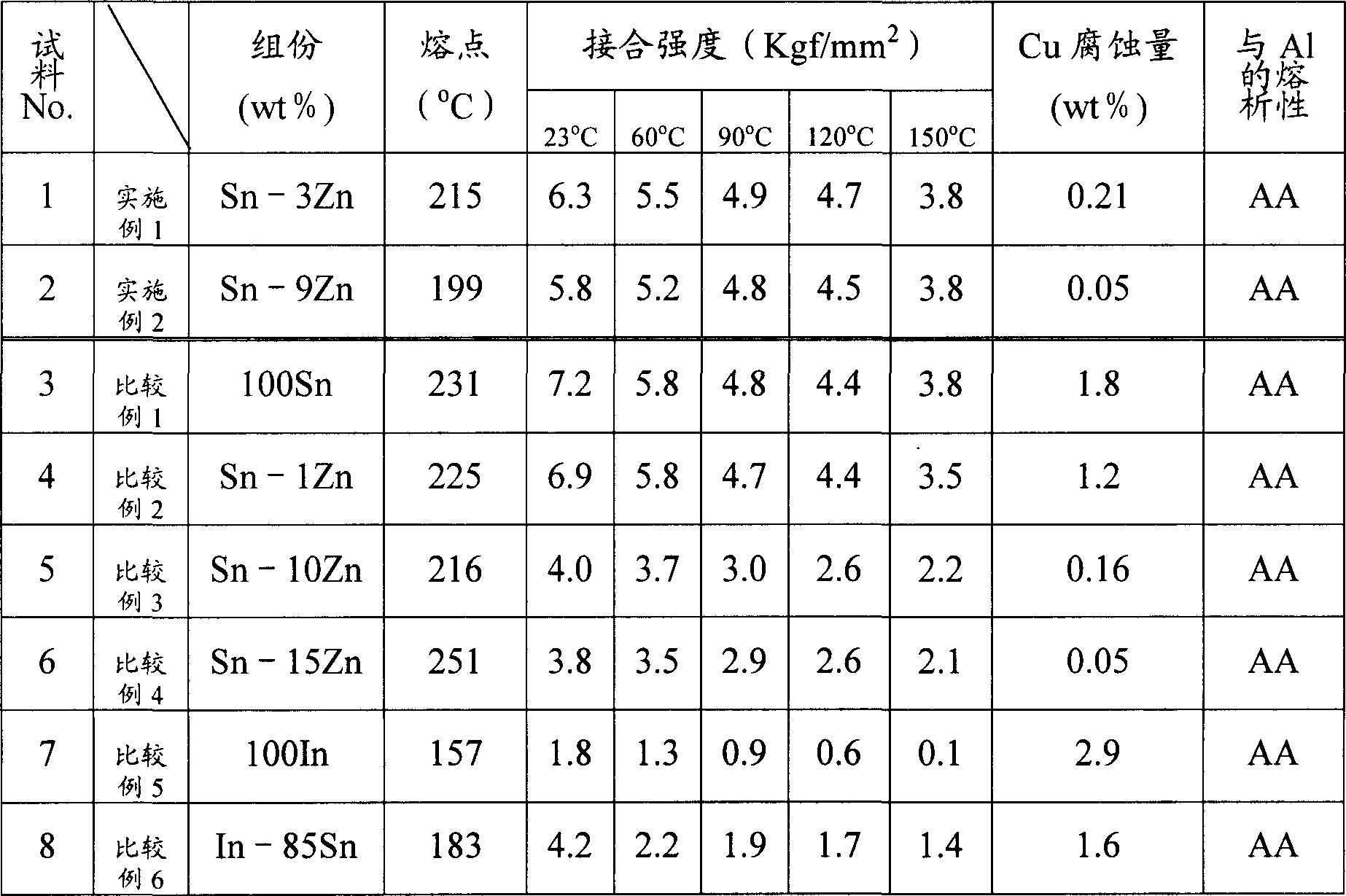

[0059] Embodiment 1~2, comparative example 1~6

[0060] Sn-Zn solder alloys with the ratio of Sn / Zn (weight %) = 97 / 3, 91 / 9 were prepared from raw materials Sn (purity 99.99%) and Zn (purity 99.99%) (referred to as sample No. 1, 2).

[0061] As a comparison, Sn-Zn solder alloys (referred to as sample No. ~6).

[0062] In addition, as a comparison, solder alloys with the ratio of In / Sn (weight %) = 100 / 0, 15 / 85 were prepared using raw materials In (purity 99.99%) and Sn (purity 99.99%) (referred to as sample No. 7, 8).

[0063] The (1) melting point, (2) temperature dependence of bonding strength, (3) corrosion amount of support plate (Cu), (4) and Al target of obtained samples No. 1 to 8 were analyzed by the following methods The dissolution property was evaluated. The results are shown in Table 1.

[0064] (1) Determination method of melting point

[0065] The above-mentioned samples No. 1 to 8 were respectively measured on a differential thermal analysis device TG-DTA...

