Method and apparatus for perforating printed circuit board

A technology for printed circuit boards and punching devices, which is applied in the direction of printed circuit manufacturing, printed circuits, electrical components, etc., can solve the problems of not being able to realize the high density of printed circuit boards, and achieve the improvement of SN ratio and increase Processing efficiency, high-quality processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

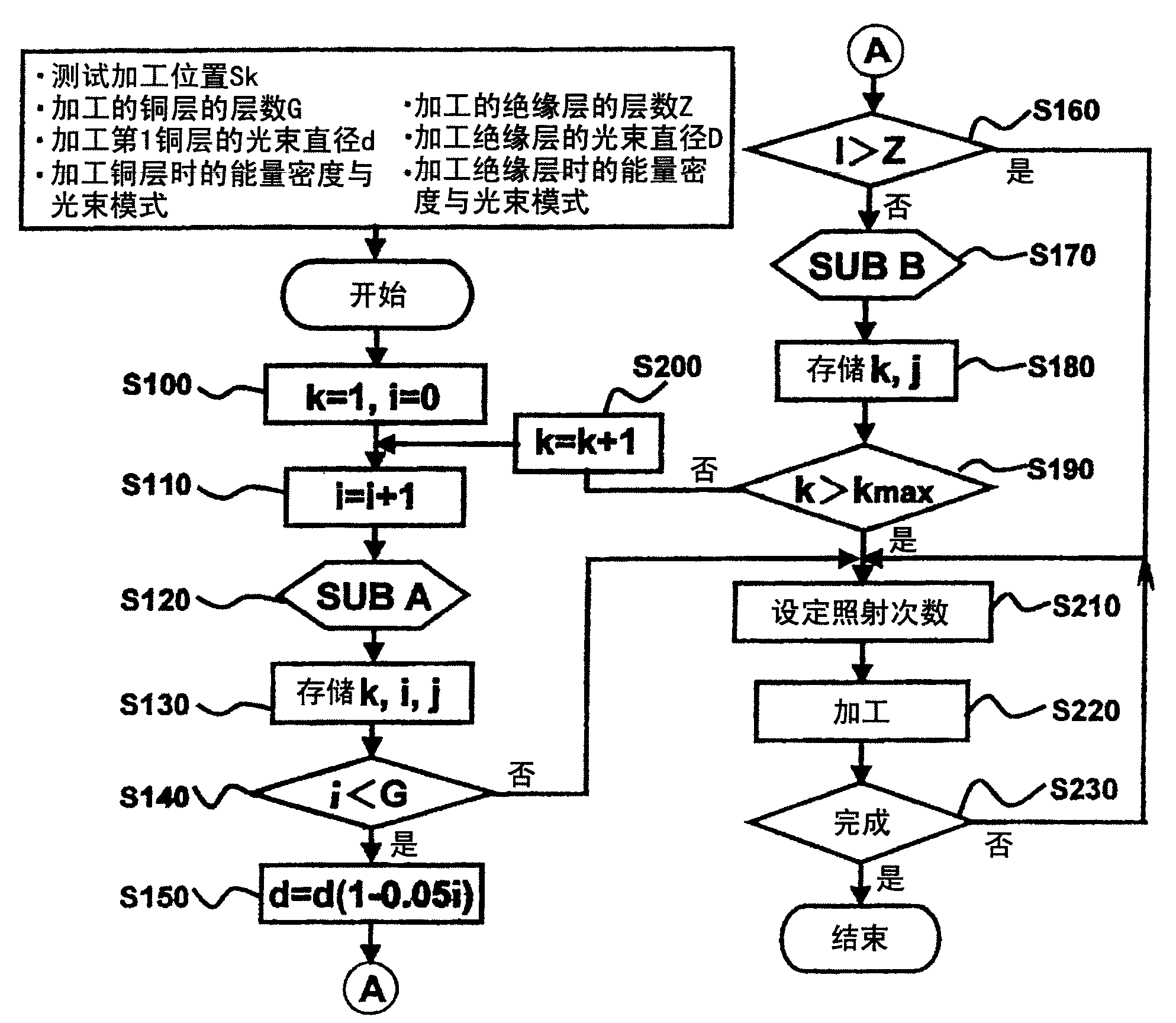

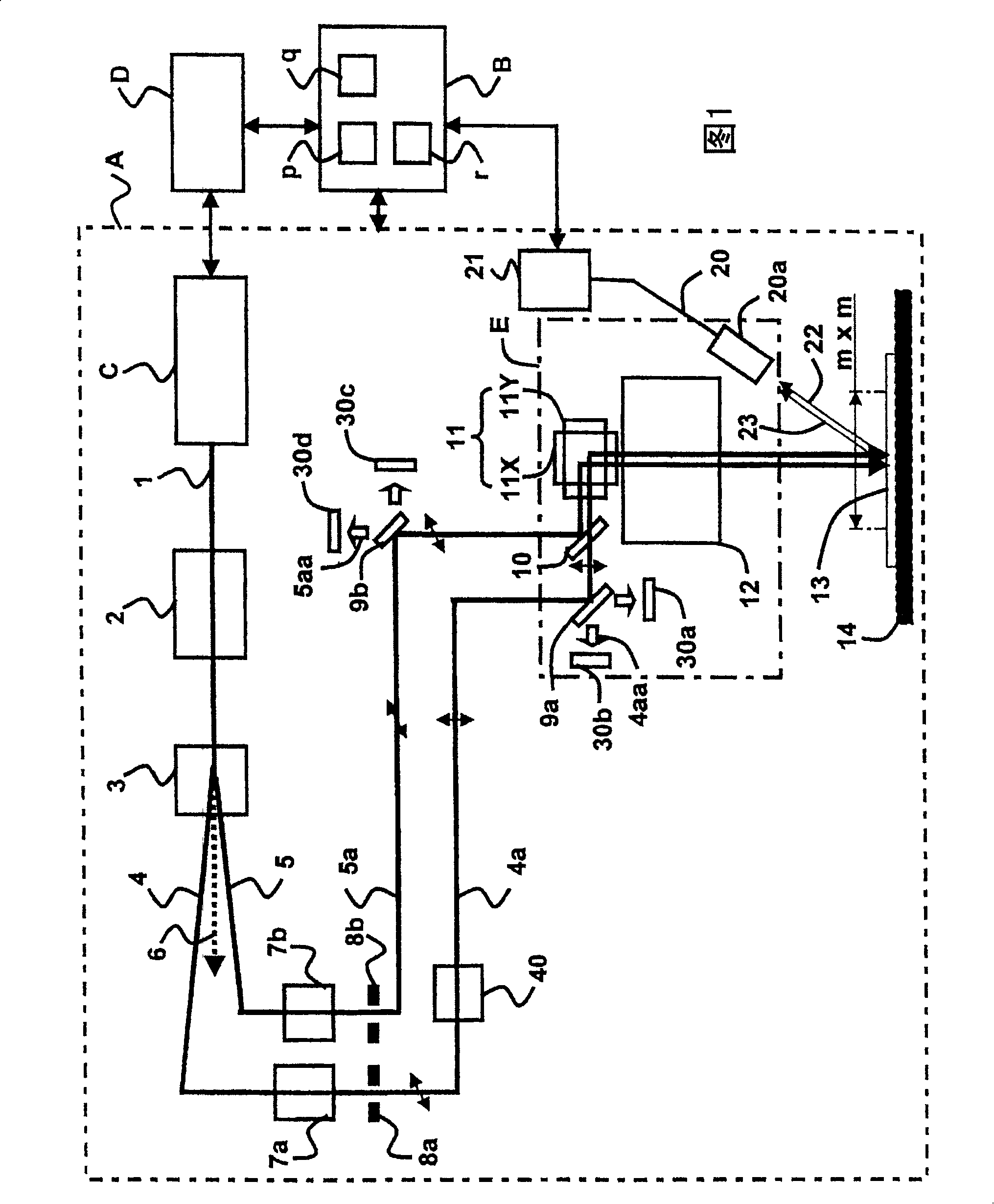

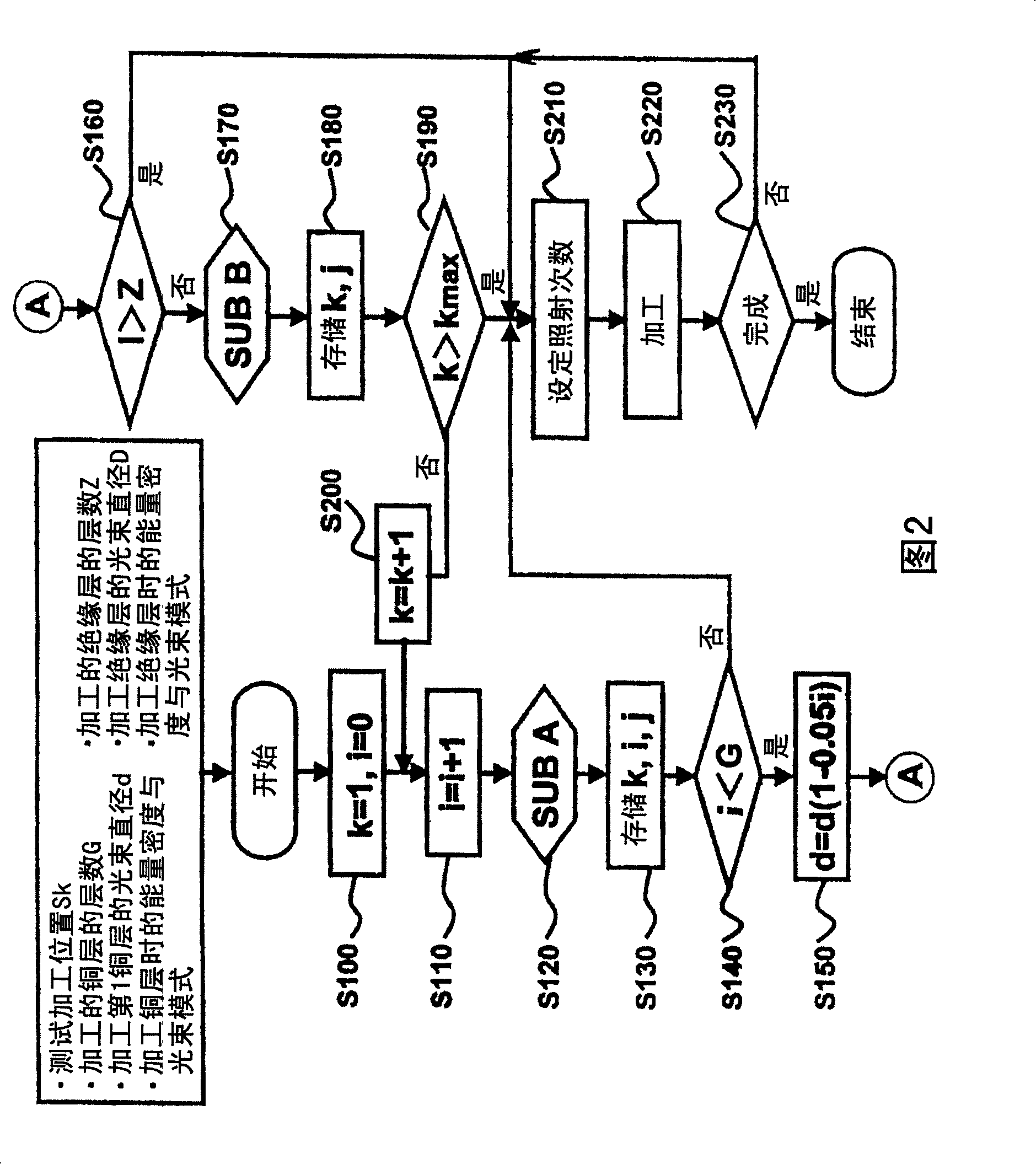

[0044] Fig. 1 is a block diagram of a printed circuit board punching device according to a first embodiment of the present invention.

[0045] The system controller B is connected to the device mechanism unit A, the laser oscillator controller D, and the optical sensor 21 indicated by dotted lines. As will be described later, the system controller B has a comparison unit p that compares the output of the photosensor 21 and photosensors 30a to 30d with a predetermined threshold value, a counter q that counts the number of times the laser beam irradiates the processing part before the comparison unit p operates, and Storage unit r for storing processing conditions and counted number of irradiations.

