Discharge plate of automatic mill

A self-grinding machine and dustpan technology, which is applied in the field of self-grinding machine discharge dustpan board, can solve the problems of waste, increase product production cost, reduce production efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

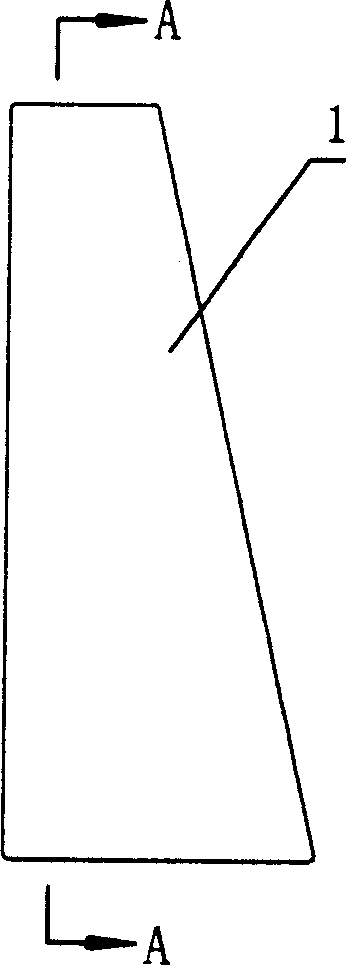

[0014] refer to Figure 4 , a number of dustpan plates 1 are arranged circumferentially on one side of the discharge end of the self-grinding machine grinding cylinder 2, and in the direction along the direction of quartz sand conveyance, a dustpan plate 1 is located upstream of the self-grinding quartz sand particles. The grid plate 3 for screening is located downstream of the dustpan plate 1 and is provided with a discharge cylinder 4 that can discharge the quartz sand particles conveyed by the dustpan plate 1 from the mill. The sand is re-transported back to the self-returning sieve in the grinding cylinder 2 of the self-mill. Because the quartz sand particles in the grinding cylinder 2 of the self-grinding machine continuously enter the dustpan plate 1 after being screened by the grid plate 3, and are transported to the discharge cylinder 4 through the dustpan plate 1, so the dustpan plate 1 will frequently interact with the quartz sand particles. Therefore, the dustpan b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com