Precursor for fabricating nb*sn superconducting wire, and nb*sn superconducting wire, and method for fabricating the same

A technology of superconducting wires and precursors, which is applied in the manufacture/processing of superconductor devices, superconducting/high-conducting conductors, superconducting devices, etc. It can solve the problems of unsatisfactory high magnetic field properties, decreased crystallinity, and small thickness of Sn layer, etc. problem, to achieve the effect of preventing interruption and Sn leakage, uniform processing, and good superconducting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Ta powder and Sn powder having a size of 350 mesh (grain size of 40 μm or less) were mixed so as to satisfy an atomic ratio of Ta:Sn=6:5, and 2% by mass of Cu powder was added, followed by further mixing. The resulting mixture was placed in an aluminum pot, and heat-treated at 950° C. for 10 hours under a vacuum of 0.01 Pa. The heat-treated mixture was pulverized, placed again in an aluminum pot, heat-treated at 950° C. for 10 hours under a vacuum of 0.01 Pa, and then formed into Ta-Sn-Cu alloy powder having a particle size of 100 μm or less by crushing.

[0031] The obtained alloy powder was charged into a tube having an outer diameter of 17 mm and an inner diameter of 11 mm made of a Ta alloy of 7.5% by mass Nb having different contents of oxygen, nitrogen and carbon gas components or different crystal size. For all the samples, the hydrogen concentration was also measured, and the result was 5 ppm or less, which has no influence on the result. Those with a small av...

