Method for preparing high conductive, high temperature electronic frame material

A frame material, special-shaped technology, applied in other manufacturing equipment/tools, furnace types, manufacturing tools, etc., can solve the problems of low product performance, low yield, complex process flow, etc., to achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

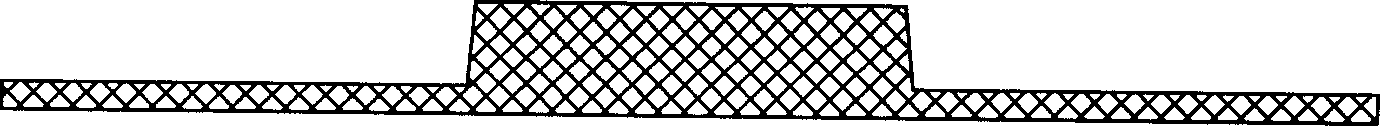

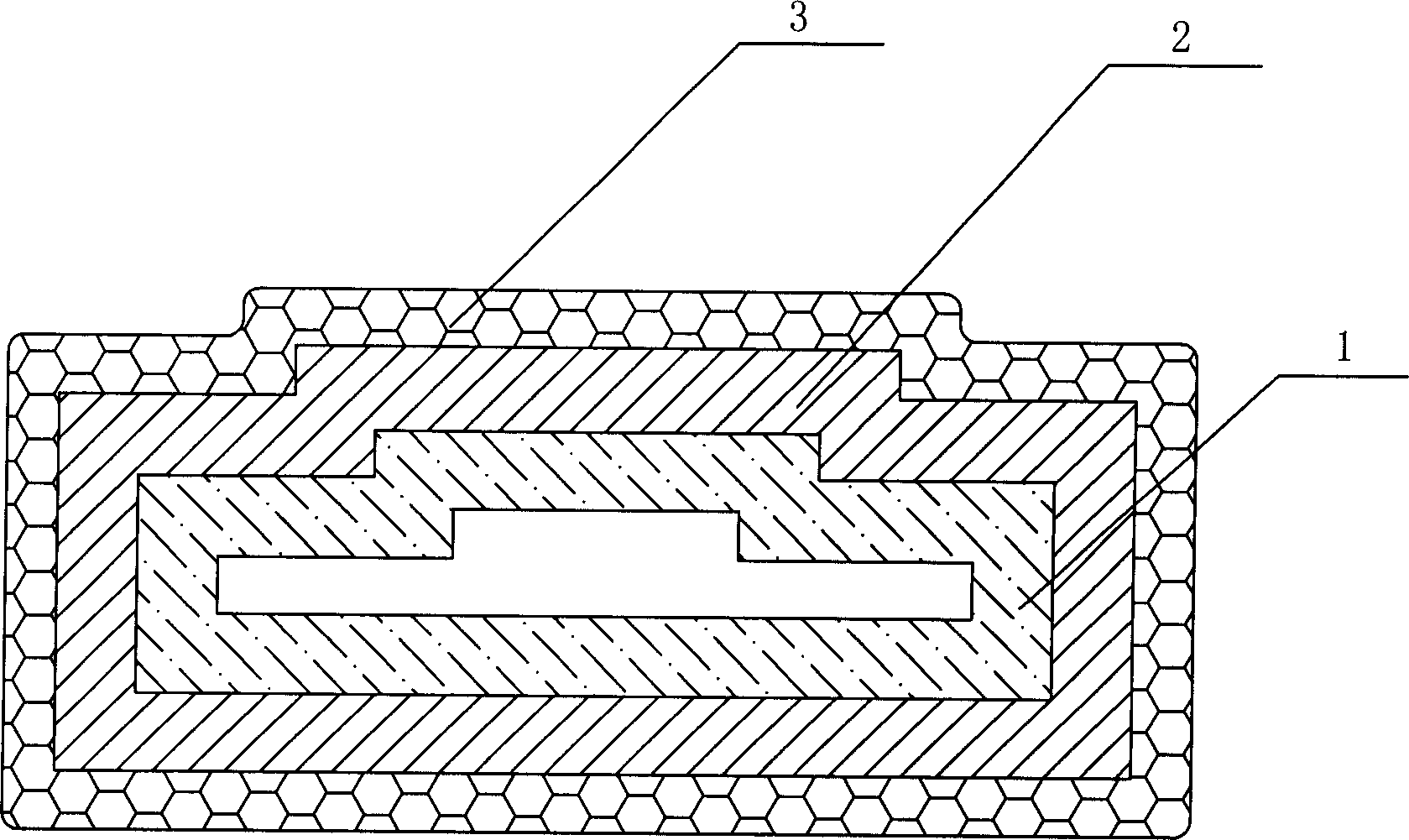

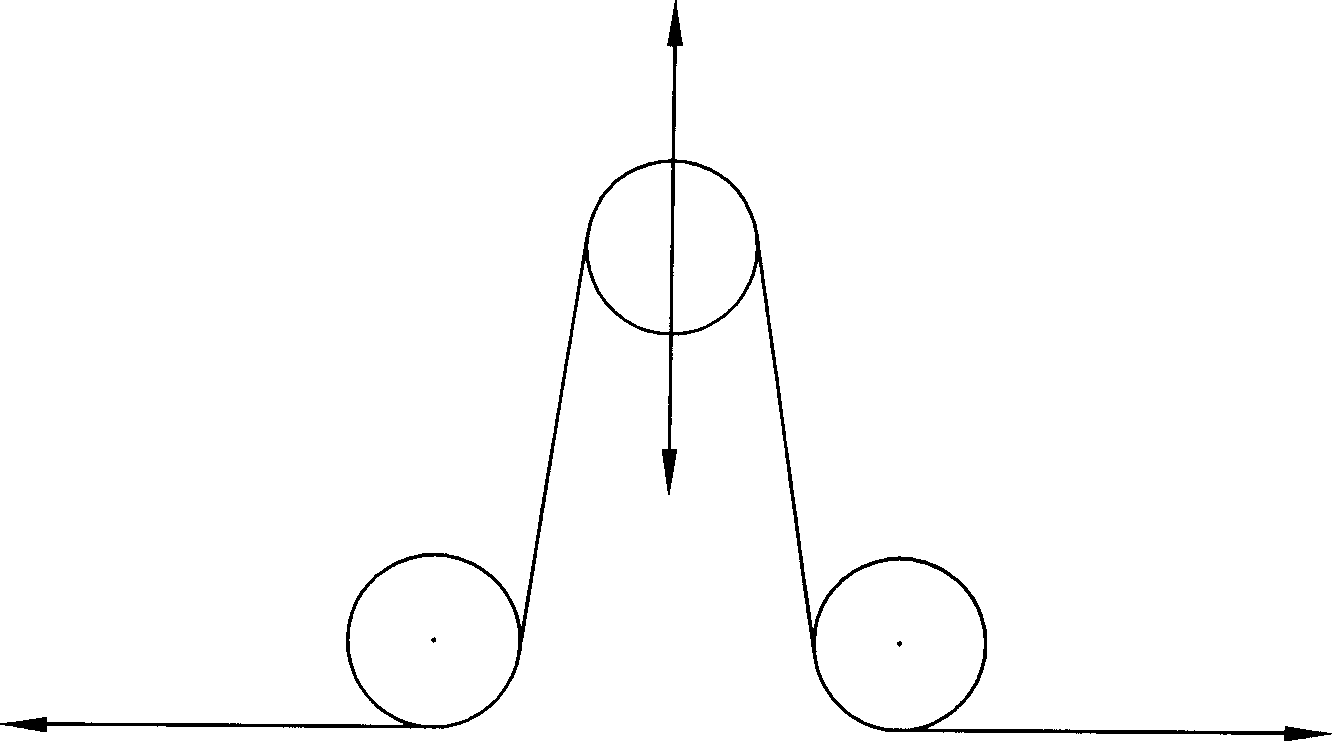

[0024] A method for preparing a high-conductivity, high-strength special-shaped electronic frame material, which is characterized in that it includes the following process steps: ① After melting the metal copper, the special-shaped crystallizer is used to directionally recrystallize through the directional solidification technology to produce unidirectional fiber crystal structure metal The material is used to prepare the billet, and the oxygen content is controlled during the smelting process. The mass percentage relative to the total metal material is ≤0.0005%. The billet is a small as-cast billet whose cross-sectional shape is basically similar to the product shape. The width dimension difference is ±10 %, the thickness difference is not more than 10 times the thickness of the cross-section of the finished product. The structure of the special-shaped cry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com