Process for preparing mixed garnet base ceramic material

A ceramic material and garnet-based technology, which is applied in the field of preparation of mixed garnet-based ceramic materials, can solve the problems of low YAG yield, quenching of Nd luminescence concentration, and difficulty in finding materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

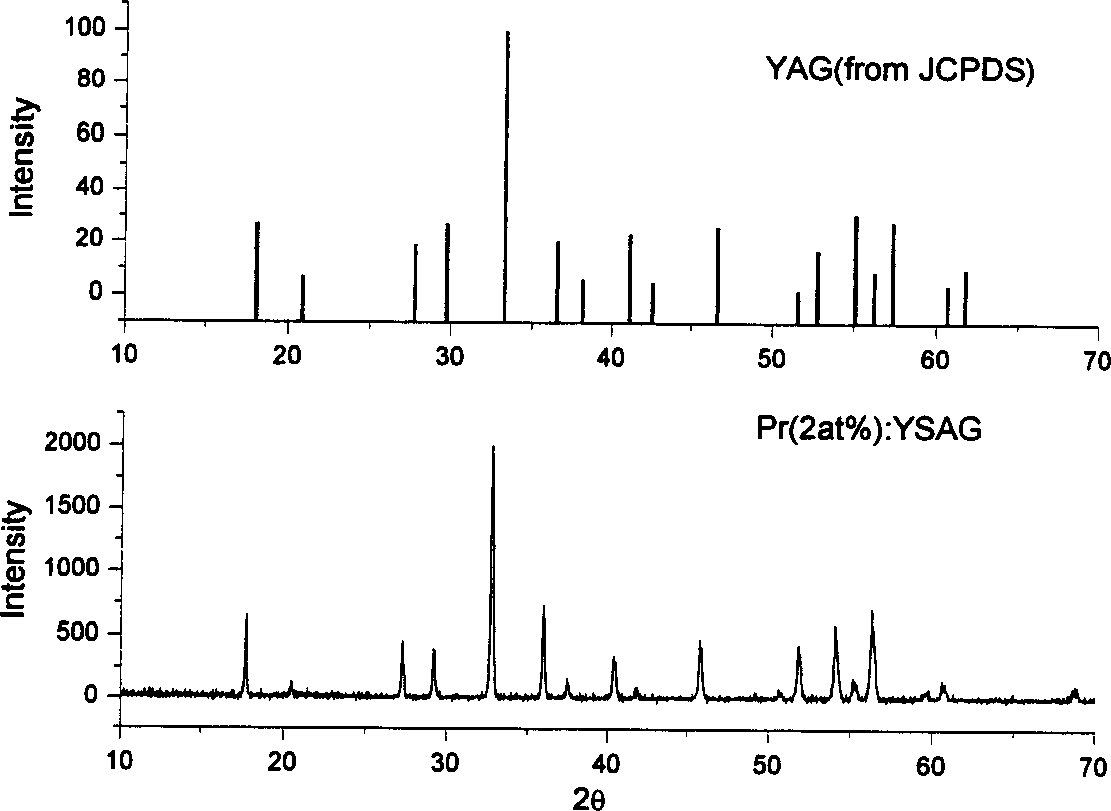

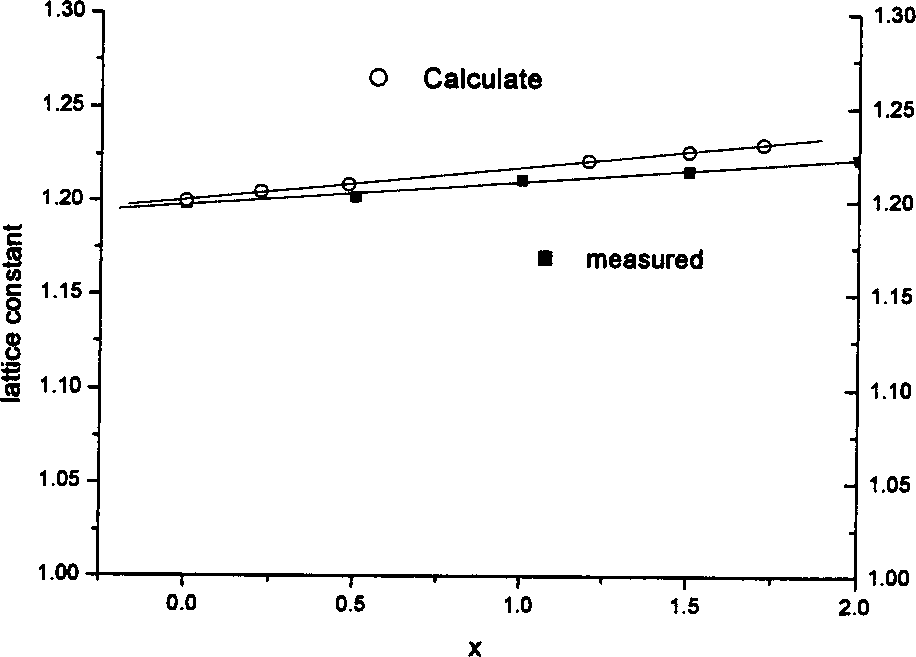

Image

Examples

Embodiment 1

[0027] Nd:Y 3 sc x Al (5-x) o 12 Preparation of mixed garnet transparent ceramics: Dissolve Y, Al, Sc, Nd nitrates in water to form a solution containing the required elements, and dilute to about 0.1mol / L with distilled water. Add ammonia water of sufficient concentration to this mixed solution under stirring, adjust the pH value to 7-8, stir to form a precursor of precipitation, and as a by-product of precipitation, stir this mixture for about 30 minutes until basically dissolved Y, Al, Sc, Nd are all precipitated out. The mixed solution was then washed with distilled water to remove by-products. Then dry in an oven for 8 hours to obtain the precursor of the desired powder. The calcination temperature is generally at 900°C and the time is 2 hours. After calcination, the desired oxide powder is obtained.

[0028] The oxide powder is pressed into blocks by dry pressing or balanced heating and pressing to increase the density of the green body. Mold materials should be ...

Embodiment 2

[0030] Ce:Lu 3 sc x Al (5-x) o 12 Preparation of mixed garnet transparent ceramics: Dissolve Lu, Al, Sc and Ce nitrates in water to form a nitrate solution in which required elements are dissolved, and filter to remove insoluble substances. Then add a certain amount of glycine to the solution, and heat at 100°C until the water is evaporated to dryness to obtain a transparent gel-like substance. Then transfer it to a muffle furnace at 500°C, the gelatinous substance will burn quickly and emit brown smoke. A brown powder remained. Then calcined at 1000° C. for 2 hours to prepare the oxide powder of the desired composition.

[0031] The oxide powder is pressed into blocks by dry pressing or balanced heating and pressing to increase the density of the green body. The green body is at 200Kg / cm 2 It is pressed and formed under the pressure, and after dry pressing, it is subjected to isostatic pressing (2000Kg / cm 2 ) treatment to further increase the density of the green body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com