Embodiment 3~17

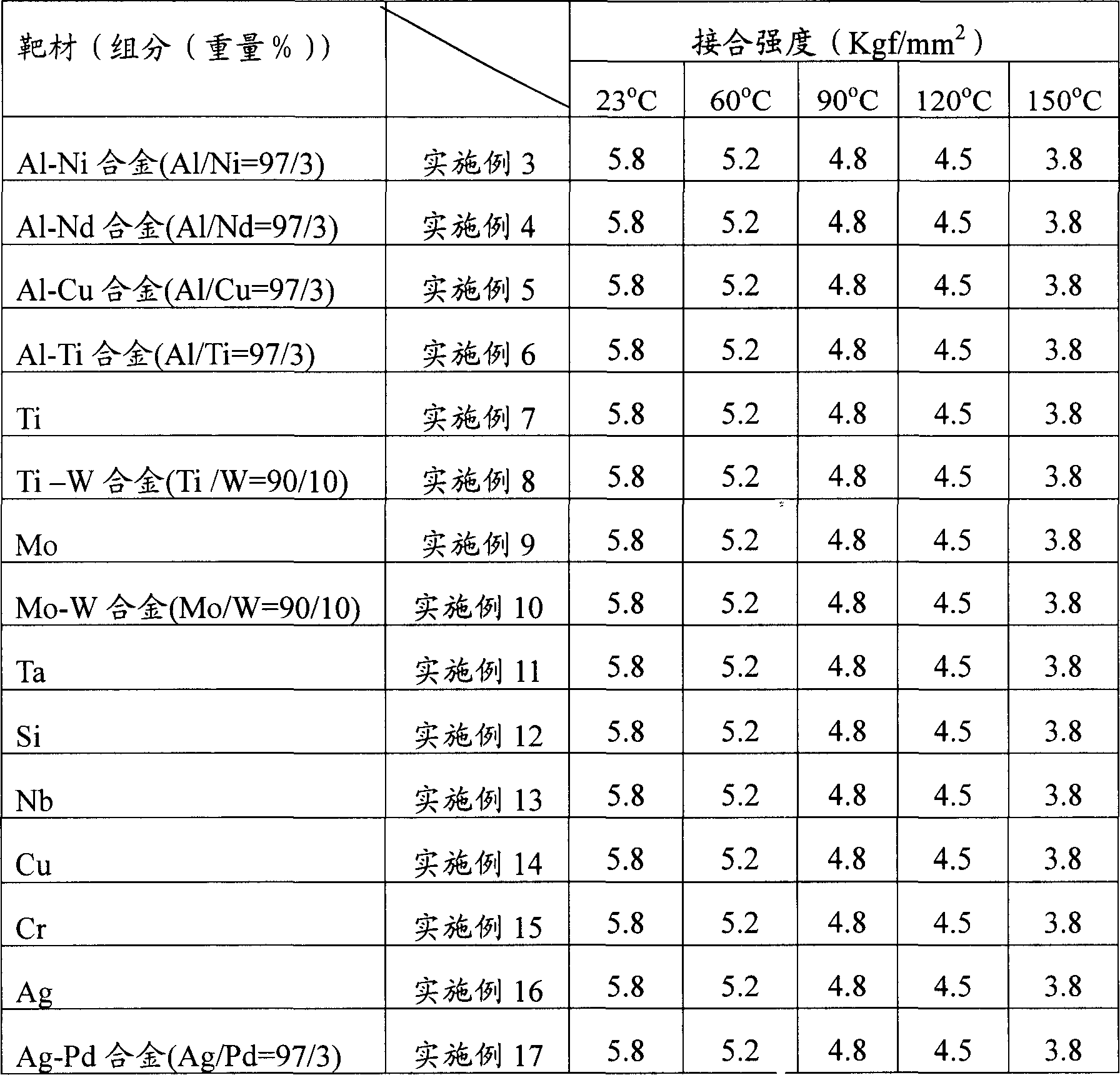

[0077] Using the sample No.2 (Sn / Zn (weight %)=91 / 9) welding alloy of the above-mentioned embodiment 2, various target materials (Al alloy, Ti, Ti alloy) , Mo, Mo alloy, Ta, Si, Nb, Cu, Cr, Ag, Ag alloy) and 20mm × 20mm × 5mm t Cu support plate, and then use the tensile test device automatic plotter AGS-500B (island Tsu Manufacturing Co., Ltd.), and the bonding strength was measured at room temperature (23° C.). In addition, while measuring the temperature near the joint with a thermocouple, it was heated with a Heating Gun (manufactured by Hakuko Co., Ltd.), and the joint strength at the time of temperature rise (60, 90, 120, and 150°C) was also measured. Determination.

[0078] The results are shown in Table 2.

[0079] In addition, the results of measuring the corrosion amount of each support plate (Cu) by the same method as in Example 2 were almost the same as those in Example 2.

[0080] Table 2

[0081]

[0082] As shown in Table 2, it was shown that the welding a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bond strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com