Method for preparing magnetic granule-attapulgite nano composite material

A nano-composite material and attapulgite technology, which is applied in the field of magnetic particle-attapulgite clay composite material preparation, can solve the problems of increased cost of flocculants, increased difficulty in sludge treatment, reduced adsorption effect of attapulgite clay, and the like, To achieve the effect of excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

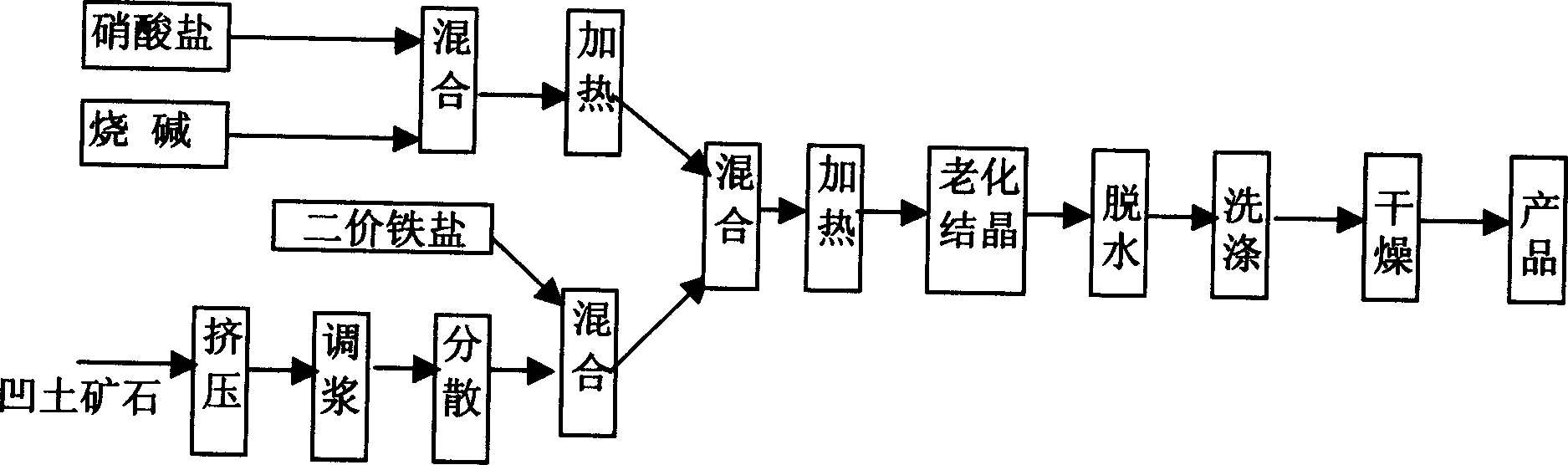

[0023] The specific implementation is as follows:

[0024] 1. The attapulgite clay and water that have been processed through extrusion and mud refining are made into an attapulgite clay suspension with a mass volume ratio of 0.1:100 to 20:100, preferably a solid-to-liquid ratio of 1:100 to 5:100, Stirring promotes the dispersion of attapulgite crystal bundles to form a stable attapulgite clay suspension;

[0025] 2. Under the condition of strong stirring, add divalent iron salt solution to the dispersed attapulgite clay suspension, the concentration of the iron salt solution is 1%-50%, preferably 5%-10%. The mass ratio of iron to attapulgite clay in the attapulgite clay and iron salt mixture is 100:0.5-100:30, preferably 100:1-100:5. The iron salt referred to includes ferrous sulfate, ferrous chloride, and ferric chloride. The above suspension is heated to 50°C to 100°C, preferably 60°C to 80°C.

[0026] 3. In addition, prepare a mixed solution of nitrate and lye, the conc...

Embodiment 2

[0031] The difference from the above-mentioned Example 1 is that in order to make the crystal particle size of the magnetic particles formed by direct crystallization from the solution smaller, 0.1% by weight of the attapulgite clay is added to the attapulgite clay suspension prepared in step 1. Citric acid, or citrate, or phosphate, as a crystal growth control agent. Other steps are the same as in Example 1. Finally, the particle size of the magnetic particles loaded on the surface of the attapulgite is less than 15 nanometers ( Figure 4 shown).

Embodiment 3

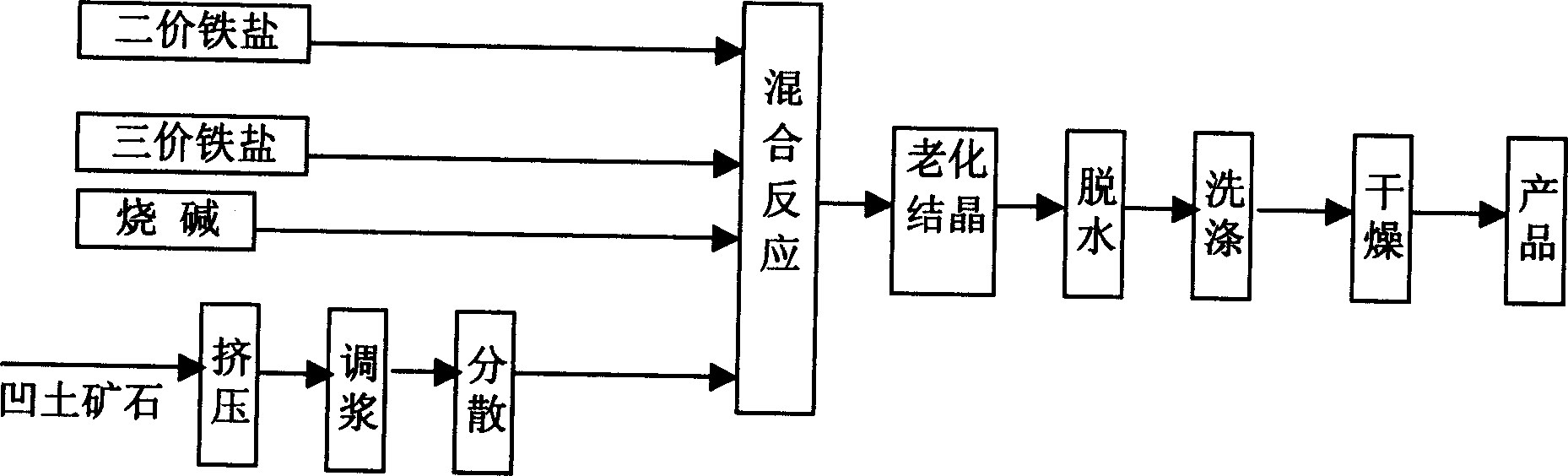

[0033] The specific implementation is as follows:

[0034] 1. The attapulgite clay and water that have been processed through extrusion and mud refining are made into an attapulgite clay suspension with a mass volume ratio of 0.1:100 to 20:100, preferably a solid-to-liquid ratio of 1:100 to 5:100, Stirring promotes the dispersion of attapulgite crystal bundles to form a stable attapulgite clay suspension;

[0035] 2. Add the mixed solution of ferrous iron salt and ferric iron salt to the dispersed attapulgite clay suspension under strong stirring condition. The molar ratio of ferrous salt to ferric salt is 3:1~1:1, preferably 1:1;

[0036]3. Add lye to the above suspension under vigorous stirring, the molar ratio of lye to iron salt is 8:3, stir and age the crystal for 0.5-5 hours.

[0037] 4. Dehydrating, washing and drying the suspension obtained in the above steps to obtain a magnetic particle-attapulgite clay composite material. The magnetic susceptibility of the obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com