Polypropylene graft copolymer, its production and use

A polypropylene graft and copolymer technology, applied in the field of polypropylene graft copolymer and its preparation and application, can solve the problems of many side reactions, harsh reaction conditions, low ionization efficiency, etc., to improve blending compatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, preparation polypropylene graft polystyrene copolymer

[0032] 1. Preparation of hydroxyl-containing polypropylene copolymer

[0033]Polymerization was carried out in a 250ml three-neck glass flask. First, vacuumize and pass the propylene gas. After repeating the above operation three times, the propylene gas is kept at 1MPa; 50mL of toluene is added to the reactor, and at 50°C, 2ml of a heptane solution of triisobutylaluminum (1.8mol / L), 2g boron-containing monoene monomer (m in formula II is 4), 3g of diphenyldimethoxysilane (DDS) and 0.1g Ziegler-Natta catalyst (titanium tetrachloride supported on magnesium chloride , wherein the Ti content is 3% of the total weight of the catalyst); the reaction was stirred at 50°C for 1 hour, after the polymerization reaction was completed, at 0°C, 30mL of 1.2g / mL hydrogen peroxide tetrahydrofuran solution and 10mL of 0.3g / mL hydrogen peroxide solution were added After the sodium aqueous solution, hydrolysis was ca...

Embodiment 2

[0039] Embodiment 2, preparation polypropylene graft polymethyl methacrylate copolymer

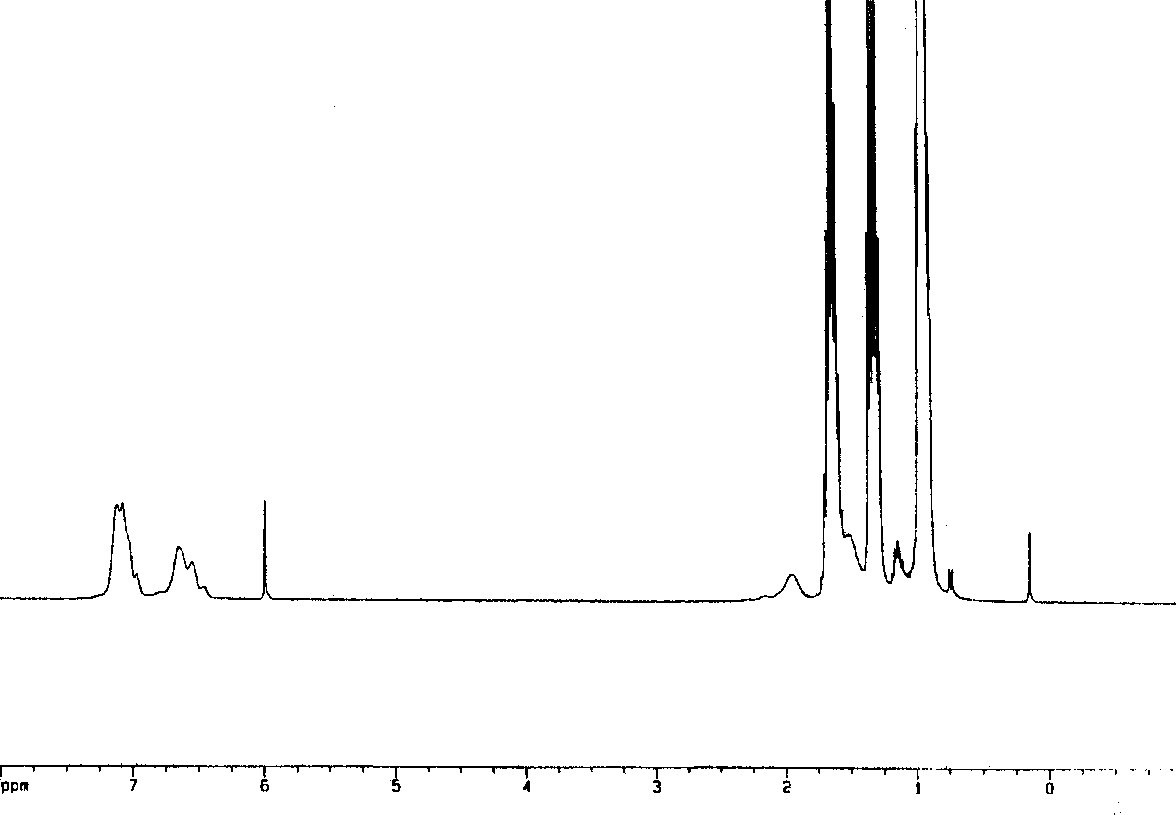

[0040] Take a 250ml three-necked flask, add 20.0g of the polypropylene-based atom transfer radical polymerization initiator obtained in Step 2 of Example 1, add 100ml of anisole, add 0.1g of cuprous chloride, and 0.05ml of pentamethyldiethylenetriamine , add 30g of methyl methacrylate, keep the reaction temperature at 95°C, react for 2 hours, precipitate with excess 10% hydrochloric acid ethanol, filter to obtain a white solid, fully wash with water and ethanol, and dry in vacuum to obtain polypropylene grafted polymer Methyl methacrylate copolymer 31.0g, its 1 H-NMR characterization as figure 2 , indicating that the structure of the obtained product is correct.

[0041] The copolymer had a number average molecular weight of 112600 g / mol (n=1352, k=558) and a molecular weight distribution of 4.56.

Embodiment 3

[0042] Embodiment 3, preparation polypropylene graft poly-p-methylstyrene copolymer

[0043] 1. Preparation of hydroxyl-containing polypropylene copolymer

[0044] Polymerization was carried out in a 250 mL three-neck glass flask. First, vacuumize and pass propylene gas. After repeating the above operation three times, keep the propylene gas at 1MPa; put 50ml of pentane into the reactor, and then add 1mL of triethylaluminum in heptane solution (1.8mol / L), 0.1g boron-containing monoene monomer (m in formula II is 4), 2g of diphenyldimethoxysilane (DDS) and 0.1g Ziegler-Natta catalyst (titanium tetrachloride supported on magnesium chloride above, where the Ti content is 3% of the total weight of the catalyst); stirring at 50°C for 1 hour; after the polymerization reaction, at 0°C, add 30mL 1.2g / mL hydrogen peroxide tetrahydrofuran solution and 10mL 0.3g / mL hydrogen peroxide After potassium aqueous solution, hydrolysis was carried out at 40° C. for 10 hours; then, a white soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com