Electric connector

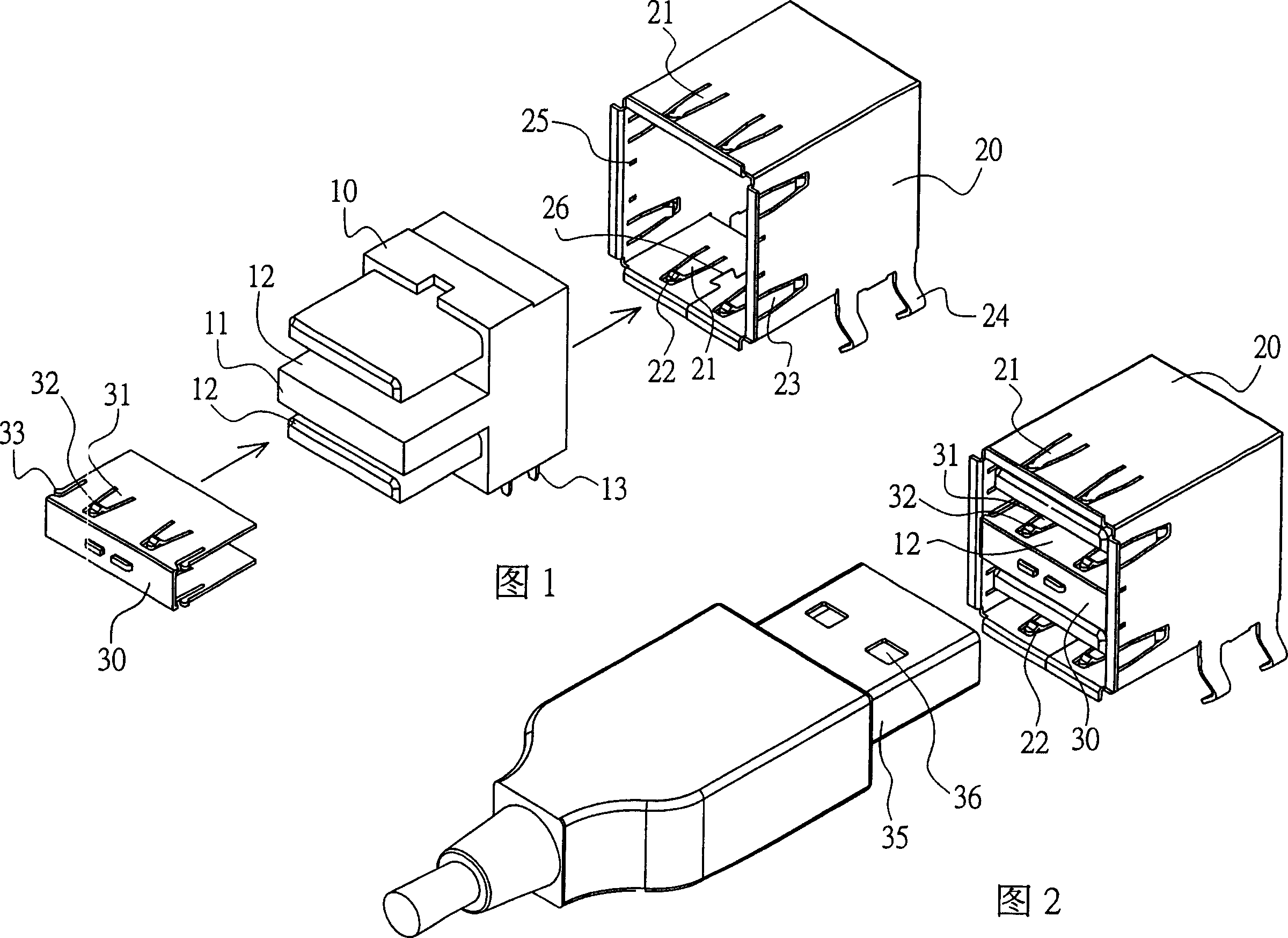

A technology for electrical connectors and connecting grooves, which is applied in the direction of connecting parts to protect grounding/shielding devices, etc., and can solve the problems of insufficient strength, loss of aesthetic feeling, and increased volume of buckle shrapnel 21