[0046] The energy density suitable for processing copper and the energy density suitable for processing insulators are prestored in the storage unit r. In addition, in the storage unit r, for each laser mode (energy distribution on a cross section perpendicular to the optical axis...

Embodiment 2

[0122]Here, when the intensity of the reflected light 22 incident on the optical sensor 30b is small, the detection accuracy may decrease.

[0123] Next, a modified example of the present invention will be described.

[0124] Fig. 6 is a front view of the vicinity of a machining head in a modified example (second embodiment) according to the present invention.

[0125] A 1 / 4λ plate 60 is disposed on the printed circuit board 13 side of the condenser lens 12 .

[0126] The 1 / 4λ plate 60 has a characteristic of outputting incident linearly polarized light as circularly polarized light and outputting incident circularly polarized light as linearly polarized light. Also, when the circularly polarized light is reflected by, for example, a mirror, the polarization direction of the reflected circularly polarized light is reversed, that is, the rotation direction changes by 180 degrees. Therefore, when the circularly polarized light whose rotation direction is reversed enters the 1 / ...

Embodiment 3

[0141] 7 is a block diagram showing a schematic configuration of a laser processing apparatus according to a third embodiment of the present invention. In this figure, in the laser processing apparatus according to this embodiment, the processing machine control unit 101 has a positioning control unit 103 for controlling the positioning of a printed circuit board 111 mounted on an X-Y table 112 and a control unit for controlling the irradiation circuit board 111. Laser control section 102 for laser beam 105 . A laser oscillator 104 is connected to the laser control unit 102 , and the laser oscillator 104 emits a laser beam 105 based on an instruction from the laser control unit 102 .

[0142] A mask 106 is disposed below the laser oscillator 104 , and a polarizing beam splitter 107 is disposed further below the mask. The laser beam 105 emitted by the laser oscillator 104 enters the polarized beam splitter 107 through the mask 106 . The polarizing beam splitter 107 is arrange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com