Tade calligraphy scripts and paintings and its making method

A production method, calligraphy and painting technology, applied in special decorative structures, specialized techniques of artistic painting, decorative arts, etc., can solve the problems of complex operation, high work intensity, poor decoration, etc. high-end effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

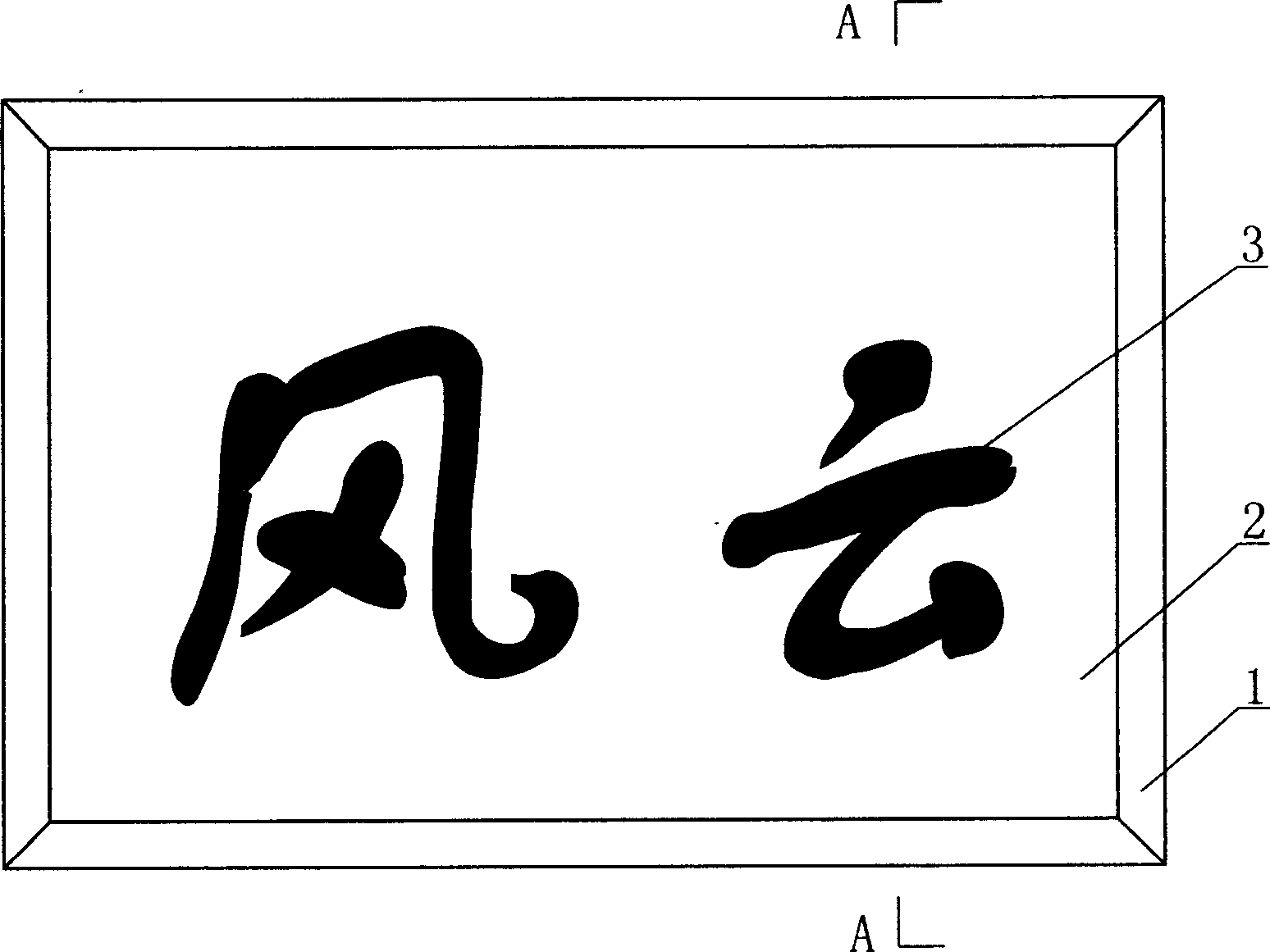

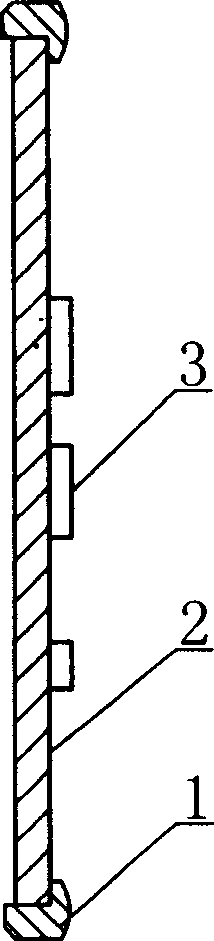

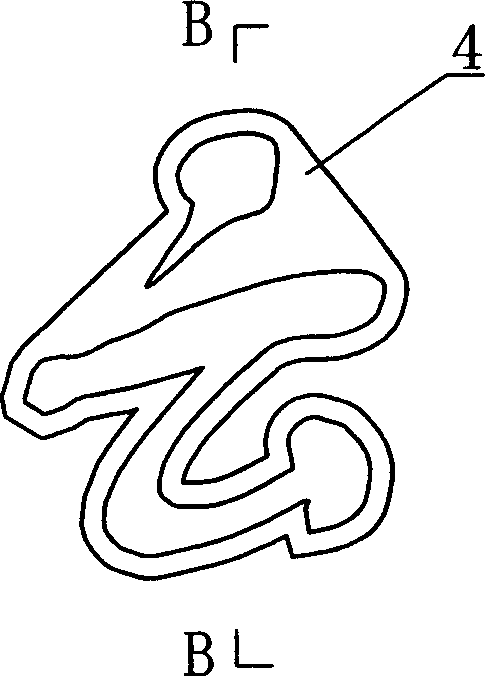

[0017] Such as Figure 1 to Figure 4 As shown, first use a computer engraving knife to carve raised calligraphy and paintings on PVC foam board or wooden board, then pour silica gel on the raised calligraphy and paintings, and after constant temperature and drying, make calligraphy and calligraphy mold 4, stand-by; Jade is pulverized to 100-1000 mesh by a pulverizer, according to the weight ratio of jade powder and resin glue of 2.5:1 to 1.5:1, the jade powder and resin glue are mixed evenly, and then poured into calligraphy and painting mold 4, and formed after natural drying , from the mold, and make the calligraphy and painting module 3; glue the back of the calligraphy and painting module 3, and then stick it on the decorative board 2;

Embodiment 2

[0019] Such as Figure 1 to Figure 4 As shown, first use a computer engraving knife to carve raised calligraphy and paintings on PVC foam board or wooden board, then pour silica gel on the raised calligraphy and paintings, and after constant temperature and drying, make calligraphy and calligraphy mold 