Embodiment 2

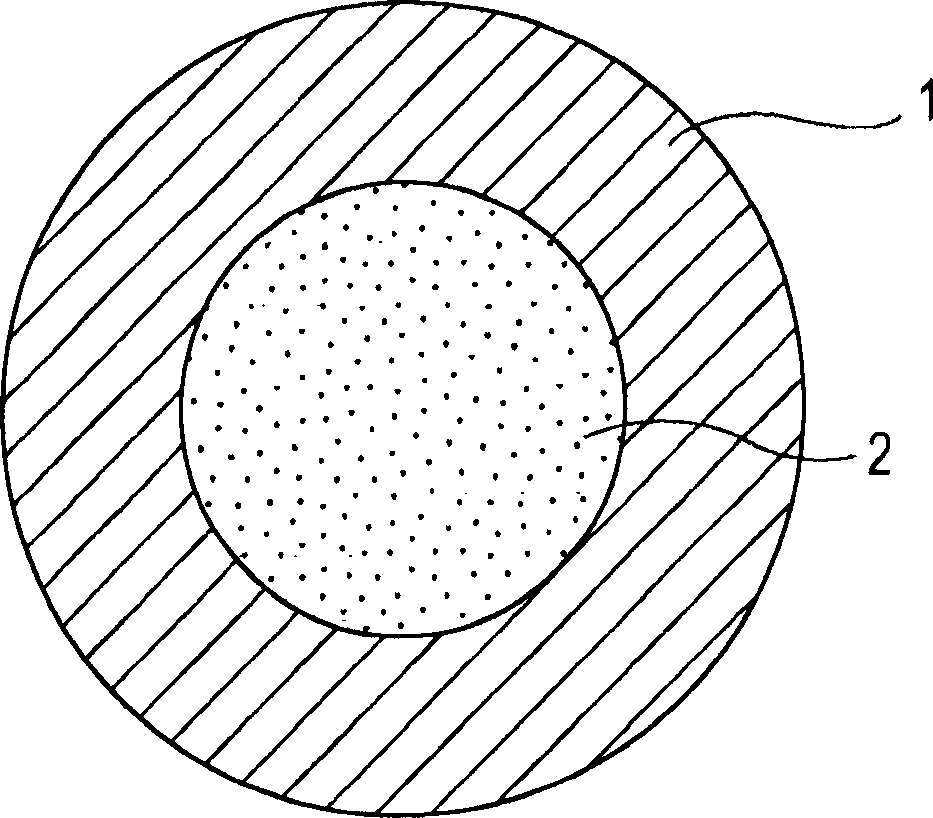

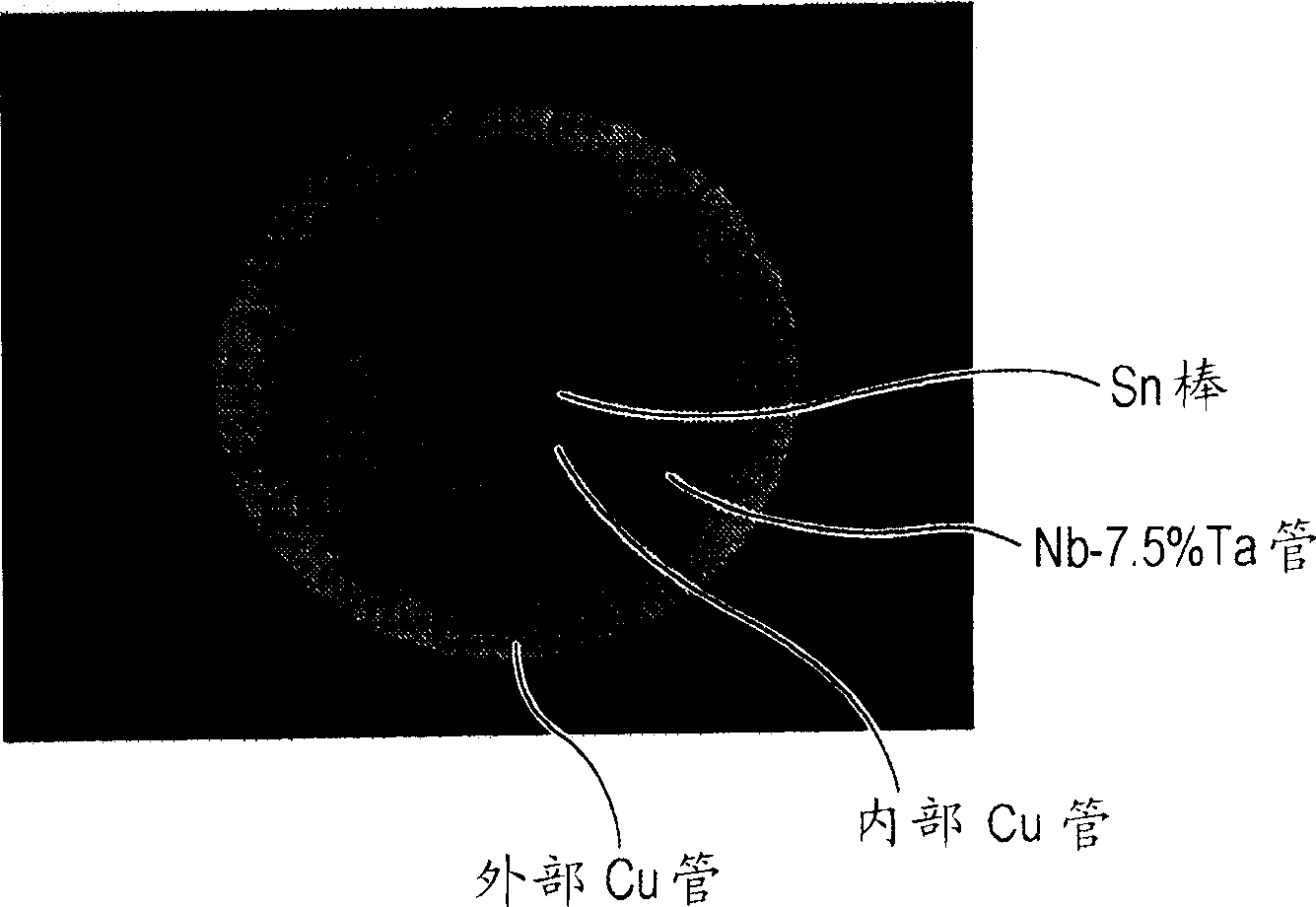

[0044] In each tube having an outer diameter of 55 mm and an inner diameter of 30 mm made of a Ta alloy of 7.5% by mass Nb, wherein the alloy has different concentrations of oxygen, nitrogen and carbon gas components and a different average grain size, A Cu tube with an outer diameter of 30 mm and an inner diameter of 26 mm was inserted, and a Sn rod with an outer diameter of 26 mm was further inserted. The Nb—Ta alloy tube was covered with a Cu tube having an outer diameter of 67 mm to form an extruded billet, which was extruded at room temperature to obtain an outer diameter of 28 mm. Subsequently, the outer diameter was reduced to 0.3 mm by wire drawing using a die.

[0045] Each filament was heat-treated at 700°C for 80 hours under vacuum. For the obtained wire, wire drawing results and critical current (Ic) in high magnetic field (external magnetic field: 21T), liquid helium (temperature: 4.2K) were measured. The Ic value was divided by the area of the non-copper port...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com