Organic electroluminescence display unit

An electroluminescence and organic technology, applied in the field of active organic electroluminescence displays, can solve the problems of the influence of the performance of the organic electroluminescence diode 80, the reduction of the aperture ratio of the unit pixel 70, and the hindering of the display performance of the display.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

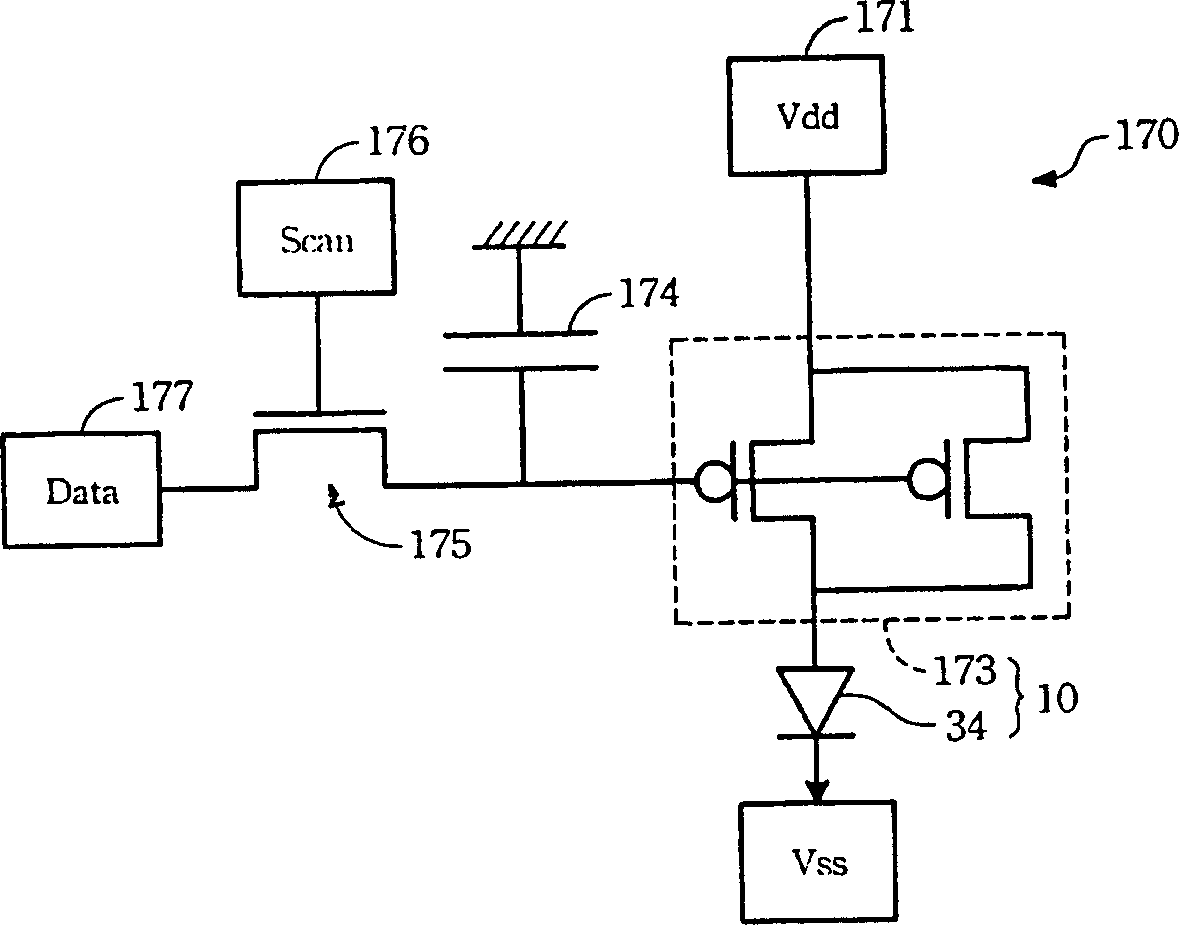

[0039] Please refer to figure 2 , which is an equivalent circuit diagram of the unit pixel 170 in the active organic electroluminescence display provided by the present invention. The unit pixel 170 includes the organic electroluminescence display unit 10 , a capacitor 174 and a second thin film transistor 175 . The organic electroluminescent display unit 10 includes an organic electroluminescent diode 34 and a first thin film transistor 173 . It is worth mentioning that the first thin film transistor 173 provided by the present invention is a thin film transistor with a double channel, which is compared with the traditional thin film transistor (of course, under the premise of other process conditions being the same) , the first thin transistor 173 of the present invention can generally provide twice the amount of current, so on the equivalent circuit diagram, this characteristic is represented by the symbol of two transistors connected in parallel.

[0040] During operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com