Compressed high-temperature packer with gas propelling

A packer and compression technology, applied in sealing/isolation, wellbore/well parts, earthwork drilling and production, etc., can solve problems such as unreasonable structure, easy to lose parts, low sealing success rate, etc., to improve Timely operation, reasonable design and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

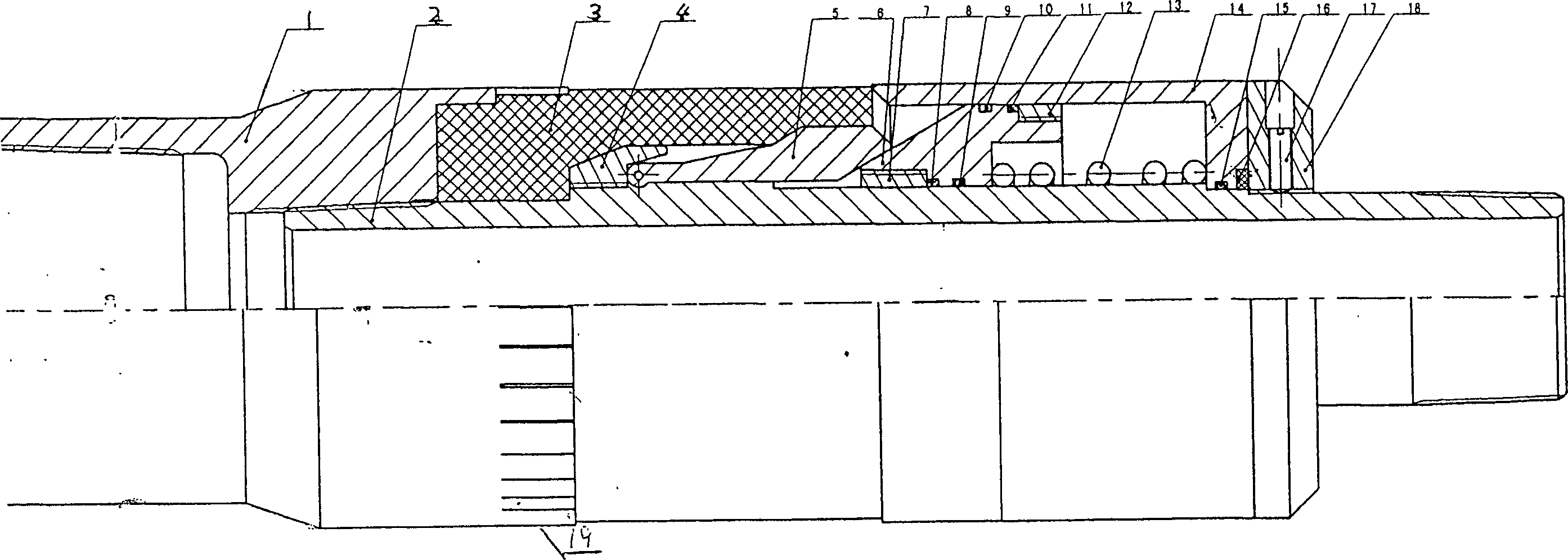

[0016] The present invention is provided by the following embodiments, and the present invention will be further described below in conjunction with the accompanying drawings.

[0017] In the figure, the upper joint 1 is connected with the upper thread of the central tube. The material of the upper joint 1 is 35CrMo. 7 / 8 "TBG buckle, with 15-20° arc on the outer edge, the central tube 2 is made of 35CrMo, and its upper and lower ends are respectively equipped with 2 7 / 8 "TBG buckle, the side wall is equipped with a rubber tube 3 from left to right, the outer layer of the rubber tube 3 is a protective seat 19, the rubber tube is set in the protective seat during assembly, and 32 sawn grooves are evenly distributed on the protective seat 19 , the groove width is 14.7 mm, the groove depth is 20 mm, and the center angle between each saw kerf groove is 11.25 degrees. Ring 4 and supporting claw 5, the outer circumference of the control ring 4 is in contact with the inner surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com