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

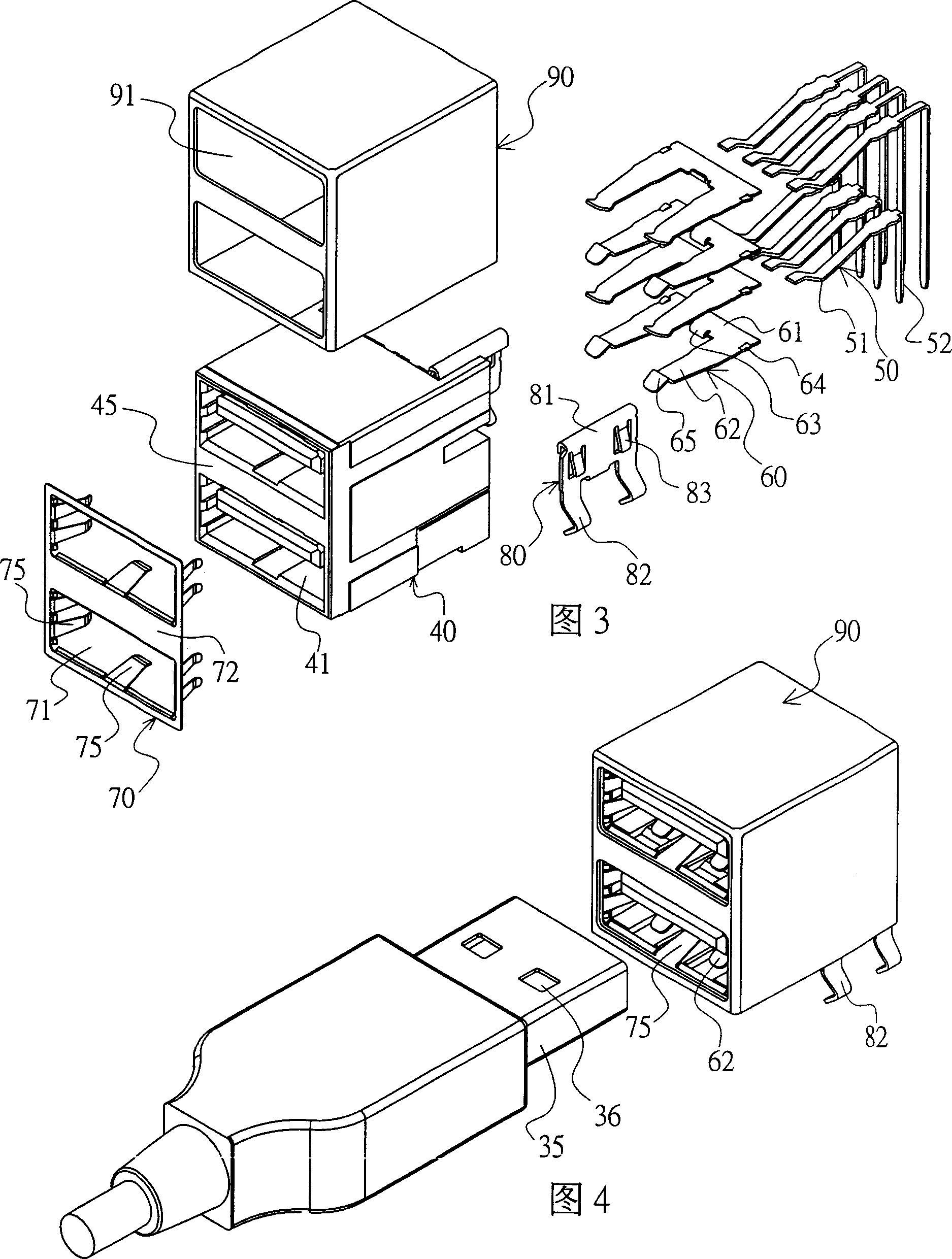

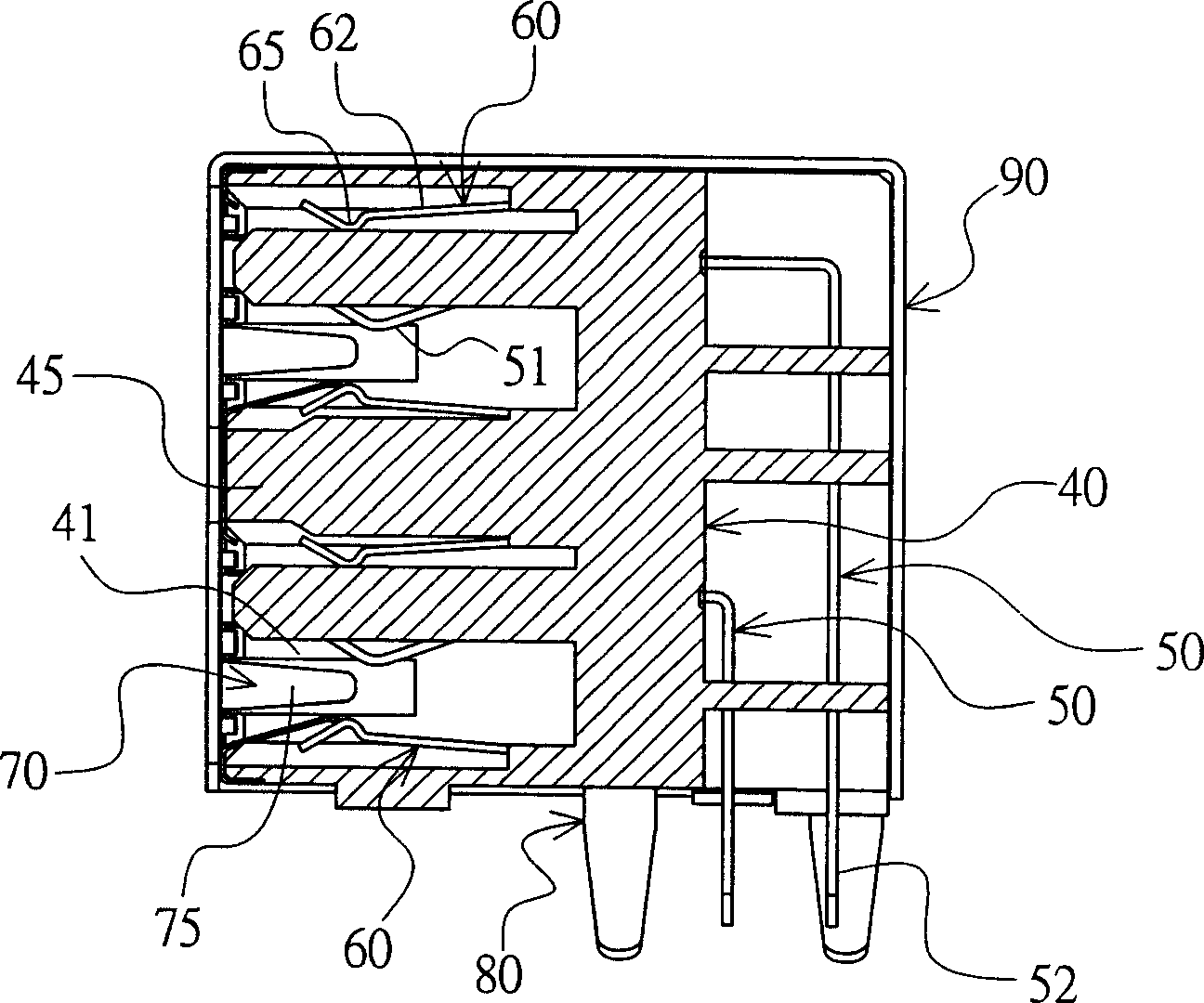

[0051] Please refer to Figure 3, Figure 4 and Figure 5 , is the first embodiment of the present invention, which is a double-layer USB electrical connector, which is used to electrically connect a USB connector 35, and the USB connector 35 is provided with at least one card hole 36, which includes: a plastic Base body 40, four buckle elements 60, a grounding element 70, two clamp elements 80, and a metal shell 90, wherein:

[0052] The plastic seat body 40 is provided with at least two connecting grooves 41 and a plurality of terminals 50. The front end of the connecting groove 41 is an insertion port for the USB connector 35. Please refer to Image 6 As shown in Fig. 7, two socket slots 42 and a stop surface 43 are respectively provided behind each connecting groove 41, a partition 45 is arranged between the two connecting grooves 41, and each terminal 50 is provided with a contact portion 51 located in the connecting groove 41 and a pin portion 52 extend to the lower end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com