Continuouslly-casting electroslag furnace

An electroslag furnace and continuous casting technology, which is applied in the field of metal electroslag remelting equipment, can solve the problems of large head and tail removal of steel ingots, large carbide size, and affecting steel quality, so as to shorten the production cycle and improve production efficiency , the effect of low radiation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

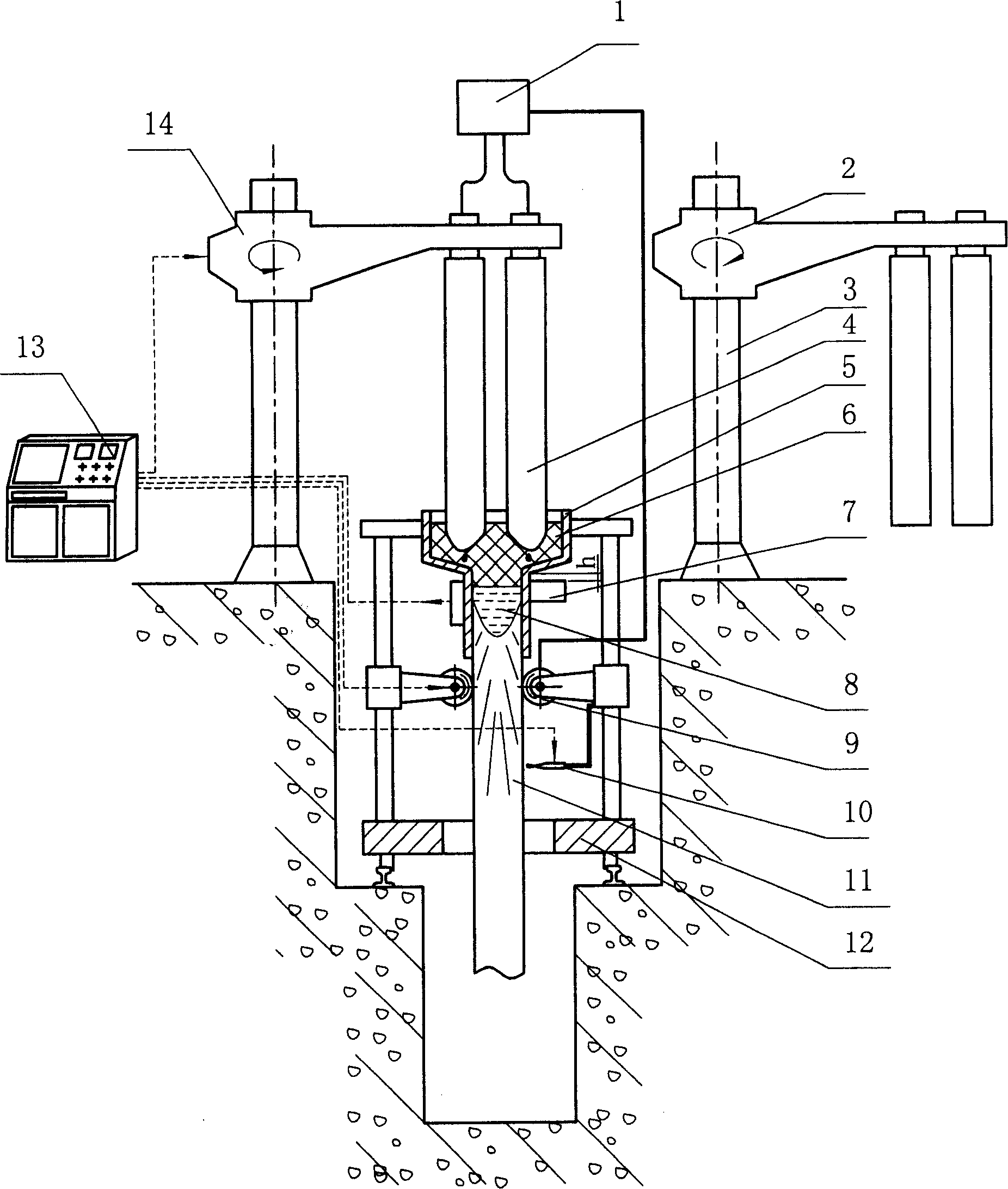

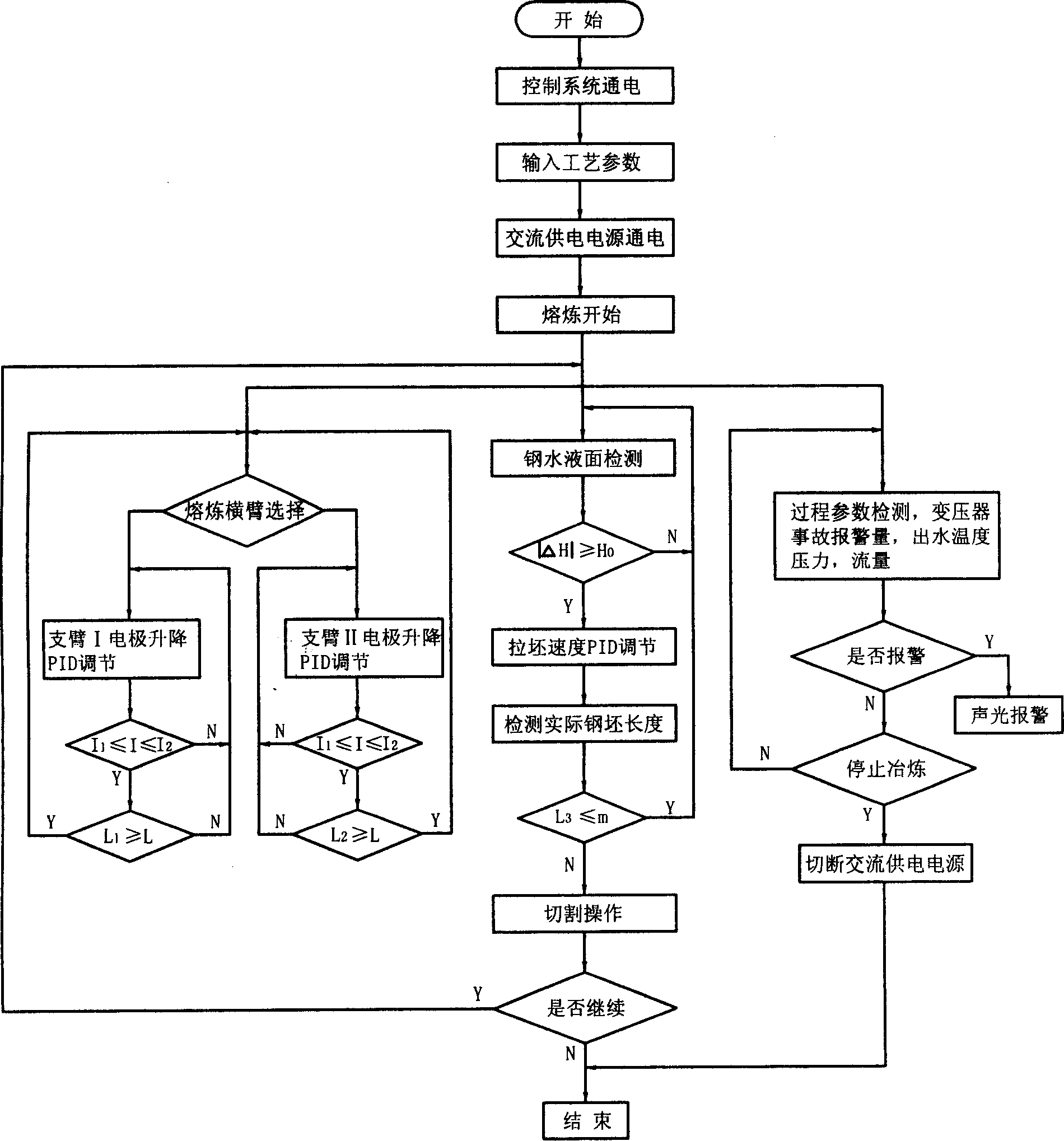

[0037] Embodiment 1: as figure 1 As shown, the present invention includes an AC power supply 1, an electrode lifting mechanism, an electrode 4, a crystallizer 5 and its supporting mechanism 12, a molten steel level detection device 7, a casting mechanism 9, a cutting device 10 and a control system 13, and an electrode lifting mechanism Including the cross arm and column 3, the electrode 4 is bipolar in series, and one end of the two electrodes is respectively fixed on the cross arm of the electrode lifting mechanism, and is respectively connected to the power supply 1 through cables, and the other end is placed inside the crystallizer 5, and the electrode 4 Melt at the top of the crystallizer 5 and solidify at its bottom; the crystallizer 5 is a T-shaped water-cooled crystallizer, the top of which is cylindrical, and the bottom is a square tube, and a support mechanism 12 is fixed around the crystallizer 5. Molten steel liquid level detection device 7 is installed in the trans...

Embodiment 2

