Process for the desulfurization of hydrocarbonacecus oil

A hydrocarbon oil and hydrodesulfurization technology, which is applied in the treatment of hydrocarbon oil, petroleum industry, and only multi-stage series refining process, etc., can solve the problems of uneconomical and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

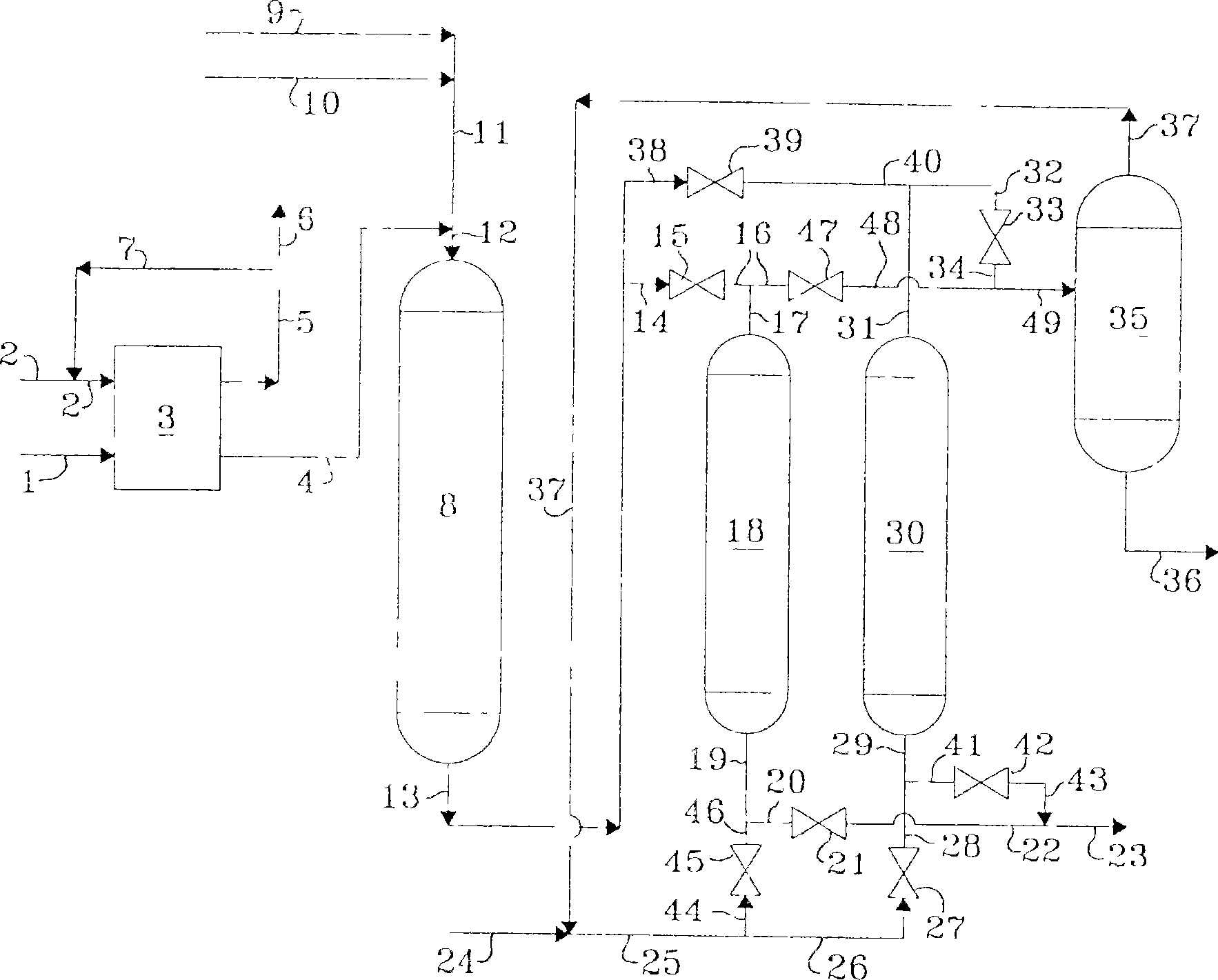

[0033] A stream of straight run vacuum gas oil boiling in the range of 315°C (600°F) to 482°C (900°F) containing 2 wt% sulfur is fed to a hydrodesulfurization zone containing a hydrodesulfurization catalyst comprising alumina, Nickel, Molybdenum and Phosphorus. At 11.8Mpa (1700psig) pressure, 843nm 3 / m 3 The hydrodesulfurization zone was operated at a hydrogen / feed ratio of (5000 SCFB), a maximum catalyst temperature of 393°C (740°F) to reduce the residual sulfur of the resulting desulfurized vacuum gas oil to 500 wppm (0.05 wt%). The desulfurized vacuum gas oil is then fed to an oxidation reaction zone where it is contacted with acetic acid and hydrogen peroxide in water. The molar feed ratio of hydrogen peroxide to sulfur was 5, and the molar ratio of acetic acid to hydrogen peroxide was 5. The contacting was performed at a temperature of 65°C (150°F) and a pressure of 207 kPa (30 psig). The effluent from the oxidation reaction zone is passed over a catalyst containing m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com