Granite step gauge measuring device

A measuring device, granite technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of easy rust, inconvenient operation, temperature deformation, etc., and achieve the effect of high measurement accuracy, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

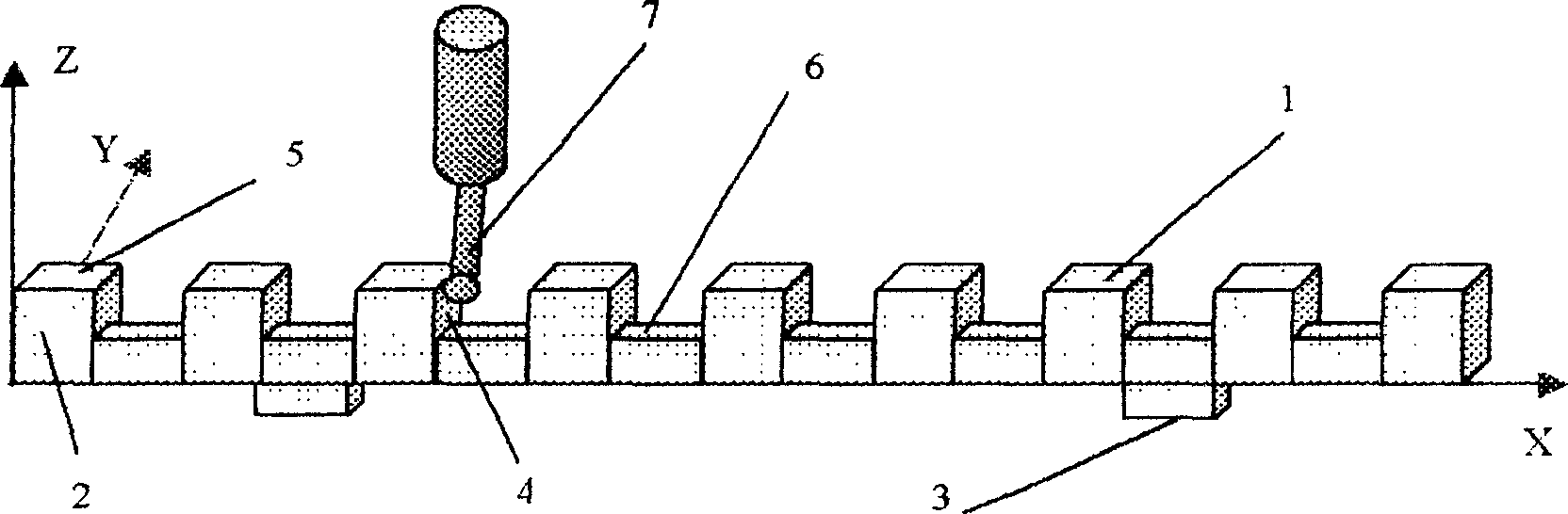

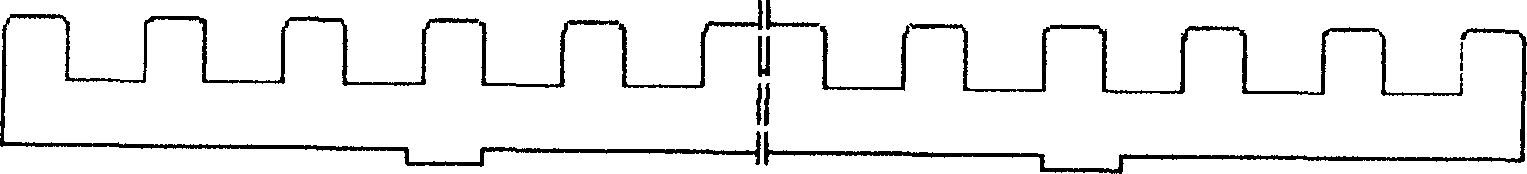

[0011] Such as figure 1 , 2 Shown in , 3, the granite step distance gauge that granite (marble) is made. Granite is made from high-quality underground rock layers. After hundreds of millions of years of natural aging, the shape is extremely stable, and there is no need to worry about deformation due to conventional temperature differences. The general steel line expansion coefficient is 1.17×10 -5 / ℃, cast iron is 1.0×10 -5 / ℃, copper is 1.7×10 -5 / °C. That is to say, when the temperature rises by 1°C, a 1-meter-long steel will elongate by 11.7 μm, a 1-meter-long cast iron will elongate by 10.0 μm, and a 1-meter-long copper will elongate by 17.0 μm. If the above materials are used as standard parts to measure the error of the machine tool, there will undoubtedly be a large measurement error. The granite material selected through rigorous physical tests has fine crystallization, hard texture, compressive strength of 2290-3750 kg / cm2, and hardness of Ta Mok's hardness of 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com