[0055] Embodiment 2: as figure 1 As shown, the present invention includes an AC power supply 1, an electrode lifting mechanism, an electrode 4, a crystallizer 5 and its supporting mechanism 12, a molten steel level detection device 7, a casting mechanism 9, a cutting device 10 and a control system 13, and an electrode lifting mechanism Including the cross arm and column 3, the electrode 4 is bipolar in series, and one end of the two electrodes is respectively fixed on the cross arm of the electrode lifting mechanism, and is respectively connected to the power supply 1 through cables, and the other end is placed inside the crystallizer 5, and the electrode 4 While the upper part of the crystallizer 5 is melting, it is solidified at its lower part; the crystallizer 5 is a T-shaped water-cooled copper crystallizer, and its upper and lower parts are square cylinders, and a supporting mechanism 12 is fixed around the crystallizer 5. The small section of the device 5 is equipped wit...

Embodiment 3

[0056] Embodiment 3: as figure 1 As shown, the present invention includes an AC power supply 1, an electrode lifting mechanism, an electrode 4, a crystallizer 5 and its supporting mechanism 12, a molten steel level detection device 7, a casting mechanism 9, a cutting device 10 and a control system 13, and an electrode lifting mechanism Including the cross arm and column 3, the electrode 4 is bipolar in series, and one end of the two electrodes is respectively fixed on the cross arm of the electrode lifting mechanism, and is respectively connected to the power supply 1 through cables, and the other end is placed inside the crystallizer 5, and the electrode 4 Melt at the top of the crystallizer 5 and solidify at its lower part; the crystallizer 5 is a T-shaped water-cooled copper crystallizer, and its upper and lower parts are cylindrical, and a supporting mechanism 12 is fixed around the crystallizer 5. The small section of the device 5 is equipped with a molten steel level det...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com