4, stand-by; Jade is pulverized to 500-700 mesh by a pulverizer, according to the weight ratio of jade powder and resin glue 2:1, the jade powder and resin glue are mixed, poured into the calligraphy and painting mold 4, shaped after natural drying, and molded. Get the calligraphy and painting module 3; glue the back of the formed calligraphy and painting module 3, and then stick it on the decorative board 2, the decorative board 2 can be a frosted board; then install the decorative frame 1 on the edge of the decorative board 2.

Embodiment 3

[0021] Such as figure 1 , figure 2 with Figure 5 As shown, first use a computer engraving knife to carve raised calligraphy and paintings on PVC foam boards or wooden boards, then pour silica gel on the raised calligraphy and paintings, and after constant temperature and drying, make multiple pieces decomposed according to the calligraphy and painting patterns. Calligraphy and calligraphy mold 4 ( Figure 5 Take two calligraphy and painting molds as an example, but in reality it can be decomposed into three, four or more, and the number of calligraphy and painting molds after decomposition is not limited by this embodiment), and is for use; get jade Grinding to 100-1000 mesh by a pulverizer, according to the weight ratio of jade powder and resin glue 2.5:1~1.5:1, mixing jade powder and resin glue evenly, then pouring into calligraphy and painting mold 4, forming after natural drying, The calligraphy and painting module 3 is made by removing the mold; the back of the calli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com